The automotive industry is one of the pillars of European commerce. Nowadays, manufacturers have access to the greatest opportunities and resources of all time. Production is changing, and we need to change accordingly to keep providing customers with competitive solutions.

What is the Industrial Revolution – a short summary

Before we move on to automated factories, we must go back in time to the 18th century. This is when the first steps towards automated manufacturing were taken in England. The revolution took place in the textile sector – powerful mechanical machines were introduced and changed the way people worked. The first automated systems were nothing like modern solutions; they had very simple functions and still required people to operate them. However, in the 19th century the period of steam and electricity began, and the first steam engines – the ancestors of today's cars – were created. It was a period of new questions about the future of business and drastic social changes emerging from technological problems. It was not yet the time of robotization, but from that moment on, the human-machine relationship began to be viewed differently.

From the Third Industrial Revolution to Industry 4.0

The Third Industrial Revolution was a consequence of political changes and instability between the United States and Russia during the Cold War. During this period, the demand for goods that had previously been considered luxury items grew rapidly – fuelled by American capitalism and consumerism. Despite its infamous origins, we call it the scientific-technical revolution. As a result, it began the process of developing machine production of goods, building modern factories, and – which particularly concerns us – the use of robots in car manufacturing. The mentality of producers also changed, as they started to focus on locating production in regions with population potential. In the vicinity of renowned universities, special centres (technopoles) were created, which still contribute to development, such as Silicon Valley. The Third Revolution brought technology to its heights. However, the best technologies – namely Industry 4.0 and full robotization in many areas of production – were yet to come.

See also: Computer Aided Engineering (CAE) in automotive industry

Manufacturing automation systems in automotive factories – an extraordinary success for global industry

Let's think about how time-consuming production was in the past. We are talking about workforce and resources, but most importantly about the time it took to develop a new solution and implement it in factories. Nowadays, huge savings have been made in this respect. The whole industry is operating much more efficiently. Supply chains have been developed, and consumers are increasingly demanding new technologies. They are particularly drawn to the innovation of product-oriented solutions. One of the negative consequences resulting from the use of automation in improving production is the need to replace less-qualified workers with automated robots. This is often not a choice, but a necessity due to Industry 4.0 and its solutions. In a modern factory, the robots are responsible for production management, execution of the entire process, ensuring no mistakes are made and maintaining the highest standard of work with minimal energy consumption. This is how the most advanced production lines look today.

See also: Supply chain cost optimization and injection molding cost savings ideas

Knauf Industries and the use of automation in manufacturing

Solutions implemented in the most innovative markets can also be successfully applied in Poland. Lower Silesia, where Knauf's most modern factory is located, is characterized by an excellent research infrastructure, thanks to, for example, Wrocław University of Science and Technology. The region also has access to EPP granulate production plants (a material used for injection molding automotive parts and EPP car products) and benefits from the close proximity of automotive factories in Germany and the Czech Republic. Knauf Industries is committed to generating added value for its customers – cooperation is intended to provide mutual benefits, and the partnership approach ensures long-term success.

