The cooling system in a car performs many important functions, without which it would be impossible to provide the drive unit with optimal operating conditions. One of its main components is the car radiator. What does a car radiator do, how does this part work and what are its most important tasks?

How does the cooling system in a car work?

The cooling system in any internal combustion vehicle is started as soon as the engine is turned on. Its operation begins by setting the coolant pump in motion, which is responsible for transferring coolant to further parts of the system. It first circulates through a closed circuit without passing through the radiator. Only when it reaches the right temperature due to the extraction of energy from the heated engine does it enter the so-called “large circuit,” which includes the radiator. As a result, it is possible to maintain a stable operating temperature of the drive unit, as well as provide the necessary protection against overheating, which could have very serious consequences.

Cooling system vs air conditioning and electric cars

Just keeping the temperature at the right level is not the only function of the cooling system. Other applications of the system are also worth noting. These include the transfer of heat via the heater to the passenger compartment. Thus, the operation of the car's air conditioning and cooling system is to some extent related, although the systems themselves work separately. It should also be noted that the use of air conditioning can put additional strain on the cooling system.

The issue of air conditioning and the temperature of the engine itself is somewhat different in the case of electric cars, where the drive unit does not generate heat. For this reason, such vehicles use specially designed heating and cooling systems. This also means that air conditioning in electric cars is different from the systems used in combustion cars. Its method of operation is mainly based on the use of a special fan heater, although other solutions are often used as well.

Car radiator – construction and operation

The cooling system in a car consists of several parts, the most important of which is the radiator. It is mounted at the front of the vehicle and is distinguished by a very characteristic structure, which consists primarily of a series of narrow channels – this is known as a water jacket. The fluid that flows through these channels takes excess heat away from the engine.

How does a car radiator and cooling system work?

The principle of a car radiator is relatively simple. When driving, the momentum of the air cools the individual tubules, resulting in the hot coolant giving off heat. As a result, temperatures equalize – the coolant becomes cooler, while the space around the radiator heats up.

A very important element that guarantees the correct operation of the radiator is the fan. It is activated, for example, when stopping or standing in a traffic jam, because the momentum of the air cannot then take away the heat. In the context of modern cars, the electronically controlled thermostat should also be mentioned. It is equipped with a special valve controlled by the engine controller. With this solution, it is possible to manipulate the temperature of the coolant in such a way that the engine can operate at the optimal temperature regardless of the current load.

What materials are used to manufacture car radiators?

The main components of the radiator are most often made of metal (e.g. aluminum), while the upper and lower parts can be made of plastic. Innovative materials with special properties are also increasingly used in the production of such components. One of these is Kevlar, used to reinforce sensitive components such as radiator hoses. This is a synthetic polymer that is distinguished by its very high tensile strength and at the same time light weight, which is crucial in the design of automotive components.

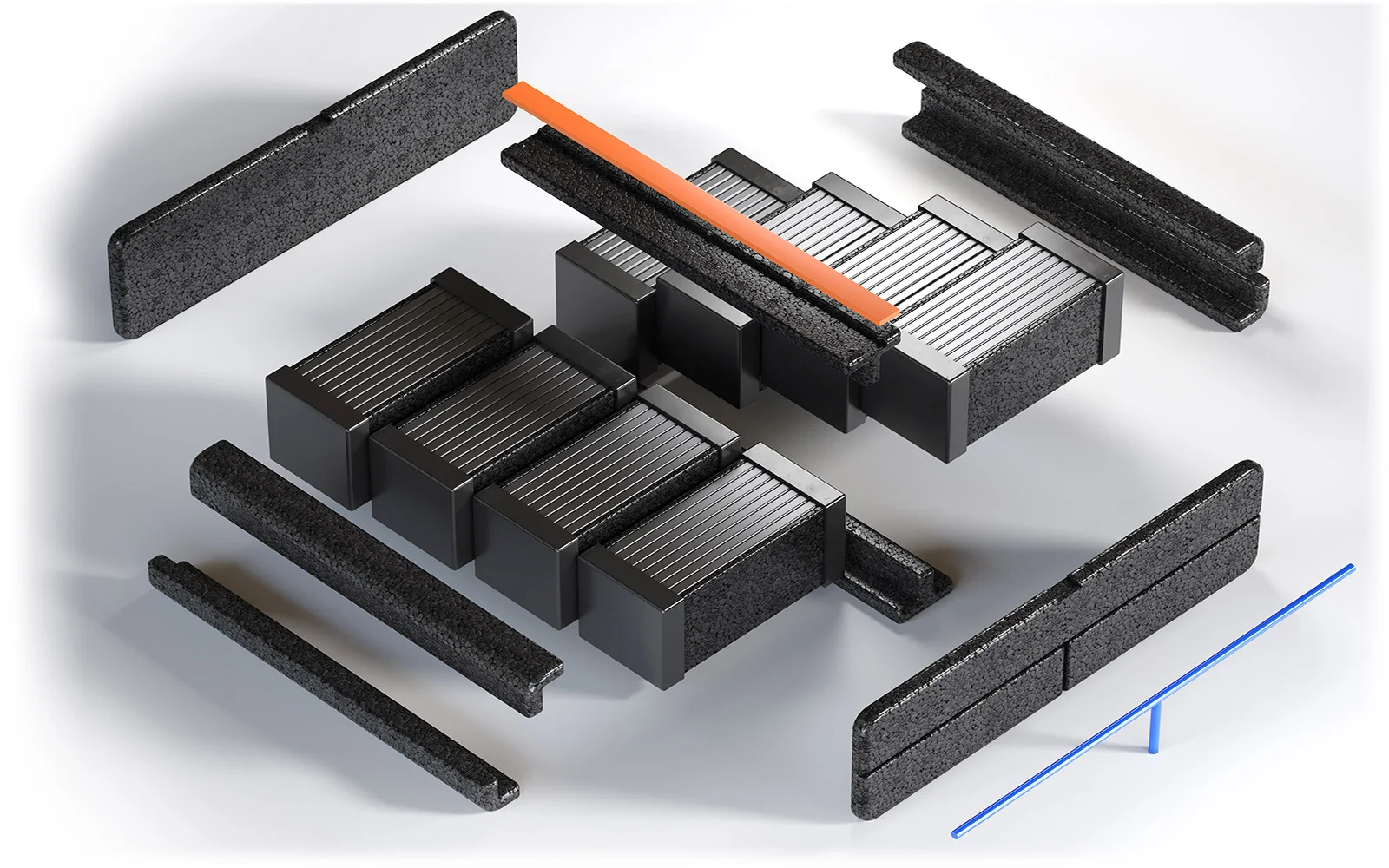

When it comes to the production of grilles, foamed polypropylene (EPP) injection molding technology is gaining popularity. This material has many favorable properties, the most important of which are excellent energy absorption and low weight. The use of this material guarantees the optimization of the total weight of the vehicle, as well as increased safety in the event of a collision.

Knauf Automotive – EPP and EPS automotive components

Knauf Automotive is a leading manufacturer of automotive components made from polypropylene and foamed polystyrene. We offer state-of-the-art solutions aimed at increasing productivity while being environmentally friendly. We supply reliable body components and the most necessary automotive accessories – manufacturing such parts as engine cover, radiator grille and other essential automotive components from EPP and EPS. Within our offer you can also find components for ventilated car seats, which are part of the equipment of the most luxurious vehicles. This is a special type of seat equipped with an additional system of forced air circulation, which translates into greater comfort while driving. Regardless of the type of product chosen, our customers can always expect expert support and reliable solutions with parameters properly selected to meet individual needs. You are welcome to contact us!