Increased traffic makes it necessary for car designers to use effective soundproofing solutions. Too much noise can be tiring and cause stress, affecting the driver's concentration and therefore road safety. Another aspect is the development of car audio systems that provide excellent sound quality, as well as the growing expectations of the customers for a luxury driving experience. Modern foamed materials play an extremely important role in this respect, as they effectively reduce noise and vibration and, thanks to their cellular construction, do not increase the vehicle's kerb weight.

Noise in cars – sources and impact on comfort

Noise in a car can come from a number of different sources and its intensity depends on the vehicle design, driving speed or weather conditions. The main sources of noise are usually powertrain components. Vibrations from the engine, gearbox, radiator fans and other mechanical components are transmitted to the bodywork and from there to the cabin. In the car, the sound of the tyres rolling on the pavement is also audible, and its intensity largely depends on the speed, the quality of the road or even the structure of the tread. The phenomenon of air pumping is also worth mentioning in this context. Air trapped in the tread grooves is cyclically compressed and expanded, causing additional noise. Sounds transmitted from the wheels and suspension are often further amplified by door and wheel arch designs, which can cause resonance. Another factor is the noise of the air flowing around the bodywork, which can be annoying at high speeds. All sorts of unpleasant noises can also be caused by leaks in the vehicle's doors and windows, as well as vibrations from poorly fitted interior components such as the dashboard or upholstery.

Excessive noise can distract the driver, increasing the risk of mistakes. Prolonged exposure to unpleasant sounds causes fatigue, leading to reduced reflexes and increased stress levels. High and frequent noise pollution, e.g. during long journeys or daily commutes, can even cause elevated blood pressure, headaches and sleep problems. Appropriately designed car soundproofing systems reduce external noise and improve music reception and the quality of conversation with passengers, which contributes to a more comfortable journey.

Modern sound-absorbing technologies in the automotive industry

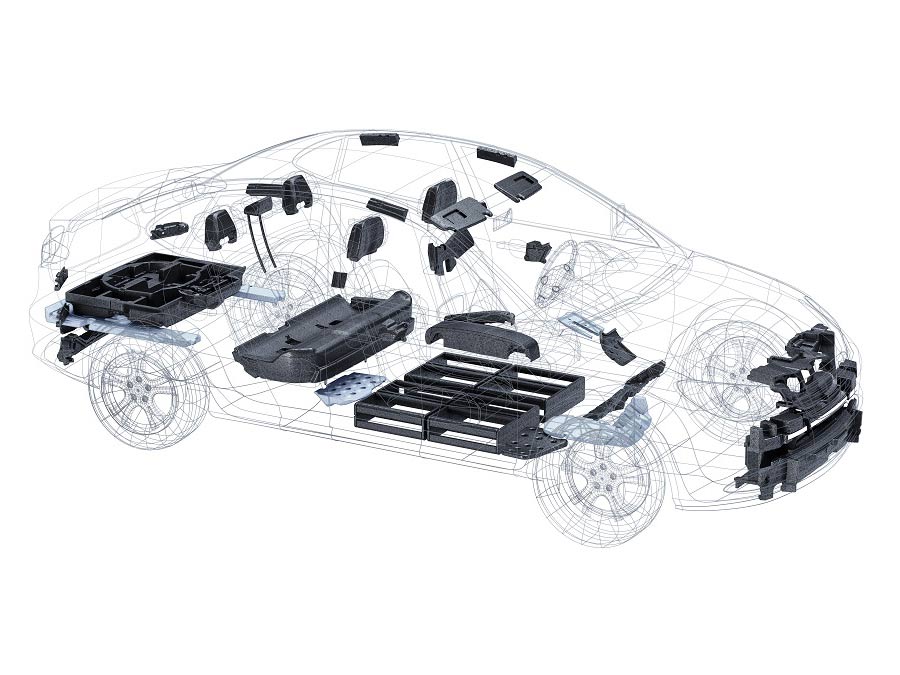

Modern acoustic technologies can be divided into passive and active. Among the former are special car soundproofing materials in the form of polyurethane, polypropylene and melamine foams that reduce reverberation and noise. Their big advantage is their minimal weight and ease of installation, while also being highly effective at absorbing high-frequency sounds. Foams with nanomaterials, in which more effective sound absorption is guaranteed by nanoparticles, are also increasingly used. In the context of sustainability, manufacturers are increasingly turning to biodegradable foam materials. In the context of passive technologies, mention can also be made of traditional bitumen and rubber mats, which are designed to dampen low-frequency vibrations and noise, but their use in cars is increasingly restricted due to their relatively heavy weight.

