When Carl Benz patented his Benz Patent-Motorwagen, the first motor vehicle in history, in 1885, he didn’t think to install bumpers. In his car design, which was essentially a tri-wheeler with large wheels, equipped with a combustion engine, the German motorization pioneer did not foresee the need to install parts and components that would have a decided impact on the evolution of car design and safety, despite the awareness that a collision with another vehicle might take place.

The first bumpers that we know of were installed in 1897 by the Czech manufacturer Nesselsdorfer Wagenbarr-Fabrïksgesellschaft, and solely for aesthetic purposes.

In 1901, the British engineer Frederick Richard Simms was the first to consider auto bumpers as playing a certain role in improvement of safety. In 1905, he filed a patent application for the buffer, claiming that its goal was to “prevent damage to reflectors, mirrors, radiator and other parts of the vehicle, which should be the last to collide with an obstacle, as well as for the purpose of protecting people or vehicles on the road”. He also explained that the “buffer” should be manufactured “similarly to pneumatic tires or made from solid rubber or filled leather”.

However car manufacturers did not take his specifications into account. As sales of new motor vehicles increased, steel strips were installed on the front and back of vehicles. Cars manufactured at the end of the 1920’s were heavy and dangerous. To improve protection, thin metal strips were replaced by double steel bars joined by two longerons.

AUTO bumper as a symbol of identity

In the 1930's and 1940's, car manufacturers began to utilize the aesthetic potential of bumpers. They joined them to the bodywork, emphasized their presence and played with their shape, transforming them into key components endowing a vehicle with personality.

Large, heavy and glossy, chromium-plated bumpers became the identifying feature of American brands, which were still exploring their design possibilities in the 1960's. They installed grates, lighting and even exhaust pipes in bumpers.

The first plastic bumpers were installed by General Motors in the Pontiac GTO model from 1968. This component was made from an elastomer called Endura, in the color of the car body, and was designed to absorb shocks at low speeds without permanent deformation. Similar bumpers were also installed in the Barracuda model from Plymouth (1970-71). Other companies installed rubber bumpers on metal rods to absorb shocks.

In 1973, the Federal Motor Vehicle Safety Standards entered into force. This was a breakthrough for the automotive industry in North America and for all brands exporting their vehicles to the United States.

Among other things, these standards defined the dimensions and safety functions of bumpers, which were to prevent damage to cars in the event of a frontal collision at a speed of less than five miles per hour.

All carmakers had to adapt the designs of the models they sold. Manufacturers did so with an aesthetic effect, as described in the didactic report The Bumper Cars (Hagerty, 2015). In the case of new models, the engineers did a much better job. Thanks to standards, passenger safety became a priority for the automotive industry in North America and is now taken into special consideration when designing vehicles.

Plastic BUMPERS enter the scene

Manufacturers did not have a choice but to reach for new materials – lighter, safer and more flexible, in order to aesthetically integrate bumpers with their vehicles. And so, chromium-plated metal disappeared due to its weight and costs (the petroleum crisis of 1973 also had an impact). Plastic began increasing in significance.

In Europe, bumpers were never treated as ostentatiously as they were in America. Research on new polymers was more advanced. As a consequence, in 1972, Renault became the first company to equip its popular R5 model with a plastic bumper.

In the 1980's, plastics solidified their position as the main protective component in vehicles. This function has evolved to the point that, today, bumpers perform an aesthetic function, similarly to their function at the beginning of their history. The front bumper is becoming ever larger so that it can fit fog lights, air intake grates, parking sensors…

PLASTIC BUMPER MANUFACTURING

Injection molding offers uncounted design possibilities, which, through the appearance of the bumper, make it possible to endow a vehicle with the personality desired by the brand: sports, offroad, family, etc.

