Knauf Automotive

Production efficiency

Maximising production – efficiency strategies

The automotive industry is facing a transformation to meet increasing market demands and environmental regulations. New technologies such as microfactories, Industry 5.0, digital solutions and additive technologies play an important role in making the production of automotive parts more efficient. By optimising costs, improving quality, flexibility and environmental performance, automotive companies can not only increase competitiveness, but also make an important contribution to building a sustainable future for the sector.

Latest articles

Production efficiency

Production process mapping in the automotive industry – examples, results, implementation and potential

See more

What is Time To Market and how to reduce the value of this parameter in the automotive industry?

See more

Quality control and continuous improvement is our approach to the production of plastic components for the automotive industry

See more

Plastic injection moulding with added value, i.e. our approach to project implementation in the automotive industry

See more

Tier 1 and OEM car parts – What does the manufacturing of car components for OEM and Tier 1 look like?

See moreMicrofactories – compact plants of the future

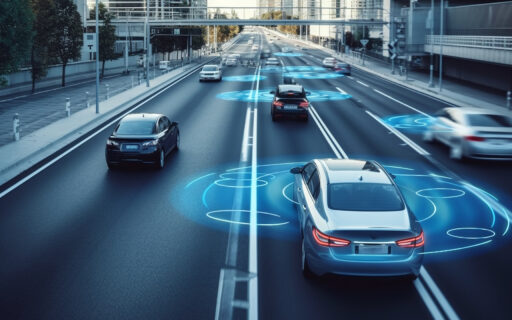

One of the most promising solutions gaining ground in the automotive industry are microfactories. These small, highly automated production facilities offer a number of advantages such as speed, flexibility and cost efficiency. Using cutting-edge technologies such as artificial intelligence (AI) and 3D printing, microfactories can adapt to changing market demands and customer needs at lightning speed.

Flexibility and scalability

Unlike traditional factories, microfactories have a high degree of flexibility, allowing production to be quickly switched to new models without incurring significant costs. Furthermore, they can operate in tandem, increasing productivity in the event of a sudden increase in demand and speeding up time-to-market.

Cost optimisation

Thanks to their smaller size and automated processes, microfactories can significantly reduce production costs compared to traditional factories. Furthermore, the construction and maintenance costs of these compact “smart factories” are significantly lower, making them accessible even to smaller players in the market.

Energy efficiency and environmental performance

The use of modern technology in microfactories also translates into greater energy efficiency and environmental performance. They can use less energy and water and use secondary and renewable materials, reducing CO2 emissions and waste production.

Industry 5.0 and factories of the future

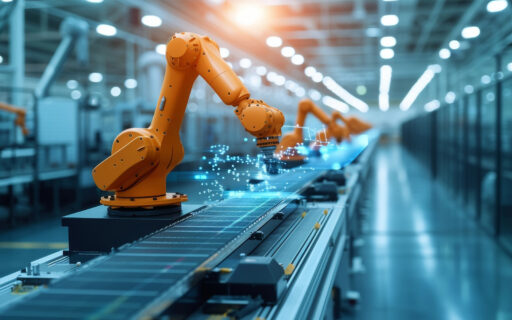

In addition to microfactories, the automotive industry is increasingly embracing the concept of Industry 5.0, which emphasises the harmonious collaboration of man and machine. By integrating advanced technologies such as robots, artificial intelligence and the Internet of Things (IoT), manufacturing efficiency and quality can be significantly improved.

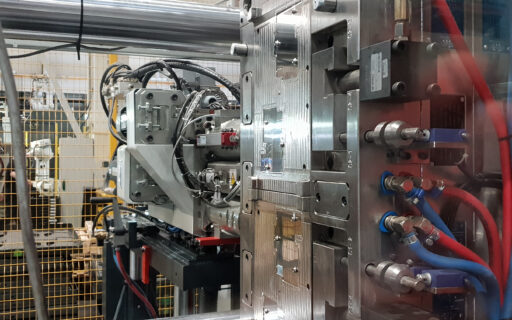

Intelligent automation

The use of robots and autonomous systems in production processes makes it possible to eliminate human error, increase precision and repeatability, and reduce costs. At the same time, thanks to the IIoT, data from machines and equipment is collected and analysed in real time, allowing processes to be optimised and more accurate decisions to be made.

Man and machine: symbiosis in action

Industry 5.0 emphasises the role of humans in the factory of the future. Employees, assisted by intelligent systems, can focus on tasks that require creativity, problem-solving and decision-making, while machines take care of routine activities. This symbiosis of man and machine leads to increased efficiency, safety and employee satisfaction.

See also: Lean manufacturing – implementing best techniques

Digital technologies and their impact on quality

Digitalisation and new technologies are playing an important role in improving production quality in the automotive industry. Solutions such as 3D scanning, artificial intelligence and machine learning are increasingly used in the area of quality control.

3D scanning in quality control

3D scanners enable fast and accurate measurements of components, allowing early detection and elimination of defects. As a result, the time and costs associated with quality control are significantly reduced, and the products that ultimately reach the customer are free of defects.

Artificial intelligence and machine learning

The use of AI and machine learning in quality control processes allows the automation of many activities, such as visual inspection or data analysis. These systems are able to detect subtle defects that the human eye might not notice, resulting in higher quality products.

Digital twins and simulations

Digital twins, or virtual models of physical objects, enable simulations and tests to be carried out while still at the design stage. This allows early detection and elimination of potential problems before they are transferred to the production line.

Find out: Key success factors, or how to increase efficiency in the automotive industry

Additive technologies in the automotive industry

3D printing technologies, also referred to as additive technologies, are becoming increasingly important in the automotive industry. They are used both in the production of components and in the development and testing processes of new solutions.

Production of spare parts

Thanks to 3D printing, manufacturers can quickly and flexibly produce spare parts on demand, eliminating the need to hold large stocks. This significantly reduces warehousing and logistics costs.

Prototyping and testing

Additive technologies enable rapid and low-cost prototyping, speeding up the development process for new products. Printed models can be tested and any corrections or modifications made iteratively.

Customisation and short runs

3D printing also makes it possible to produce bespoke components, allowing products to be tailored to individual customer preferences. These technologies work particularly well for short runs, where traditional methods could prove ineffective.

See: Time To Market optimization – how to reduce it?

Data analytics and process optimisation

Collecting and analysing data from production processes is an important part of increasing efficiency in the automotive industry. Advanced analytical tools make it possible to identify areas for improvement and make accurate decisions.

Failure monitoring and prediction

With IoT and machine condition monitoring systems, manufacturers can predict potential failures and plan preventive maintenance. This avoids unexpected downtime and associated costs.

Supply chain optimisation

Analysing data from across the supply chain enables bottlenecks to be identified and material flows to be optimised. This translates into shorter lead times and lower logistics costs.

Continuous process improvement

The use of advanced analytical tools also allows continuous monitoring and optimisation of production processes. As a result, companies can continuously improve production efficiency and quality.