In the context of the interior acoustics of modern vehicles, it is impossible not to mention alternatives such as active noise reduction ANC systems. They use microphones and speakers to generate sound waves that neutralise noise. These units are strategically placed in the interior to create a surround sound effect. With advanced DSP (digital signal processing) algorithms, the sound is split into separate channels, simulating a natural space, like a live concert. Tesla, among others, is experimenting with this technology. Spatial virtualisation systems are also worth mentioning. Through the use of digital filters and artificial intelligence, the sound characteristics are adapted to the specific layout of the vehicle interior. As a result, the sound 'envelops' the passengers, improving the listening experience. Such solutions can be found in luxury models from BMW or Mercedes-Benz.

Environmental aspects of noise-absorbing materials

Sound-absorbing materials not only help to improve the soundproofing of a car, but have also become an important element of environmentally friendly strategies in the automotive industry. What is important now is both the performance of the sound insulation and the reduction of its environmental impact throughout its life cycle. There is a particularly clear emphasis on the use of renewable raw materials and materials that can be recycled or biodegraded in an environmentally friendly manner. Such sustainable solutions include mono-material EPP foams, which are 100% recyclable, or components made of biodegradable plastics used instead of traditional polyurethane foams. Recyclable materials not only stand out for having a lower carbon footprint already at the raw material acquisition stage, but also enable the implementation of the principles of a circular economy. It is worth noting that modern acoustic materials manufacturing technologies contribute to reducing the carbon footprint of a vehicle at several stages, from manufacturing to operation to disposal.

Using state-of-the-art pneumatic injection technology, it is possible to optimise water consumption, reduce the temperature of the foaming process or minimise production waste. The use of renewable energy sources on production lines further contributes to the reduction of CO2 emissions associated with material production. Lighter foam components reduce the weight of the entire vehicle, which has a direct impact on the reduction in combustion (or energy consumption in hybrid and electric vehicles) and carbon footprint during operation. On the other hand, at the end of the vehicle's life, these components can easily be reused in new cars. Recycling technologies are the ideal answer to the European Union's ever-tightening Green Deal requirements, such as the End-of-Life Vehicles Directive, which recommends that at least 25% of the plastics used in the construction of a vehicle should be recycled.

Our approach to innovation and recycling

At Knauf Automotive we consistently focus on innovation and sustainability, combining state-of-the-art acoustic material production technologies with a recycling and eco-friendly raw material approach. At the ID Lab Innovation Centre, which is a research and development space dedicated to innovation, we are looking at new solutions such as foamed plastics with the addition of recycled raw materials or based on the balance of biomass. Our experts develop solutions that not only meet the highest technical and quality requirements, but also contribute to reducing the vehicle's carbon footprint. The laboratory also focuses on the optimisation of production processes using modern tools such as numerical simulation, 3D scanners and 3D printing, allowing for faster implementation of new green solutions. ID Lab's activities also aim to tailor the properties of materials to the specific needs of customers in the automotive industry, taking into account aspects related to energy efficiency and recyclability at the end of the product life cycle. In doing so, the ID Lab Innovation Centre offers support at every stage of solution design and implementation, from material selection through prototyping to final implementation on production lines. This ensures that Knauf Automotive's customers can always benefit from technologies that not only provide effective soundproofing for the car, but also fit in with environmental protection and closed-loop economy strategies. As a result, the implemented solutions contribute to the reduction of CO2 emissions, less consumption of fossil raw materials and better life-cycle management. In addition, we have the right digital tools to calculate the environmental impact of a product. We carry out analyses based on the LCA model in accordance with EN 15804:2012+A2:2019, and are also able to provide EPD environmental declarations, which contain accurate information about the carbon footprint of a product in the production, transport, operation and disposal phases.

