ASSEMBLY OF AUTOMOTIVE COMPONENTS

Manufacturing plastic parts is just a single process in our extensive range of services. We also provide many other services that deliver added value to our customers – one of which is the assembly of automotive components. As a result, companies working with us can receive products that are fully prepared for the market, and thus the time to market (Time To Market) is reduced.

During the entire process of designing and manufacturing injection molds, our experts provide their extensive theoretical and practical knowledge, as well as years of experience. We can effectively optimize the injection mold to fit the customer's needs. Our support also includes the actual production of the finished product. See how the various stages of cooperation look like.

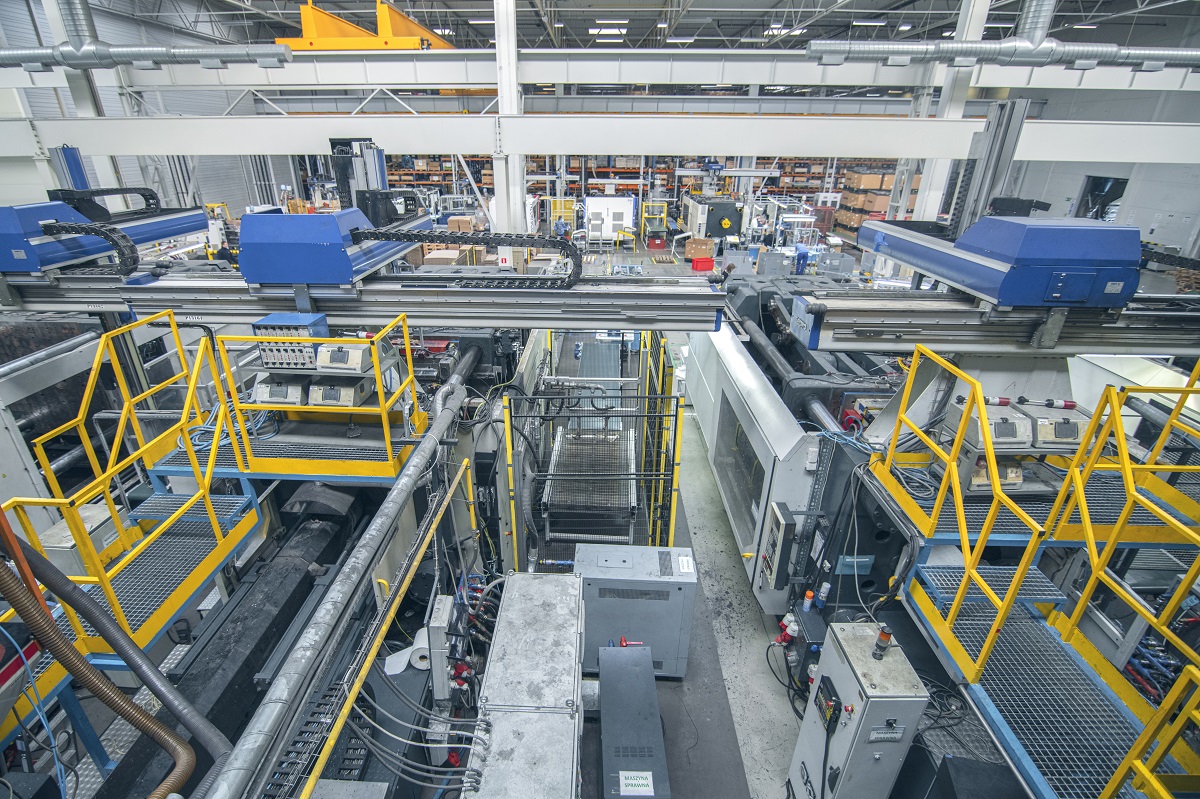

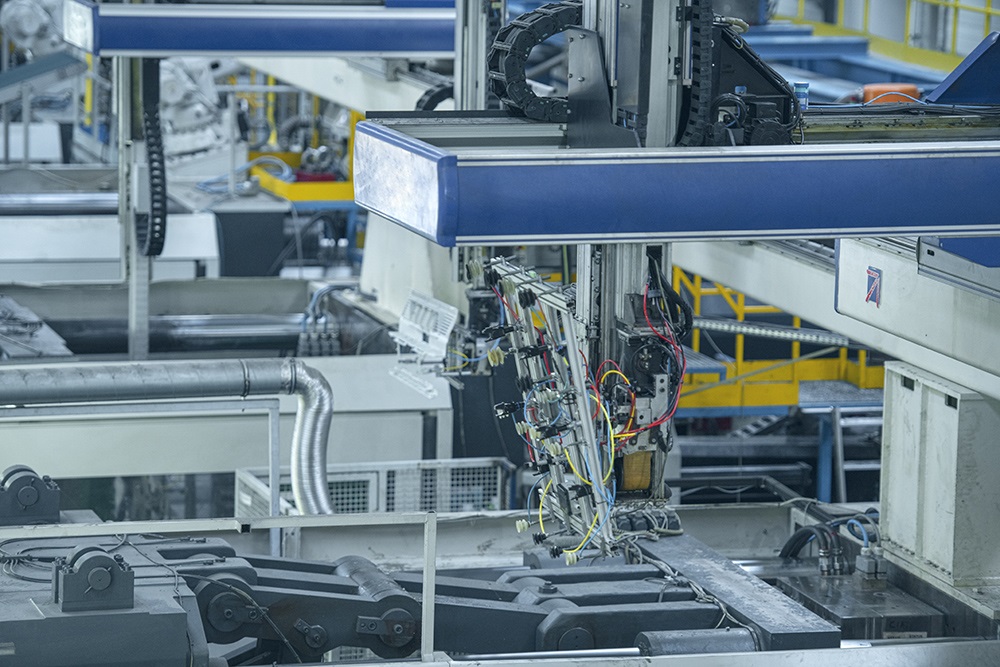

Assembly of automotive components is a post-production service that includes, among other things, multi-step procedures performed with advanced assembly robots. The use of such equipment ensures maximum efficiency, precision and repeatability – factors of great importance during mass production. Automation and robotization of production are a proven way to optimize manufacturing processes and increase safety. It also relieves staff of monotonous tasks, allowing employees to focus on more responsible, creative and valuable tasks.

For the assembly of automotive components, we use five- and six-axis articulated robots that are capable of moving in several planes. One of the major advantages of such solutions is the ability to set any orientation, which makes the machines suitable for both assembly and many other applications. We are talking about product handling, machining, as well as transportation, among others.

AUTOMOTIVE PARTS MOLDING WITH ASSEMBLY

Injection molded parts manufactured by Knauf Automotive can be ordered with assembly, a service in which we offer our customers finished products for the automotive industry. We deal with components for use both outside the vehicle and inside the passenger compartment. Knauf's product portfolio includes, among others: dashboard components, steering column pads, air vents, center consoles, roof modules, fenders, grills or sensor mounts.

