Knauf Automotive

Production management

Efficient production management in the automotive industry

What should manufacturing management look like these days? Modern companies use various methods to realistically increase the productivity of the factory. We present the most important information on production and operations management, which prove useful especially in the automotive industry.

Latest articles

Production management

Popular Articles

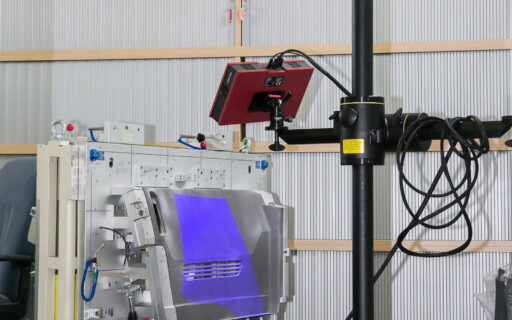

What benefits does 3D scanning provide in the area of quality control in the automotive industry?

A modern approach to manufacturing management – methods, definitions, solutions

Manufacturing management is the key in the automotive industry. How to increase efficiency and improve work organization?

What is manufacturing management?

Serial production, i.e. the manufacturing of a series of identical products, requires the use of proven techniques and proper process control. For starters, however, it is worth defining more precisely what manufacturing management actually is. The term refers to a wide variety of issues – in particular, the various steps that need to be taken to ensure the required production efficiency and quality. Manufacturing management usually takes the form of a complete process that involves planning, organizing, directing and controlling tasks from the initial to the final stage. These are issues that are of considerable importance in any production facility – but it is worth bearing in mind that their role increases with the scale of production and the emergence of new requirements.

Modern production and operations management is particularly important for manufacturers in the automotive sector, where the enormous complexity of processes, high market expectations and the need to comply with various complex regulations must be taken into account. Car design and production are tasks that begin with the concept stage – for example, with a customer order. After the initial design is prepared, one can already move on to the development of schematics of specific components with details. The next stage is usually the creation of a test piece. Manufacturing management is important at each and every of these steps – until the completed product leaves the warehouse and reaches the customer. Such processes are used to make various types of custom solutions, such as Tier 1 and OEM automotive parts.

What constitutes manufacturing management?

A key element of modern manufacturing management is the organization of production processes. Tasks in this field affect the speed of work and the quality of final products. The organization consists of specific issues related to parts, teams or positions – the main goal is to define the links and responsibilities in each area, which allows to maintain high efficiency and full control over production.

Production organization is the basis of many concepts that have been used for years in the automotive industry, such as lean manufacturing. This is an approach that we actively use at Knauf Automotive, which allows us to increase production efficiency while reducing costs and optimizing working hours. With such a model, it is possible, among other things, to significantly improve the time-to-market parameter, i.e. shorten the time to market for a new product, without sacrificing quality.

What is a production plan?

In addition to production and operations management, another vital element of the process is the production plan. The purpose of the plan is to determine the volume of items to be produced within a certain time. However, that’s not all – any possible impediments that could extend the production time also need to be taken into account. These could include supplier delays or machine breakdowns. With a properly prepared plan, production can be managed much more effectively and the negative effects of various unexpected situations may be minimized.

What is modern manufacturing management?

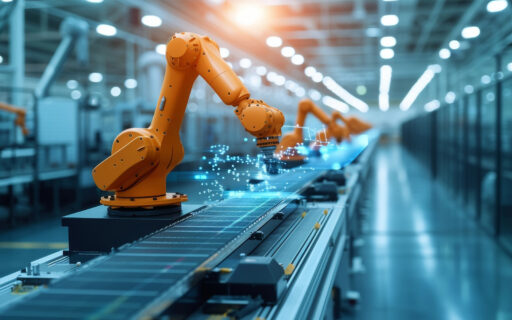

What should modern manufacturing management look like? What matters in this area is the use of new technologies and proven management methods. This allows you to significantly increase productivity and improve the pace of production, while reducing the risk of failures, errors or material losses. Among other things, robotization and automation of production play a vital role in this regard. Solutions in this area allow to maximize the efficiency and precision of plant operations. Also the possibility of collecting data from sensors on an ongoing basis provides a considerable advantage – IT systems supporting manufacturing management use this information to enable even more precise control over the course of the entire process.

Manufacturing management should also include issues such as production process mapping and quality management. Their correct implementation translates in practice into increased efficiency of the entire system. However, it is worth knowing which technologies to invest in – for this purpose, specialized knowledge and a thorough analysis of the operation of the company or its specific departments will come in handy. It is a good idea to follow proven methods and concepts, such as the factory of the future (Smart Factory).

Manufacturing management at Knauf Automotive

At Knauf Automotive, we are well aware that production efficiency is crucial. That’s why we are constantly developing with proven management methods, robust materials and latest technological solutions. We specialize in plastic products for the automotive industry – with the right approach to concepts such as working with WIP limits, we are able to ensure high product quality, consistent performance and minimal time to market. If you are interested in choosing a manufacturing partner, please see our offer for manufacturers in the automotive sector.