Fuel consumption is an important issue not only from the perspective of the costs of operating a car, but also the impact on the environment. It is worth knowing what is the average consumption for a car, how to calculate it and how to improve it. The amount of fuel burned per 100 kilometers depends on many factors – some of them are directly influenced by the driver, while others are the result of the vehicle's design.

What determines the fuel consumption of a car?

Depending on the vehicle, average fuel consumption can vary from about five to even more than a dozen liters per 100 kilometers. The differences between individual cars are primarily due to the size of the engine, technical condition and design, as well as the driver's driving style. It is worth remembering that expenses on fuel constitute a large part of the costs of operating a car. What is more, cars are responsible for about 15% of carbon dioxide emissions in the European Union, and the combustion of one liter of fuel generates from 2.35 kg (petrol) to 2.6 kg (diesel) of CO2. Such a high contribution to pollution makes it important for every driver to know what fuel consumption depends on and how it can be reduced.

The size and power of the engine as well as the technology used in the drive unit have a significant impact on fuel consumption. If you want to reduce fuel consumption, it is worth buying new models, which are often equipped with additional solutions reducing emissions of harmful substances. It is also important to pay attention to the quality of fuel, as well as the technical condition of the vehicle and the cleanliness and efficiency of individual components.

Driving style and fuel consumption

The driver also has a large influence on fuel consumption – it is particularly important to drive in a smooth manner, i.e. to avoid sudden acceleration and braking. The proper use of gears is another factor that can reduce fuel consumption. It is also good practice to use engine braking and keep a close eye on the engine speed to be able to shift up a gear as quickly as possible. You should also learn how to calculate fuel consumption.

How to calculate fuel consumption?

When searching for the answer to the question "what is the fuel consumption of my car?", you should read the combustion reports or use a fuel consumption calculator. Calculations are very simple – simply divide the volume of fuel used by the number of kilometers driven, and then multiply the result times 100. There are many calculators online that facilitate this task. In addition, the vast majority of vehicles are able to display the current fuel consumption – it is also possible to check the fuel consumption over a given distance.

The car's on-board computer constantly monitors the status of many sensors, including those located at the fuel injectors. In combination with information about fuel pressure and other parameters of engine operation, the vehicle is able to provide an estimate of fuel consumption at a given moment.