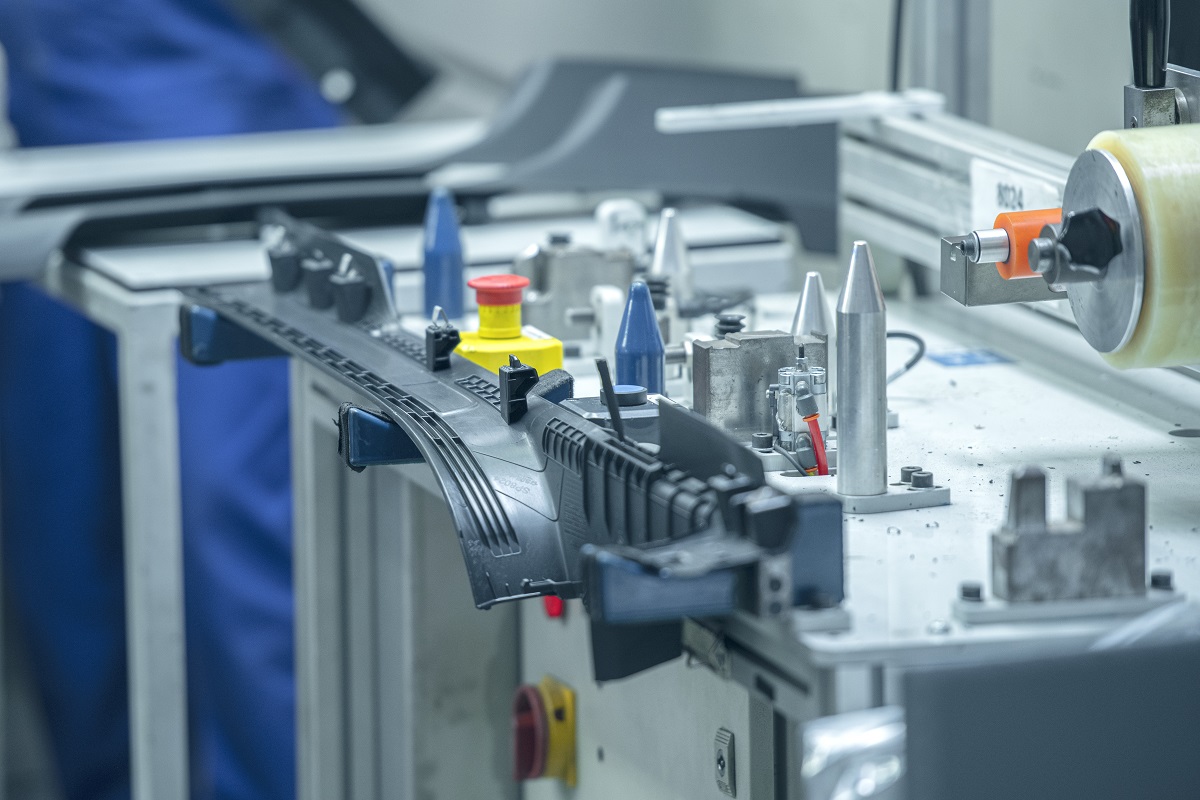

ELEMENTS OF THE ULTRASONIC WELDING AND SURFACE ACTIVATION PROCESS

Injection molding car parts can also combine with other assembly processes, which are used, for example, in the production of car door panels. After being injected into a mold, plastic parts are removed from the mold by 6-axis robots. Unnecessary parts are then cut off, and the entire part is flame treated on the edges where the tape is ultimately placed. Combined with clips, this makes it possible for components such as panels, moldings or sills to fit tightly to the body and provide the desired effect. Assembly processes can be divided into inline and offline – those that take place on the production line or at a separate, dedicated assembly station.

Such activities include ultrasonic welding, which uses the energy of high-frequency acoustic waves. This makes it possible to join parts very quickly in an efficient manner without the need for chemicals such as solvents or adhesives. Activation of the surface by the aforementioned flame treatment also plays a crucial role. Flame treatment allows the surface to be highly polarized, which in turn increases its adhesion, i.e. the bonding strength of different materials.

AUTOMATED ASSEMBLY LINE

The use of robots in the automotive industry is of particular importance. This is a sector where it is crucial to maintain quality standards related to strict safety standards, among other things. Currently, the most important goal of using robots and automating the production line is to improve the quality of work that requires greater precision of operation. The use of such solutions makes it possible to significantly shorten the production cycle and increase the accuracy of the entire process. On an automated production line, it is the machine that is responsible for maintaining the right pace and eliminating errors, while human tasks are limited to control functions.

PROFESSIONAL STAFF AND ADVANCED MACHINE FACILITIES

Robotization and automation of production requires, above all, effective cooperation between man and machine. Modern robots used in our plants perform complex operations under the watchful eye of a human operator, who, thanks to appropriate equipment, does not have to perform monotonous, difficult and sometimes dangerous operations. During the production and assembly of automotive components, robots are most often used in the form of an arm or several arms. They provide a very large working space, fast and precise movements and flexible assembly options.

INDUSTRY 4.0

It should be noted that technology and assembly automation are constantly evolving. Already, several important trends can be distinguished that will play an increasingly important role in the automotive market in the near future. Among them are the use of robots and the possibility of seamless data exchange within the framework of IoT and Industry 4.0 solutions. As Knauf Automotive, we keep a close eye on the development of production and assembly methods in order to be able to continuously provide our customers with the right standard by using the most valuable innovations.

A RELIABLE SUPPLIER OF PLASTICS AUTOMOTIVE PARTS

We are an international plastic parts supplier. We are distinguished by many years of experience and professional knowledge, which we are constantly developing during the implementation of subsequent projects. Thanks to this, we are able to guarantee that every project, even the most difficult, will be carried out at the highest level, with attention to all details. Outsourcing production is a good solution for companies in the automotive sector in terms of reducing costs, optimizing processes and taking advantage of innovations offered by trusted contractors.

Download case study of cooperation in one-stop-shop model

The selection and evaluation of suppliers in the automotive industry has very important significance. No matter what the project will be about, it matters to properly specify the criteria for selecting partners in order to ensure effective cooperation, increase efficiency, and minimize the risk of losses. At Knauf Automotive, our first priority is customer satisfaction – that's why we constantly maintain the high quality of the automotive components we produce. If you are interested in cooperation with our company, do not wait and contact us!