Companies operating in the rapidly changing automotive industry must flexibly adapt to increasingly complex customer expectations, while investing in forward-looking solutions that guarantee cost optimization. One such solution is a microfactory, offering faster, cheaper and more flexible production methods.

What are microfactories?

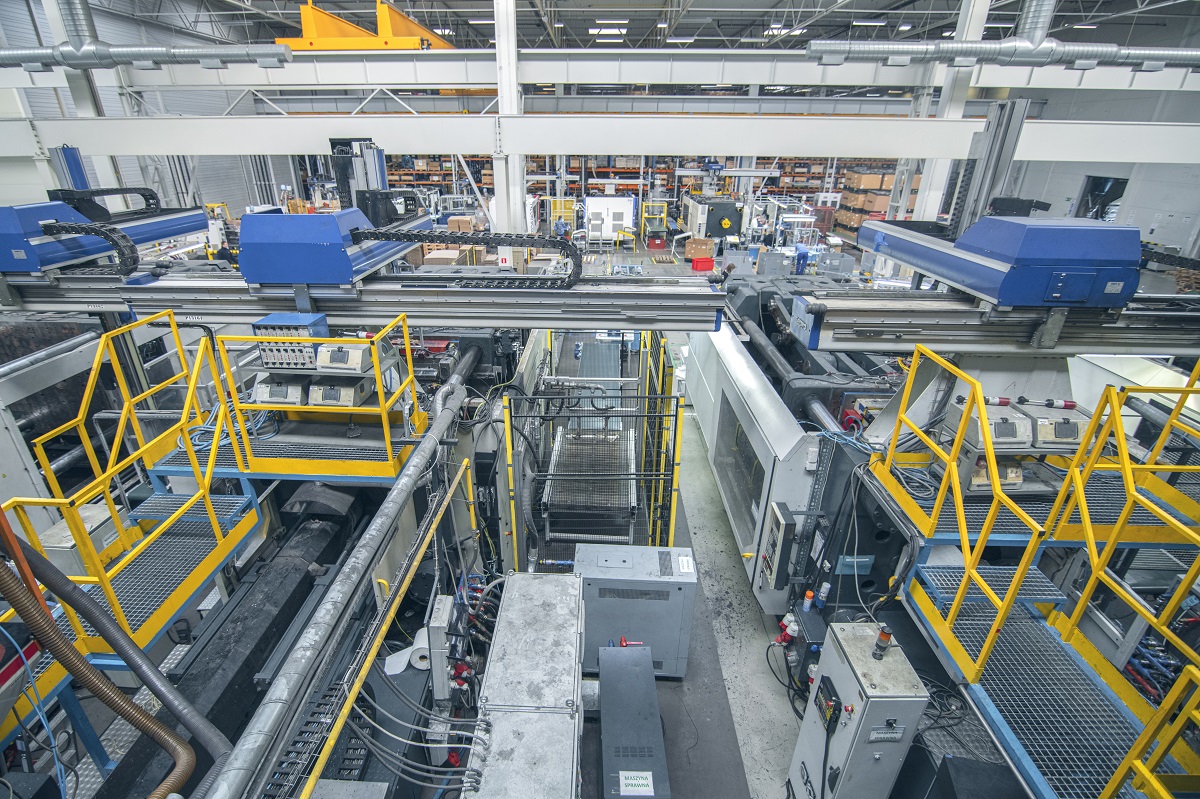

Microfactories are small, modular and highly automated production facilities that allow for fast and flexible production of small batches of products, from Tier 1 and OEM automotive parts to entire vehicles. They use cutting-edge technologies such as artificial intelligence (AI) and 3D printing in their processes, allowing them to optimize all areas of operations. Such small “smart factories” use less energy and require fewer employees to operate. Unlike traditional factories, microfactories are more adaptable and scalable.

Read more: What does the car factory of the future look like?

What can microfactories manufacture?

An area in which these small factories of the future may specialize, for example, is the production of components for smart electric vehicles. They can produce printed circuit boards, integrated circuits and other electronic components. They also often use specialized processing, such as photolithography, electro-erosion and laser cutting. Another important technological area, 3D printing is used to create precise models of various types of structures.

Benefits of modular factories

Modular factories, such as microfactories, are revolutionizing the automotive industry, as they offer many benefits, including production and operating cost savings, the ability to respond quickly to changing market trends, and lower environmental impact. Thus, they are the perfect answer to the needs of the automotive industry.

Cost-effectiveness

Because microfactories are smaller than traditional manufacturing plants, their construction and maintenance costs are even tens of times lower than those of traditional plants, allowing smaller market players to build them as well. Producing small batches of customized products does not usually require holding large inventories. In addition, thanks to their smaller size, automated processes, as well as manufacturing and design with a design thinking approach, microfactories can significantly reduce production costs.

Read more: How to increase efficiency in the automotive industry?

Low maintenance and service costs

Small factories are easier to maintain and service, which translates into lower operating costs. Fewer machines and greater process integration make mapping the production process much easier. Should any technical problems arise, they can be located and resolved more quickly. In addition, production can be shifted quickly in the event of a breakdown, minimizing downtime and associated costs.

Quick response to market demands

Microfactories adapt quickly to changing market demands and customer needs. Thanks to their high level of flexibility, these small smart factories can quickly change the type of products they manufacture without the costs associated with tuning. Importantly, they can also increase capacity when needed, operating in tandem, for example, which shortens the time-to-market and increases potential profits.

Learn more: What is Time To Market and how to reduce the value of this parameter in the automotive industry?

Energy efficiency and eco-friendliness

By using modern technology, microfactories can be more environmentally friendly, which is important in the fight against climate change. For example, they can use less energy and water, or use secondary and renewable materials. Through innovative processes, they can also emit less carbon dioxide and produce less waste compared to traditional factories. Such distributed manufacturing also provides the advantage of short delivery routes and reduced CO2 emissions associated with transportation, as such plants use local material suppliers.

Read more: How to ensure energy efficiency in the automotive industry

The future of microfactories in the automotive industry

The automotive industry stands at the threshold of a historic transformation. The regulatory package adopted in Europe assumes that only zero-emission vehicles will be sold after 2035. The electrification of cars, the use of renewable materials and all other initiatives to reduce the carbon footprint of factories are key trends today. The industry is striving to minimize its environmental impact, while advanced technology and smart factories have become a vital tool on the road to achieving sustainability goals. Microfactories provide fast and innovative answers to the challenges of today's market. Developments in technology, such as the Internet of Industrial Things (IIoT) and artificial intelligence (AI), are opening up entirely new manufacturing opportunities. Modular factories of the future can help not only increase the efficiency of the entire production process, but also solve key technological issues facing the entire automotive industry. Thus, they could bring about a breakthrough in the way we think about automotive design and production processes. Can microfactories replace traditional factories? Yes, their potential is huge, but they will not necessarily replace traditional manufacturing plants, which offer the undeniable benefits of economies of scale and high operational efficiency.

Read more: Examples, types and application of mass production