We are Knauf Industries, and we are an experienced designer and manufacturer of expanded foam components for automotive battery packs.

Knauf Industries belongs to a group having a long-standing tradition of research and technological development, and we promote and develop innovative products to support our customers’ strategies and growth pillars. We support automotive manufacturers in their efforts to reduce emissions, for instance, by way of enabling the increased use of lightweight construction materials for passive safety systems. Furthermore, we design and manufacture expanded foam components for automotive battery packs, offering high-performance solutions for electromobility.

Car Battery Pack - Knauf Automotive

We at Knauf Industries use our experience as a long-standing partner to the automotive industry and its actors, to develop insulation solutions for battery systems for commercial vehicles and passenger cars.

Our Research and Development Department, ID Lab®, supports our engineering and plant teams all around the world, and aids our customers in solving issues and boosting innovative solutions.

Car Battery Pack

Our many years of experience in the automotive industry and our expertise as insulation solutions supplier are reflected in the development of our e-mobility business.

A further focal issue for us is the strengthening and improved integration of car battery expertise across all fields: R&D, engineering, prototyping, production and recycling solutions.

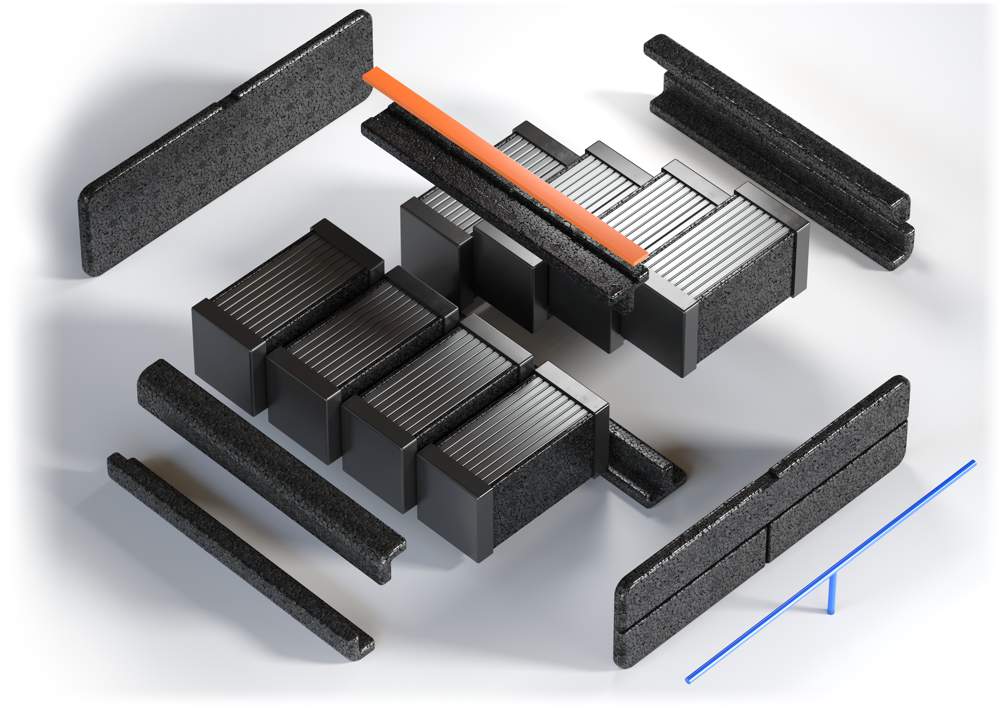

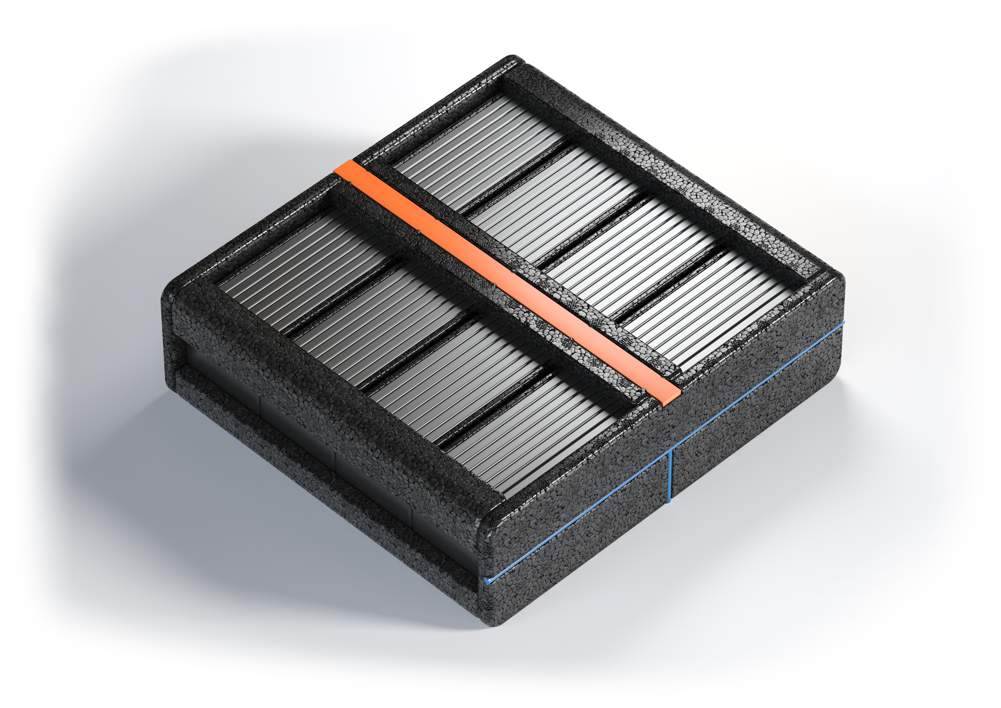

Expanded foams for car battery elements – busbar/cooling pipe/electric cable guiding, cell separators or/and insulators, shock-absorption.

-

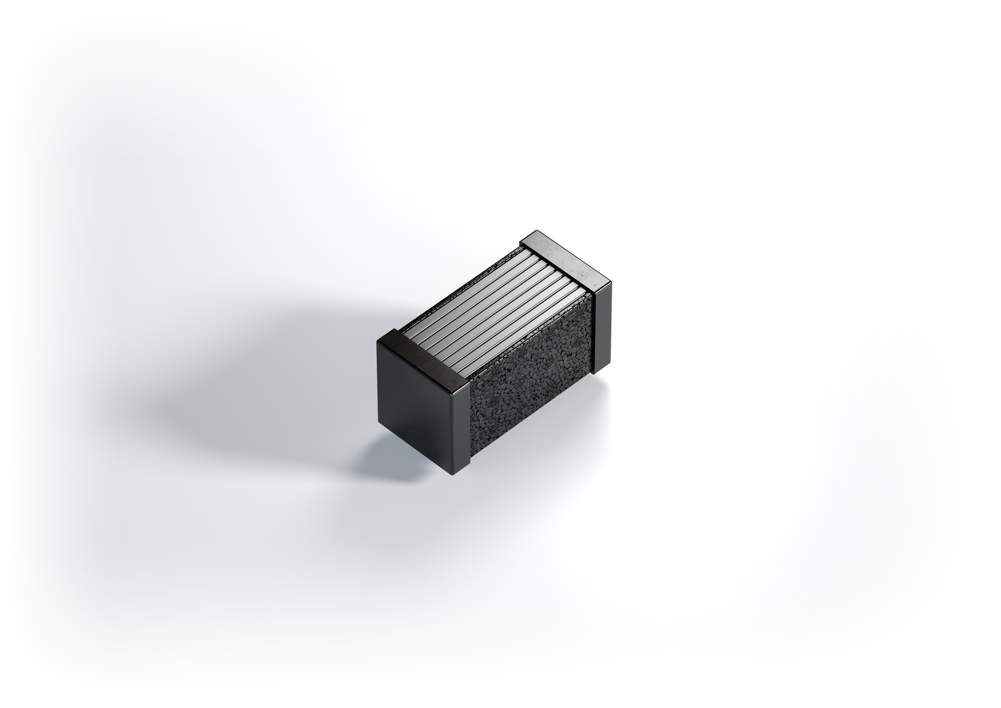

Cell pack

We make cell separators (thermal insulators) and in more general the battery pack where we intervene on the absorption of side shocks, superior absorption, for example, with functions of bus bars or cooling pipes.

-

Thermal and electrical insulation

In addition to batteries shock protection, our parts reduce the risk of battery’s internal defects during real life usage.

The high thermal insulation performance of our materials reduces heat transfer between battery components, eliminating the risk of thermal runaway.

Our expanded foam materials have also a very high breakage voltage value, which helps to diminish the risk of current flow between cells.

