Knauf Automotive

Design Thinking

Design thinking in manufacturing and design

Design thinking is an innovative approach to design that focuses on understanding user needs and creating effective solutions. The process involves empathizing, synthesizing, generating ideas, prototyping and testing. On our site, you will find information about each stage of design thinking, practical advice, and examples of applications in various industries, including automotive. You’ll learn how technologies such as Big Data, 3D printing and lean manufacturing support the process and contribute to the creation of innovative products.

Latest articles

Design Thinking

Popular Articles

What benefits does 3D scanning provide in the area of quality control in the automotive industry?

What is design thinking?

Design Thinking is a concept you find in many industries these days. What is it and how does it affect the creation of products or services? This term refers to a modern approach to developing products and services, based on knowing and understanding the needs of target customers. This way, it is possible to prepare attractive solutions, tailored to the requirements of customers, and at the same time to reduce the risk of releasing a misguided product or service.

Phases of designs thinking

The standard approach to the Design Thinking process consists of several consecutive stages. These are, in order:

1. Understanding or empathizing

This is a key starting point for further activities, which focuses on the needs of the target audience. In this step, you should strive to understand customers’ requirements, goals and preferences – this can be done through market research or interviews, among other means. This step is combined with observation, which involves identifying the emotions, challenges and behaviors of the responders.

2. Synthesis

It is the second step of the process. Here, it is necessary to analyze the conclusions of the first step to derive the most valuable understanding of the problems and challenges.

3. Idea generation

This is the moment when creativity is key – the goal is to propose solutions that can work in later implementation. It is important to pay attention first and foremost to generating ideas, rather than a thorough evaluation of individual projects. The idea generation stage often relies on collaboration and methods such as brainstorming and mind maps.

4. Prototyping and testing

Involves creating viable models of the ideas proposed in the earlier step. This helps determine how the various solutions work in practice.

5. Implementation

It is often overlooked when discussing the Design Thinking approach – but it is worth emphasizing its importance in the role of the outcome of the entire process. In this case, it is also very important to choose a production partner who will be able to implement the developed designs.

Design thinking in business is an iterative process, meaning that the results and conclusions of the subsequent steps translate into the execution of the next steps in an iterative, continuous manner.

Examples of the application of design thinking in industry

Design Thinking projects are now being used in many industries, so you can find numerous examples of various solutions.

Regardless of the field, the process begins with a thorough understanding of the needs of the audience. This approach allows you to gain new insights into the project and take into account important elements that might be overlooked with other methods. Tools such as cost, feasibility and benefit analysis can also support the implementation of design thinking by providing valuable information during the idea generation and prototyping stages.

What other examples of the Design Thinking methodology can be found in the automotive sector? It is worth approaching the process from the needs side – currently, the requirements of both manufacturers and customers are mainly focused on increasing safety and improving the driving economy. This requires the use of suitable components with low weight and high strength, such as plastic car parts. These types of solutions are designed using modern methods, such as Design Thinking.

Technologies and processes which support automotive design thinking

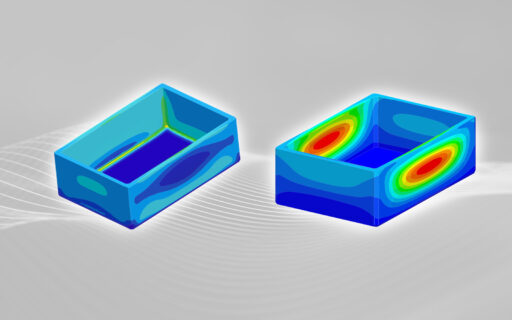

In the automotive sector, design thinking is supported by advanced technologies and processes that enable innovative and efficient solutions. Big Data and data analytics enable optimization of parts production and better understanding of customer needs, while lean manufacturing and DFM (Design for Manufacturing) are used to improve management. These are solutions that are now effectively supporting the largest companies in the automotive sector.

Design Thinking by Knauf Automotive

Design Thinking tools play an important role in many companies – Knauf Automotive is no different. Wanting to bet on professional, effective support in product development, you should take advantage of our expertise. We ensure efficient implementation of projects developed in a thoughtful manner that fit well with OEM and Tier 1 customer requirements. Contact us now to learn about innovation at Knauf Automotive.