The automotive industry is still facing a long-term challenge of diminishing its impact on the environment. On the one hand it depends on a change of drive technologies and on the other hand on diminishing consumption of raw materials and greenhouse gas emission – already in the phase of manufacturing. The newest ACEA data demonstrates that the European automotive branch is on a right course.

Modern cars must fulfil growing expectations of the contemporary drivers. They are equipped with more and more advanced, intelligent safety systems and their interiors provide more comfort. In spite of this, the weight of an average car diminished thanks to application of modern, light materials. Smaller weight of a car contributes i.a. to diminishing of emission of pollutants to the atmosphere. Also dynamic development of the electric car segment fits into this pattern as they do not produce exhaust gases and thanks to simplified construction solutions they become more and more lighter. All of these changes produce substantial effects. According to the tests performed by the European Association of Vehicle Manufacturers (ACEA) almost 70% of all newly sold cars in the World emit less than 130 g CO2/km and the level of air pollution by the new cars has already dropped by 20% since 2008. And how does the production of components in the automotive supply chain look like in this respect?

An ecological car must be produced in an ecological way

Implementation of the procedures targeted to diminish a negative impact of car factories on the environment is as important as development of the ecological drive technologies and new sources of car drive power supply. It results from the ACEA report The Automobile Industry Pocket Guide 2020/2021 that the efficiency of energy use has been growing continuously. In the effect within the last 15 years energy consumption per one produced car diminished by 16.7% and emission of CO2 dropped as much as 38% in years 2005-2019. It is worth to underline that it was possible to accomplish this good result in spite of production growth by 4.3% since 2005.

Moreover, the contemporary cars are becoming more complex, which could apparently demand using of larger volumes of resources. It is influenced by continuous optimization depending on i.a. application of new, more ecological and versatile materials with multiple applications in a vehicle construction. One of them is expanded polypropylene EPP, from which Knauf Industries produces the whole gamut of car elements that find application both outside and inside of the vehicles. This material can be fully recycled, thanks to which it allows for economizing on the resources and limiting the amount of waste materials at the same time.

How do car factories save water and reduce volatile organic compounds (VOC) emissions?

Car manufacturers consistently implement the technologies allowing to diminish consumption of water necessary in the production process at their plants. Long term strategies implemented in years 2005–2019 allowed for savings in utilization of this natural resource amounting 44.8% as calculated per each manufactured car. In the majority of companies this effect has been accomplished by application of the recirculation process. For example at Knauf Industries plants water used for production of car parts is circulated in a closed system and also the condensate originating from heating and cooling systems is used. The next ecological issue, which had to be coped with by the branch was the emission of volatile organic compounds originating from e.g. solvents present in paints. Thanks to replacement of solvent paints with their solvent free, water base equivalents the car manufacturers have been able to diminish the unit emissions even up to 43.3% within the last 15 years.

Innovative light and ecological car parts

Despite much progress, which has been accomplished till now, there is still much to be done. Reduction of the impact of the automotive industry on the natural environment still remains a large global challenge. It is a complex and multi-dimensional process that requires taking into consideration of many aspects. Execution of these long term objectives depends i.a. on substitution of single elements and even complete subassemblies of a car with lighter, better optimized or made from innovative materials parts, which can be produced using less energy and natural resources.

