Modern computer simulations make it possible to accurately digitally represent objects and the impacts they may be subjected to. This method finds excellent application especially in the development of products that, by virtue of their purpose, must have high strength. At Knauf Industries, it is used on a daily basis in the design and development of modern transport packaging made of foamed EPP and EPS plastics.

Why use computer-aided design?

Computer simulation involves copying objects and entire systems and studying their behavior under different conditions. In the process of simulating the widely varying loads a product may be subjected to, it is very easy to eliminate its weak spots and make adjustments. Everything is done in virtual space, which, from a design point of view, means eliminating any waste of raw materials and saving time, since changes can be made with a single click. Even very thorough modifications can be made repeatedly in the digital 3D model, and the final prototype is almost ready for production. Above all, however, numerical simulation makes it possible to implement even very bold innovations and accurately personalize customized containers and packaging without incurring additional costs.

CAD systems – how to use them effectively?

CAD is short for Computer Aided Design. Commonly, this name is used not only for Autodesk AutoCad software, but also for a whole range of different CAD, CAE (Computer Aided Engineering) and CAM (Computer Aided Manufacturing) tools, which are used by engineers, e.g. when calculating the strength parameters of a structure and then in the manufacturing process as part of Design for Manufacturing (DFM). In the past they existed as separate programs, but today the boundaries between them are blurring, as traditional CAD systems are being supplemented with CAM and CAE modules. This is how a unified design platform is created, but still each of these modules finds its specific application in a particular industry.

CAE tools in the automotive sector have made it possible to significantly speed up product development, reduce costs and, at the same time, improve safety, comfort and durability – both of automotive parts and the vehicles themselves. The same applies to packaging used in transportation. A decisive role, in this case, is played by the reliability of mapping the loads and stresses to which individual parts may be subjected in various situations during loading, transportation and storage.

2D vs 3D CAD systems for plastic returnable packaging design

There are two types of CAD design systems: 2D and 3D. The former act as a virtual drawing board, so they are often used, for example, for conceptual sketches. Much more advanced are 3D programs, where complex structures can be modeled in space, and these are more often used in the design of EPP or EPS packaging. Even more possibilities are provided by CAE-type software, which not only has the function of performing strength calculations of various types of objects, but also allows you to check their behavior under certain loads, vibrations or temperature. At Knauf Industries, we perform tests on our products under real conditions so that we can then correlate the results obtained with the computer simulation and ensure its high reliability. In addition, our specialized software allows us to accurately reproduce the shape of the parts being transported and transfer it directly to the packaging mold. If even the customer does not have a 3D model of the part in question, we can make one by mapping an already existing product using 3D scanning and reverse engineering technology.

How can you speed up the design process with CAE software?

The computer-aided design programs in use today have already achieved such a high degree of predictive capability that the design verification process is largely virtual. Analyses carried out with CAE software not only eliminate the need to prepare further prototypes, but also make it possible to find and correct design weaknesses in advance. We now have highly specialized tools with which we can subject our EPP and EPS packaging to a variety of static and dynamic mechanical tests, as well as heat transfer simulations. Under real-world conditions, this would require physical measurements that do not provide such high reliability and accuracy. The tools developed at IDlab make it possible to unequivocally determine the performance of the packaging we produce from various materials, such as EPP, EPS and thermoplastics. Reliability of reproduction of real situations is crucial in this case, as packaging used in transportation is sometimes subjected to extreme loads, so we continue to expand our database.

Examples of three-dimensional modeling and computer simulation of Knauf Industries packaging

One of the tests we use is a computer simulation of the fall of a metal part on a package from a certain height. In this way, it is possible to accurately determine the level of strength of the structure, the degree of deformation and the absorptivity of the material, and thus check how effectively it protects the contents from damage. Such dynamic simulations can also predict other scenarios, such as the fall of an empty package, a package with a specific content, and many other cases.

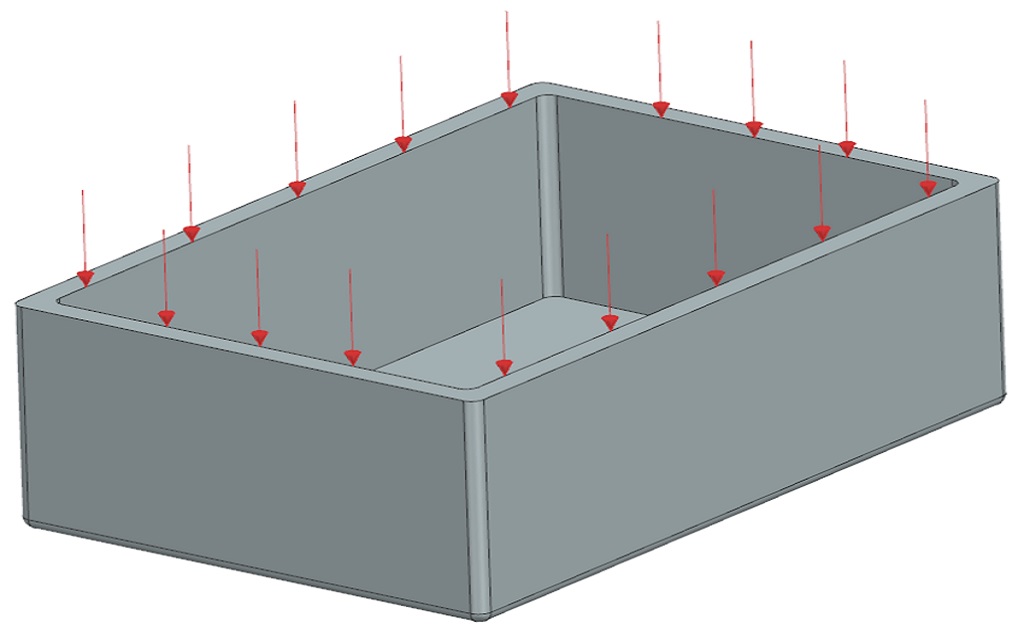

Static testing, on the other hand, involves checking, for example, how much a package will deform when another container with contents is placed on top of it. In this case, the vector of forces acting on the product is directed from top to bottom, but the forces acting on a container placed on top can also be tested. Visualization of the deformation makes it possible to determine with the customer an acceptable degree of deformation and to make possible changes involving, for example, increasing the density of the material used, wall thickness or even replacing the material. Thermal simulation of packaging is also an extremely useful study. Determining how temperatures propagate is critical, especially in the FMCG or medical industries. Such a test can involve simulating an ice cube in a package, for example.

Computer-aided packaging design – partnership with Knauf Automotive

The range of tests carried out in Knauf Industries' laboratories is much broader and can also include other areas of analysis, parts made with other materials or even finished part assemblies. We are now able to study the strength of, for example, a rear bench seat reinforced with an aluminum or steel insert, or the behavior of a car footrest or even an entire seat during an impact. Numerical simulations are currently an intensively developed area in Knauf Industries' business, as they are the optimal starting point for systematically improving our portfolio and seeking new applications for our materials and technologies in the fields of safety, energy efficiency and design. They also allow us to make meticulous feasibility and cost analyses. We would be happy to advise you individually in this regard, and invite you to cooperate with us!