Today, competitiveness in the automotive sector is all about the details. However, the larger elements cannot be overlooked – the engine splash shield is a key component whose parameters have a huge impact on the vehicle's performance on the road. Therefore, it is worth ensuring the use of a design that will fully meet the needs of the driver.

The function of the underbody shield: protecting the engine as well as improving the aerodynamics of the vehicle

The main task of the underbody shield is to effectively protect vital parts of the powertrain and steering system, but this is not the only function of such solutions. Considering the importance of the driving experience for customer satisfaction, it is definitely worth paying attention to this aspect when designing and manufacturing a car. The underbody shield has a significant impact on the quality of the driving experience – primarily on acoustic comfort. This element should absorb the shocks generated by the undercarriage and the engine during travel, thereby reducing the noise level in the cabin.

Another important aspect of the engine splash shield is to support the aerodynamics of the undercarriage. Using this component significantly improves airflow and reduces the impact that air resistance has on the handling of the car. As a result, the car can achieve higher speeds and lower fuel consumption, while the driver can expect better handling and a more precise response to steering when cornering. While the focus on optimizing the body performance is equally important, the importance of the car's undercarriage for driving physics cannot be overlooked.

In the construction of a car, almost all the parameters of the individual systems affect the other parts. For the best results, therefore, they must be considered as a whole. This is especially important when it comes to the fast-growing electromobility market – in this case, it's worth paying attention to the less obvious aspects of underbody shields.

Thermal management – an important strategy for vehicle design in the age of electromobility

The evolution of the market is imposing significant demands on certain aspects of design that were not considered some time ago. Nowadays, the engine splash shield has to not only function as a component that improves vehicle performance and cabin comfort, but also must respond to the needs of the electric car sector. Thermal insulation is crucial here due to the physical parameters of the components that are currently being installed.

The battery is the most important piece of equipment in an EV. Therefore, it is extremely important that it is properly protected. The battery covers for EVs and hybrid cars manufactured by Knauf Automotive excel at absorbing heat and shock, allowing battery cells to perform more efficiently regardless of the season or road conditions. Providing additional support for mild hybrid and EV designs to reduce weight (a key factor in energy consumption while driving), among other things, is definitely a good choice.