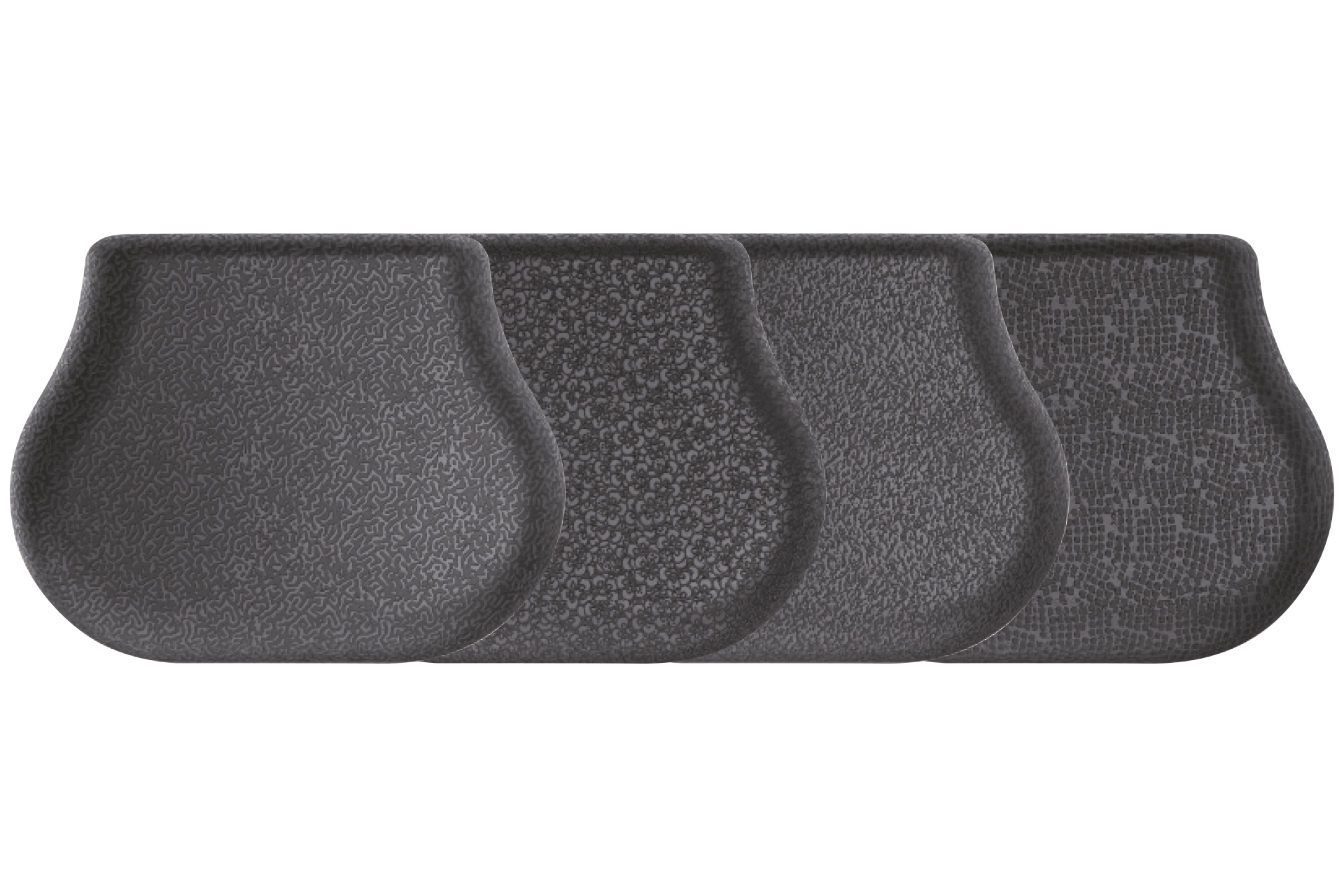

One of the significant discoveries was application of the EPP foam in production of car elements. Nowadays many different parts are made from it, comprising i.a.: door panels, fillings of seats and headrests, bases of child safety seats or boot equipment in a form of toolboxes. In electric cars it can be found also in the battery set where it is used for manufacturing of cell partitions, connection rails or even complete housings.The long list of applications of this material has been growing year after year, as it is light, durable, it makes a good vibration damper, heat insulator and provides optimal acoustics in car cabins. As it is fully recyclable, it can be used many times for manufacturing of new parts.

Now the car constructors face even more difficult task depending on searching of new applications for ecological materials, which feature minimal impact on the environment, also in the course of production. The report of ACEA demonstrates that car manufacturers are able to reach gradual yet meaningful successes, which is a good prognosis for the future.