Benefits of improved acoustics in cars

Nowadays, optimum sound insulation in cars is no longer just a luxury accessory, but an essential element for health, travel comfort and vehicle value. Lower cabin noise reduces stress and fatigue and improves the driver's concentration, which is important especially on long journeys. In addition, the ability to use the audio systems freely ensures an enjoyable experience when using the vehicle. Advanced surround sound systems combined with the car's excellent soundproofing enable the best quality acoustic experience. In practice, this translates into a satisfying listening experience, which increases the overall quality rating of the vehicle in question. It is worth mentioning that excellent interior acoustics are an important factor for many people today when choosing a particular car model. Vehicles that offer excellent acoustic conditions are often perceived as more luxurious and technologically advanced. This translates into a higher market value for the model in question, even after time has passed.

Car soundproofing – FAQ

1) Which sound-absorbing materials are most commonly used in modern vehicles?

A variety of sound-absorbing materials are used in modern vehicles, such as acoustic foams – polyurethane, polypropylene or melamine. Increasingly, biodegradable foamed plastics are also being used, which not only reduce noise but also minimise the car's environmental impact. Further solutions include bitumen and rubber mats, as well as plastics with sound-absorbing properties used in wheel arches. Manufacturers also use special acoustic glazing technologies, particularly on premium vehicles.

2) How do sound-absorbing materials contribute to reducing noise and improving comfort in vehicles?

The use of sound-absorbing materials makes it possible to effectively dampen sounds from various sources such as the engine, tyres, wind or mechanical components. They absorb sound waves, reducing their reflection and dispersion inside the cabin. This makes the vehicle interior quieter, which improves the comfort of the journey. Bituminous mats, rubber mats and laminated glazing are effective in blocking external noise penetration into the vehicle interior. Whereas soundproofing of wheel arches i floor insulation helps to reduce the sounds generated by the tyres and road surface. The use of suitable soundproofing materials makes the interior of the vehicle more amenable to audio systems. Reducing reverberation and echo makes the sound cleaner and clearer.

3) What are the benefits to car performance of using sound-absorbing materials in the manufacture of automotive components?

Modern soundproofing materials are becoming lighter and lighter, so they do not add extra weight to the car. A lighter vehicle uses less fuel or electricity, resulting in greater efficiency and lower emissions. In addition, sound-absorbing materials used in wheel arches, underbody and the soundproofing of car doors help to reduce aerodynamic noise, which contributes to greater driving comfort at higher speeds. Silencing the engine compartment reduces resonance and vibration, which can also improve the efficiency of the drive unit. Reducing noise also increases the likelihood of detecting possible faults, as any changes in the vehicle's operation can be picked up more easily.

4) What innovative acoustic technologies can support increased efficiency and comfort in modern vehicles?

Modern acoustic technologies play a key role in improving travel comfort and vehicle efficiency. ANC systems, for example, use microphones to monitor noise in the cabin and generate counter-phase sound waves that neutralise unwanted sounds. This technology is particularly effective in eliminating engine, tyre and wind noise, which significantly improves journey comfort. Modern acoustic foams such as EPP, for example, are designed to effectively absorb sound while reducing environmental impact. The use of fully recyclable materials reduces the vehicle's carbon footprint. Advanced audio systems, such as Dolby Atmos and 3D sound, provide a realistic acoustic experience, improving the quality of music and communication in the cabin. Thanks to the precise positioning of the speakers, passengers can enjoy immersive sound without interference.

5) How does the introduction of sound-absorbing materials affect the durability and reliability of automotive components?

Sound-absorbing materials not only improve driving comfort, but also contribute to the durability and reliability of the components in the car. Soundproofing materials such as EPP foams reduce vibrations transmitted through the engine, suspension and other components. This reduces the risk of micro-cracking and premature component wear. Some acoustic materials, such as acoustic plastic wheel arches, protect vehicle components from moisture, road salt and chemicals, extending their life. Well-designed soundproofing materials improve airflow around the vehicle, which reduces aerodynamic noise and improves vehicle stability at higher speeds. Some soundproofing solutions also act as thermal insulation at the same time, helping to maintain the optimum operating temperature of components, reducing the risk of overheating. By reducing noise, vibration and protecting against external factors, automotive components wear out more slowly, resulting in lower operating costs and a longer vehicle life.