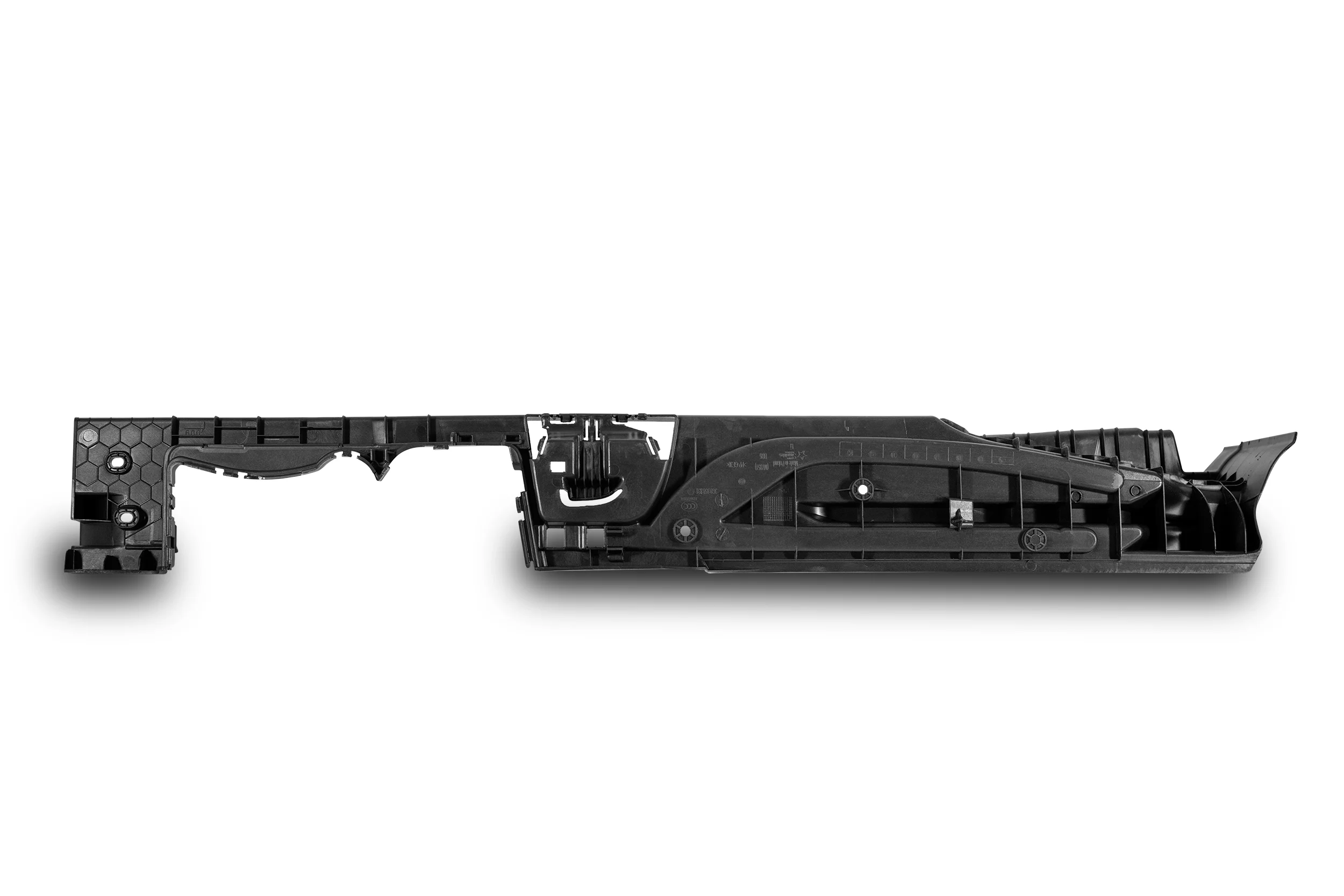

Engine splash shields – injection molding as an efficient method of production

In order for the lower engine cover to optimally support the vehicle structure, it must be made of an appropriately durable material that provides protection against mechanical damage as well as acoustic insulation. The use of injection molding in the manufacturing process of engine splash shields is a solution that is gaining increasing popularity among companies interested in optimising production and increasing the precision of manufacturing this type of components.

Here are the most important advantages of elements made using this method:

- Very good properties for driving physics – injection-moulded parts are light, which means they do not interfere with the forces exerted on the vehicle. At the same time, they maintain optimum stiffness and streamlining, so the aerodynamics of the undercarriage and other components remain at a high level.

- High durability – components manufactured using this method are resistant to the most common mechanical damage, such as impacts with small stones or dust. Their durability makes it possible to maintain optimal physical parameters for a long time during the operation of the vehicle.

- Excellent insulation properties – such elements provide effective protection against low temperatures and also contribute to the improvement of acoustic comfort inside the cabin. The injection-moulded engine splash shield is able to efficiently absorb any unpleasant shocks, which in turn contributes to a much better driving experience.

- The possibility for the structure to be freely adapted to the needs of the project – due to the considerable importance of the engine splash shield for aerodynamics, it is worth developing a design that will provide the best support for the vehicle structure. In the case of injection-moulded components, it is relatively inexpensive to produce high-precision parts, which gives engineers involved in driving physics a lot of room to manoeuvre.

Consequently, it is clear to see that the sum of these features applies equally well to conventional vehicles that use an internal combustion engine and especially to EVs, HEVs and cars with other potential drive systems. The durability, comfort and aerodynamic benefits are something that every customer will appreciate, while the freedom to implement modern solutions and shape components to suit the needs of a particular design is highly appreciated by manufacturers and designers.

Comprehensive solutions for the vehicles of the future from Knauf Automotive

As a company that is contributing to the development of the electric car market in Europe and around the world, we offer effective injection-moulded solutions for even better driving performance. We manufacture engine splash shields, as well as developing and producing a variety of products to support insulation, reduce vehicle weight and maintain a high level of safety. With a wide range of absorbers and individual components, combined with extensive experience in implementing these solutions, Knauf Automotive is able to provide customers with maximum satisfaction.

Have a look at our offer of injection molded car parts and do not hesitate to contact our engineers to find the best solutions for your needs!