Knauf Automotive

Car structure

Innovation in car design – a technological advantage

The automotive industry is on the threshold of revolutionary change, seeking innovative solutions that not only improve the performance and safety of vehicles, but also enhance their sustainability. In this process, lightweight construction materials, advanced aerodynamic technologies and intelligent safety systems play an important role. As a leading automotive parts supplier for automotive manufacturers, we remain at the forefront of this transformation, offering comprehensive solutions that drive the future of motoring.

Latest articles

Car structure

SUV is the most common type of vehicle of choice today. Why should you choose an electric SUV or a hybrid?

See more

Tier 1 and OEM car parts – What does the manufacturing of car components for OEM and Tier 1 look like?

See moreInnovation in car design

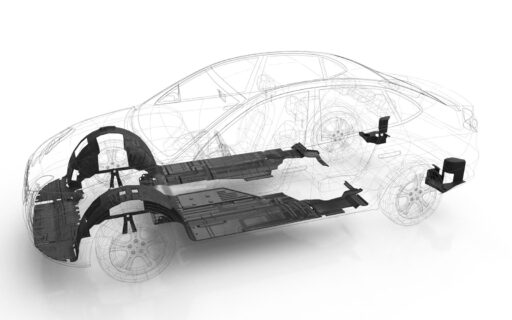

One of the major trends in the automotive industry is the drive to reduce vehicle weight. Manufacturers are turning to materials such as aluminium, carbon composites and modern metal alloys to achieve this goal. The use of lightweight components translates directly into improved fuel efficiency and reduced CO2 emissions, which is essential in the context of tightening environmental standards.

Read also: Construction of car bodies and production of their components

Aerodynamics

Innovations in car design also include the development of advanced technologies to improve body streamlining and reduce drag. Manufacturers are increasingly turning to dynamic elements such as movable spoilers or adaptive radiator grilles that actively adapt to driving conditions, increasing the energy efficiency of vehicles.

See: What is the difference between a car chassis and a platform?

Advanced safety technologies

Passenger safety remains one of the highest priorities among car manufacturers. The design of vehicles is being strengthened in sensitive areas, providing better protection in the event of a collision. At the same time, cars are being equipped with advanced driving assistance systems, including sensors, collision radar and adaptive cruise control systems, which increase the level of active safety.

Use of EPP and EPS in car construction

Modern plastics such as expanded polypropylene (EPP) and expanded polystyrene (EPS) also play an important role in innovative car design.

The role of EPP in car construction

EPP plays an important role in the fabrication of crumple zones and passenger protection components. The material is commonly used in bumpers, child seats and vehicle side reinforcements. Thanks to its high efficiency in absorbing energy during a collision, EPP effectively reduces injuries to car occupants. In addition, EPP allows for a significant reduction in vehicle weight, which directly improves fuel efficiency.

Use of EPS in car interiors

EPS is used in car interior trim such as door side panels, seats and dashboard. The material has excellent cushioning and insulating properties, which translates into increased comfort and driving safety.

Learn about EPP and EPS car components manufactured by Knauf Automotive.

Technological advantages of EPP and EPS

The use of lightweight and advanced plastics, such as EPP and EPS, in car construction brings a number of technological advantages.

Vehicle weight reduction

The use of lightweight materials, such as EPP and EPS, is key in the design of green and efficient cars. Reducing the weight of the vehicle translates directly into better energy efficiency and lower fuel consumption.

Improving safety

The absorption properties in pariticular of EPP provide effective protection for passengers in critical situations. These materials allow for better crash energy management compared to traditional structural components.

Comfort of use and durability

Due to its excellent insulating properties, EPP and EPS are often materials of choice for soundproofing a car’s interior, increasing driving comfort. In addition, EPP and EPS are characterised by their high resistance to moisture and chemicals, resulting in wide-spread use in many automotive applications.

Worth knowing: How does an electric car drive work?

The future of automotive design innovation

The automotive industry is constantly on the lookout for new developments that will drive car design in the coming years.

Development of new hybrid materials

Manufacturers are constantly working to develop materials that combine the advantages of EPP and EPS, such as lightness and absorption properties, with even greater strength and recyclability. Composite technologies and nanotechnology are opening up new perspectives in this field.

Increasing energy efficiency

Innovations in car design and aerodynamics, supported by the use of lightweight materials, will be important in improving energy efficiency, especially in the light of the growing popularity of electric and hybrid vehicles.

Sustainability and the environment

The future of plastics recycling in the automotive industry seems promising. Electric vehicles, 3D printing and sustainable development are all encouraging innovations that could change the way automotive parts are manufactured. More and more automotive companies say they are increasing the proportion of recycled materials in their products. We produce automotive parts from sustainable plastics for the automotive industry, such as the innovative rEPP plastic with the addition of raw material produced from post-consumer recycled waste.

Another interesting solution consists of bioplastics or sustainable biomass plastics, such as NEOPS® . Its technical properties are identical or even better than those of the traditional material, but it leaves a smaller carbon footprint. The raw materials used in the production process of traditional polystyrene have been replaced by non-food green waste according to the Mass Balance method. Unlike traditional plastics based on fossil fuels, this solution does not deplete resources and is less harmful to the environment.

It is worth noting that EPP and EPS automotive components are 100% recyclable, making them a sustainable solution.

Given the fact that today’s cars contain more and more components made of plastic, such as interior trim, bumpers or sun visors, the use of recycled plastics is a very important step towards more sustainable production.