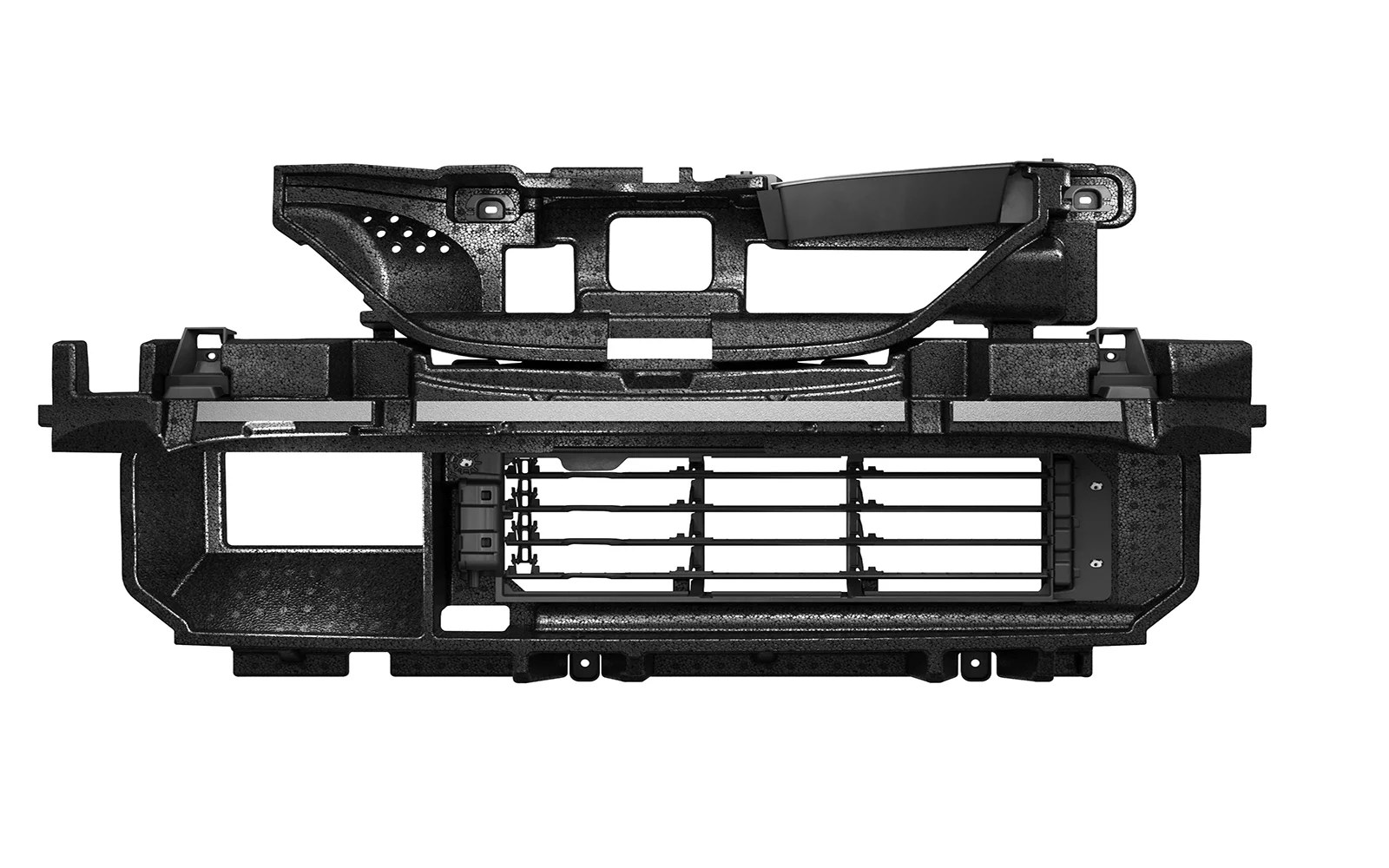

In contrast to the gleaming chromium-plated bumpers of the past, modern bumpers made of plastic cover the parts that authentically make cars much safer than before: shock absorbers, suspension, mudflaps…

And this is where the elementary work of suppliers of the automotive industry begins, suppliers like Knauf Industries Automotive – automotive plastic parts manufacturer and expert in production of auto parts made of expanded polypropylene (EPP), whose physical properties make it the best material for reducing the weight and improving the safety of cars.

Considering their century-long history, nothing seems to indicate that the evolution of bumpers will end here. What will they look like in twenty years?