Reducing fuel consumption at the car design stage

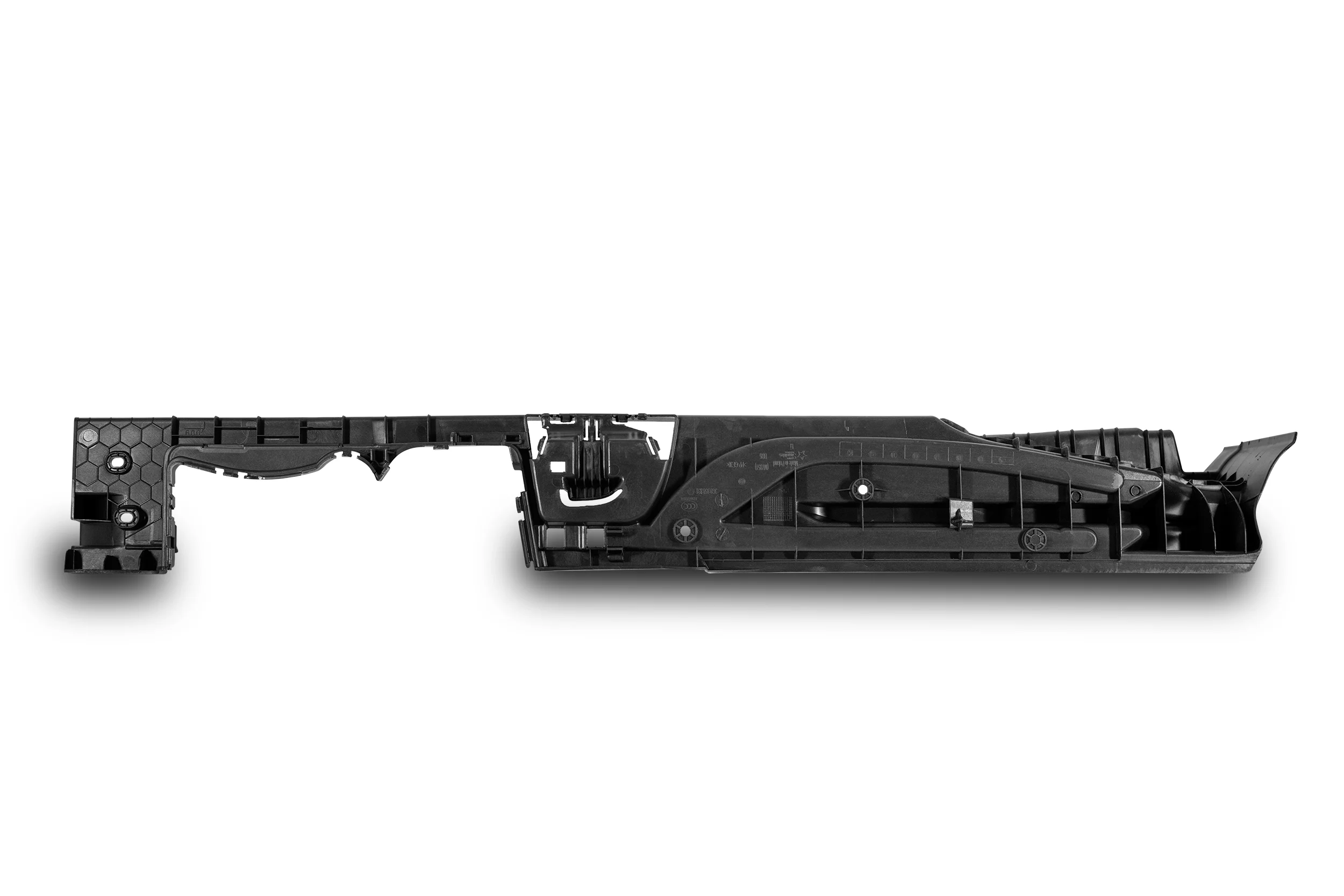

Modern design allows for a significant reduction in fuel consumption. Most components in cars are made of plastics, which significantly decreases their weight, and thus – the entire vehicle. For this reason, it is worth betting on materials that are primarily characterized by lightness, while providing the appropriate parameters in terms of strength and formability of individual components. The right choice of materials can reduce average fuel consumption by up to several dozen percent.

Vehicle design and energy efficiency of electric vehicles

Optimizing energy consumption is also important for electric cars. Although the very nature of their operation allows for a significant reduction in environmental impact, it should be considered that the electricity to power the engine often comes from unsustainable sources. In addition, the intensive use of the battery reduces its service life, forcing an earlier replacement of the battery and increasing demand for the production of such components, which can also produce various harmful substances. For this reason, drivers and manufacturers of electric vehicles should also pay special attention to energy efficiency – both in terms of design and driving style.

See also: The best examples and CSR methodology in Knauf Automotive

The use of modern materials such as expanded polypropylene (EPP) offers similar advantages as in the case of combustion engines. The biggest advantage is the reduction of the total vehicle weight – a factor that is directly related to energy consumption. EPP components also offer many advantages, for example in providing appropriate protection and insulation for lithium-ion batteries. The material's strength and excellent thermal insulation properties make it the perfect choice for this application, as well as for other parts in electric vehicles.

See also: Sustainable plastics – innovative materials for automotive sector

Knauf Industries – solutions for green vehicles

Knauf Industries is one of the leaders in the production of lightweight automotive parts made from plastics, in particular expanded polypropylene (EPP) and polystyrene (EPS). By using these materials, Knauf products can significantly reduce the weight of a car, which translates into lower fuel consumption. The flexibility of the materials also enables customized solutions to make components that fit perfectly into a given model. Knauf's manufacturing processes for lightweight EPP components include the use of injection molding technology.