Optimizing manufacturing processes is an important activity for every sector. New technologies are also being applied in the automotive industry. This is helped, among other things, by the ongoing analysis of data related to the production of automotive components. Big data in manufacturing is an extremely useful tool that makes it possible not only to increase profits by streamlining processes, but also to evaluate prototypes of new components.

See also: Cost-benefit and feasibility analysis in the automotive sector

Big data in manufacturing

Big data analytics in manufacturing involves searching for, retrieving, collecting and interpreting data that can contribute to meeting required objectives. An optimized data collection and analysis system is currently essential for creating the right manufacturing conditions. Among other things, such processes make it possible to find potential manufacturing errors very quickly and to start correcting them right away. The possibilities of manufacturing data analytics are enormous and are becoming a real strength of plants that use this type of technology. The use of big data in manufacturing provides a competitive advantage primarily due to the fact that this approach allows for an extremely efficient and deep analysis of potential process improvements within a given company or plant.

See also: What does the Fourth Industrial Revolution look like in the automotive industry?

The technology of collecting data on relevant processes is used in many different industries. For years, companies in the financial sector or website owners, among others, have been taking advantage of its possibilities. Big data in manufacturing is also becoming an increasingly popular solution due to its potential to minimize waste and thus maximize profits.

See also: What is Lean SCM? Automotive Lean Supply Chain benefits you should know

An important issue in the context of big data analytics is knowing how to collect data in such a way that it is able to deliver the greatest value. The first step is to identify the relevant sources of information. Data on the manufacturing industry is collected on an ongoing basis from all machines that are part of manufacturing processes. Next, the data needs to be segmented – the manufacturing of automotive components consists of many stages and is quite a complex process, so it is necessary to carefully check and select the information collected. Another important aspect is data storage and interpretation. Statistical analysis of large sets of information is a key step for any entity using techniques related to big data – it is the only way to effectively draw conclusions from the collected data.

How does big data analytics translate into increased manufacturing efficiency?

Once the data generated by the operation of production lines has been collected, it is possible to realistically assess the speed and quality of the machines, as well as the efficiency of the people who operate them. This, in turn, makes it possible for big data in automotive manufacturing to introduce changes at various stages of production processes to improve the delivery of automotive components. Analysing manufacturing data also makes it possible to abandon solutions that do not work in practice and lead to lower productivity. It is also an opportunity to adjust the structure of the organization after determining how employees perform in certain positions. Big data analytics techniques can therefore affect many aspects of the work of suppliers of different types of parts – both in terms of the performance of the equipment and the people involved in the processes in question.

See also: How does Knauf Automotive produce auto parts for OEM and Tier 1?

Big data in manufacturing allows you to assess when processes are most efficient

Data collection also makes it possible to assess the times and conditions under which manufacturing in a plant is most efficient. This is an issue that depends on many sensitive factors – it is often the case that specific days and hours are associated with better results on the production line. This, in turn, directly translates into the ability to describe the ideal conditions for the production of individual components.