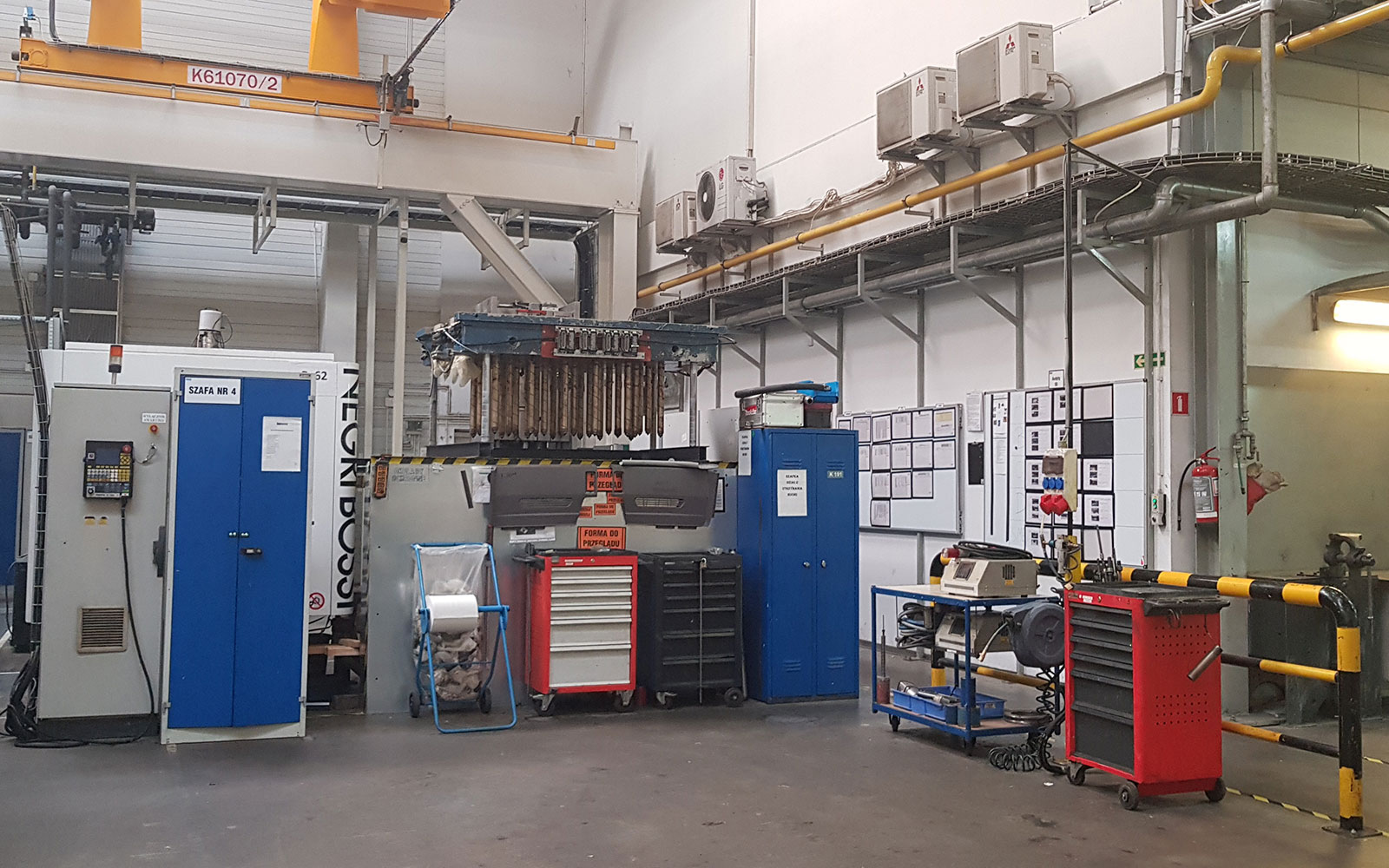

Automated car parts factory in Wrocław

Knauf Industries Wrocław is an automated factory which uses the latest market solutions. All available innovations are rapidly implemented in practice. It is worth mentioning ID Lab® – an innovation in the development of plastics processing technology for the automotive sector, based on research, observation, experimentation and cooperation with the customer. ID Lab® allows suppliers and customers to easily assess the design of their models and test them in practice. This includes efficiency improvements, pro-ecological measures (e.g. the use of environmentally friendly materials and improved energy efficiency of production) or the excellent "time to market" reduction provided by high-quality 3D solutions. Ultimately, this results in the ability to quickly adapt to the current market situation, improve the brand image, reduce costs and creatively solve any obstacles related to the adaptation of new solutions in practice.

See also: The automotive industry in Poland – what we produce and who are our customers?

Knauf Industries Wrocław is a production line ready to cooperate with the most demanding market leaders. Technology, robotization and openness to new solutions ensure that its services are of the highest quality.

See also: Production of car parts made of EPP has been launched at the factory in Wrocław