-

Fixing function

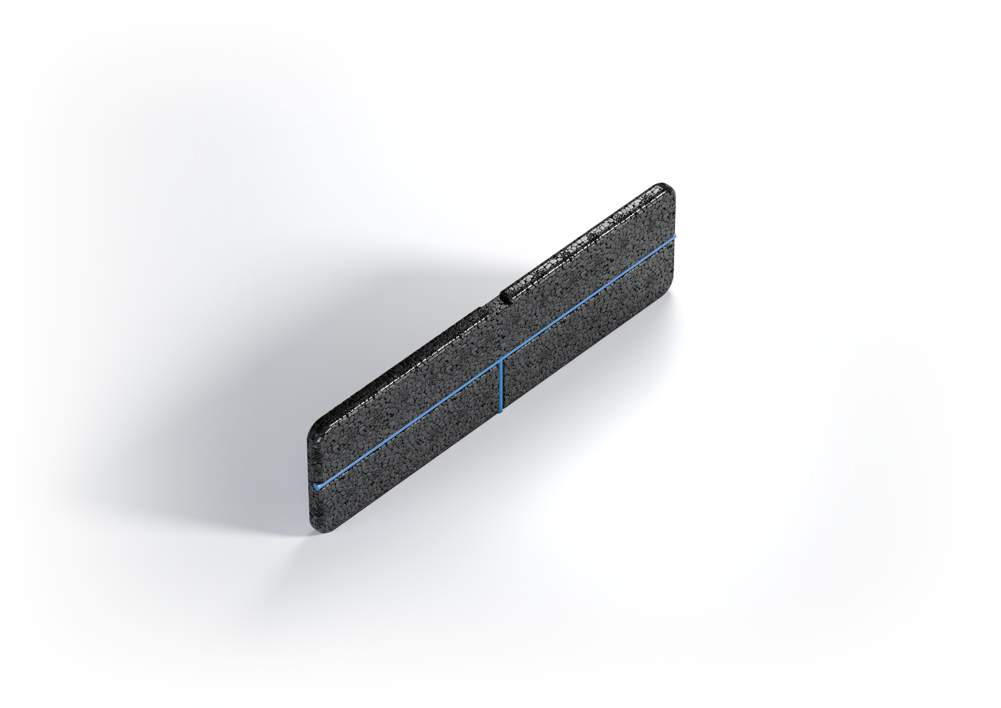

Our parts also have a guiding and fixing function. We offer various components for connecting batteries and battery packs - such as bus bars. Our foam components serve perfectly as electric wiring fixing elements, facilitating the battery pack assembly.

Expanded foam components can eliminate the standard way of fixing of the battery elements by screwing or using additional parts. With foam fittings by Knauf Industries, the battery pack components are attached by manual snapping without using any tool or additional parts. Thereby, the assembly process is faster and less expensive.

We offer our parts for suitable battery solutions with the following added value:

- Lightness

- Thermal and electrical insulation

- Guidance and fixing

- Shock absorption

The most frequent questions about car battery technology

Why install car battery insulation?

Thermal management is a key element to guaranteeing optimum performance and life of battery packs, and also to reducing uneven distribution of temperature throughout a pack - which leads to reduced performance.

When to use foam-based car battery insulation?

This can be applied when you want to combine lightweight thermal insulation performance with respecting the environment through using recyclable materials.

Will a car battery melt foam insulation?

No, if required, we have fire retardant solutions compliant with UL94 standard. Moreover, it’s worth mentioning that high peak temperature resistance of our foam materials eliminates melting risk during temperature demanding phases like fast charging.

What are the functions of the foam components of a car battery?

We provide solutions for many cell pack/module functions and battery pack environments:

- Lightweight: One of main challenges in EV vehicle design is to contain vehicle weight. By using expanded foams (like expanded polypropylene – EPP), you decrease significantly the weight compared to other solutions like plastic injection.

- Shock/Vibration absorption: Battery packs are very sensitive to vibration and shock absorption, and EPP material properties bring solutions to this.

- Thermal / Electrical insulation: These EPP properties will support efficient BMS (Battery Management System) operation by increasing performance of the battery pack.

- Fixation: By using EPP to embed cooling pipes, electric cables and/or busbars, you simplify the assembly process by reducing the number of components.

- Others: We can provide other solutions according to the demand, like desiccant bag support.

Contact our engineers

Our customers thereby benefit from our high level of development expertise in the area of foam materials and from our experience in the optimization of worldwide production processes and supply chains.

Our car battery insulating components are solutions for car battery manufacturers that reduce development time and cost for the vehicle manufacturer. The automotive battery pack insulation and shock absorption elements are easy for engineers to configure for use on virtually any vehicle platform. Contact our engineers for more information about foam car battery components.

- Nicolas Moreau

- Automotive Head of Development

Product & Advance Design Manager - Tel.: +33 (0)6 79 51 70 75

- [email protected]om