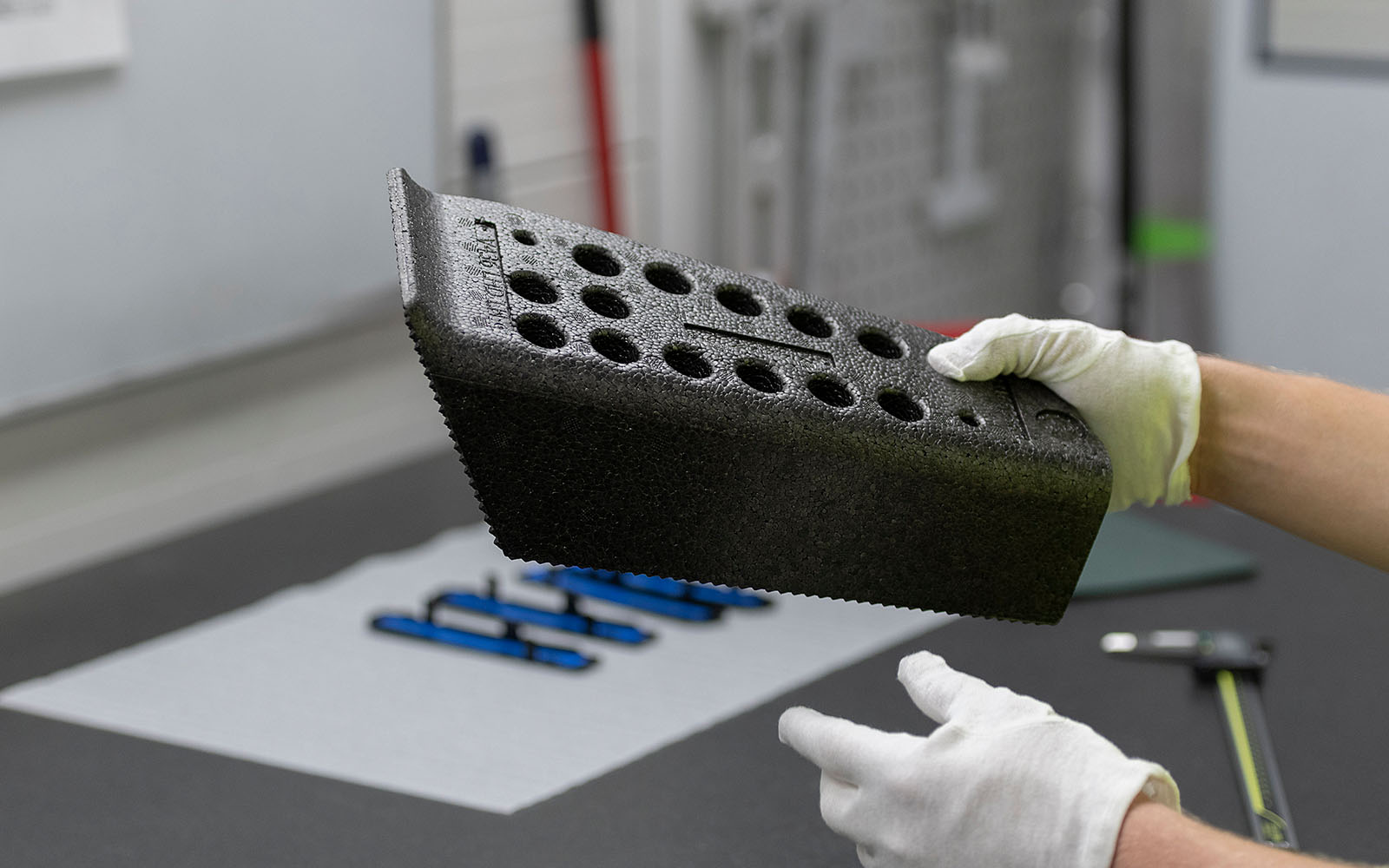

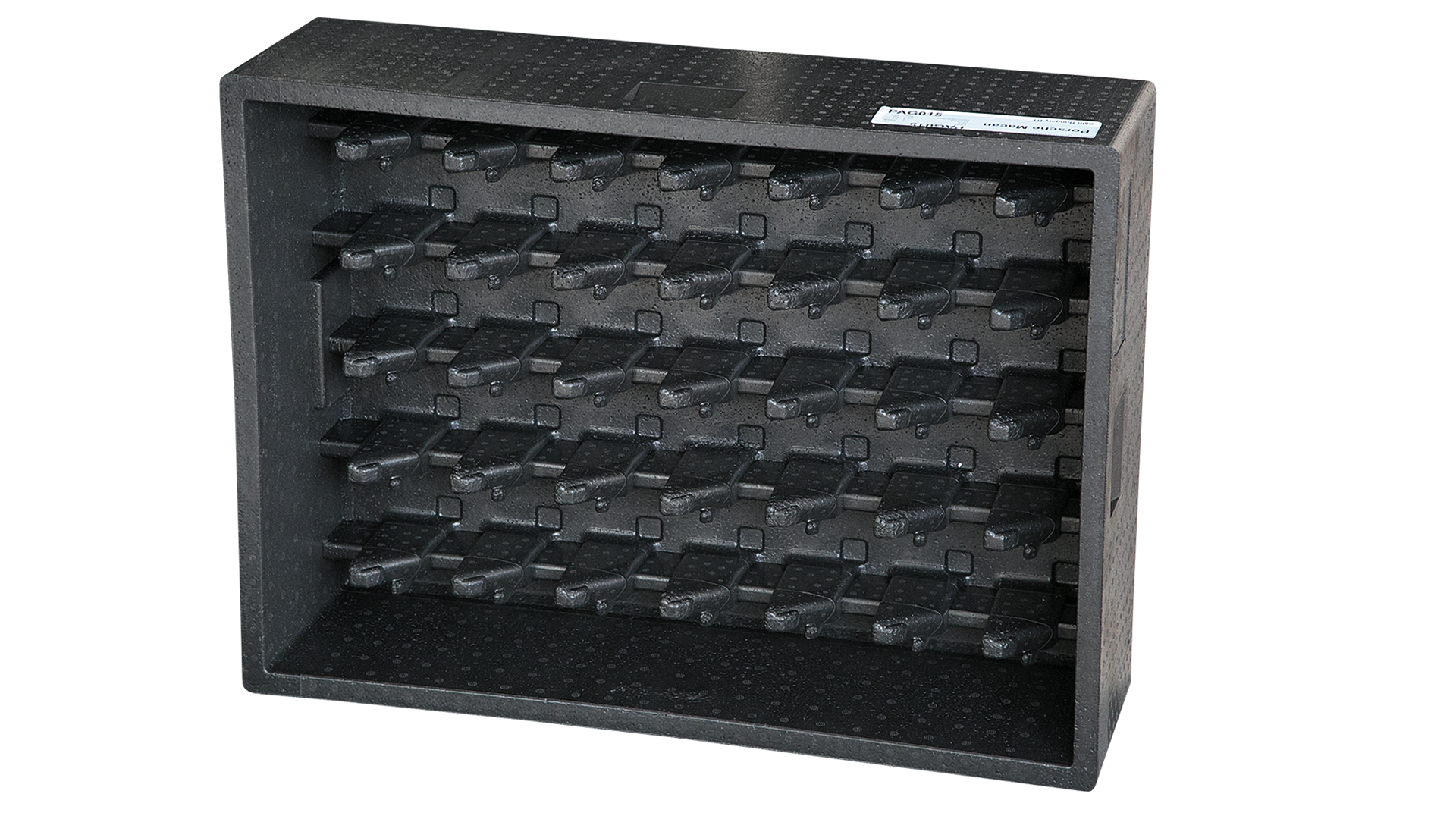

Quality assessment of prototypes – research undertaken in the area of big data in industry

These are just some of the situations that involve possible improvements to manufacturing processes using data analytics. Big data also makes it possible to comprehensively evaluate each prototype of a component before bringing it to market. The manufacturing statistics of a given part allow us to assess the time and financial resources required to produce it on a larger scale. This makes it possible to adjust the design at the prototype stage, which translates into significantly reduced waste in the future. Another area where the potential of big data can be seen is in negotiations with potential business partners – specific data can be used to present very convincing arguments.

See also: DFM – Design for Manufacturing in the automotive industry. Advantages, added value and costs

The use of big data in the manufacturing industry of the future

Big data is a relatively young field, which has already managed to make a significant impact on manufacturing processes in the automotive industry. As computing performance improves and new solutions are developed, these techniques will be used even more widely in the future. Current trends in data collection will play an important role in the use of data analysis over the next decades. Information is now becoming one of the most important resources at our disposal, practically a separate “currency.” It is definitely worth devoting some resources to determining how to use it in an optimal way, drawing on the full potential of big data analytics in manufacturing.

See also: Advanced 3D technology: 3D printing, analysis and rapid prototyping in the automotive industry

Innovative manufacturing processes using big data

More and more companies in the automotive sector are making great use of data to improve their manufacturing processes. Big data analysis is used, among others, by Knauf Industries, a leader in modern automotive manufacturing solutions. The processing and interpretation of data provides a powerful tool to increase the efficiency of manufacturing processes on a previously unknown scale.

See more about our expertise in plastic processing and do not hesitate contact with us.