The development of the lithium-ion cell market is not slowing down. Quite the opposite – every year more and more companies specializing in the production of electric car batteries are being established. According to preliminary estimates, by 2040 around 70% of all personal vehicles will be powered by electricity – battery manufacturers will play an important role in this transformation.

What companies make electric car batteries?

Growing demand for lithium-ion batteries provides companies producing them with a real opportunity for intensive development. Currently, the biggest players in this market are first of all China, Japan, Korea and USA – these are the countries where top companies producing batteries for electric cars, such as Panasonic, LG Chem, Samsung, Beijing Pride Power, SB LiMotive or Tesla have their headquarters. The comprehensive list is much longer and more corporations are constantly joining it. It is also worth paying attention to additional elements that support the operation of the battery or protect this key component – these include parts related to insulation or cushioning.

Read also: Car battery insulation systems and shock management solutions manufactured by Knauf Automotive

The role of the European Union in the manufacturing of electric car batteries

According to forecasts, the demand for EV batteries may increase up to five times in the next 20 years. The European Union intensively supports the development of the electric car market and actively promotes this type of solution – for this reason, in 2017, the European Commission launched the European Battery Alliance. Just one year after its launch, significant progress has already been made in the field of battery production in Europe. Knauf Industries joined the EBA community in 2020 as one of the battery supply chain participants manufacturing plastic components for battery packs.

Read also: New trends and developments in global automotive industry versus COVID-19

In Europe, the Swedish company Northvolt is the leading battery manufacturer. An important competitor for the Asian market is the Automotive Cell Company (ACC), a joint venture between Saft/Total and PSA/Opel.

In the context of EV battery manufacturers, Polish companies are also worth mentioning. Despite the fact that there is no factory producing this type of cars in Poland yet, large projects related to components for battery production are already being implemented. There are plenty of Polish branches of global companies as well. One example is LG Solution Wrocław – currently the largest European manufacturer of lithium-ion batteries for the automotive industry.

Read also: Production of car parts made of EPP has been launched at the factory in Wrocław

Cost of manufacturing electric car batteries

The cost of an electric car battery now accounts for more than 30 percent of the total value of the vehicle. The reason for this is the high price of the rare-earth elements that are required to make the battery – lithium, nickel, cobalt and magnesium, among others. Expenses associated with the extraction of these elements account for more than half of the cost of the entire battery. In addition, the price of EV batteries is also affected by the need to use additional elements in the construction, which are designed to prevent electrical breakdown and protect sensitive battery components.

Tesla’s LFP batteries – sample of innovative EV company

Growing raw material prices are motivating some companies to look for alternatives – one example is Tesla, which announced in 2020 that it plans to switch to cheaper lithium-iron-phosphate batteries. However, this will not apply to all vehicle models offered by the company. Contemporary Amperex Technology Co. – the world's largest battery manufacturer – is working on improving the performance of the new components. Meanwhile, production methods are being developed with startups such as Our Next Energy of Novi, Michigan. Elon Musk recently announced that LFP batteries will be used in all lower-cost models, while nickel and manganese-based batteries will be used in cars focused on long-range performance.

Read also: Innovative solid-state batteries in electric cars

Battery alone is not everything – additional components are also important

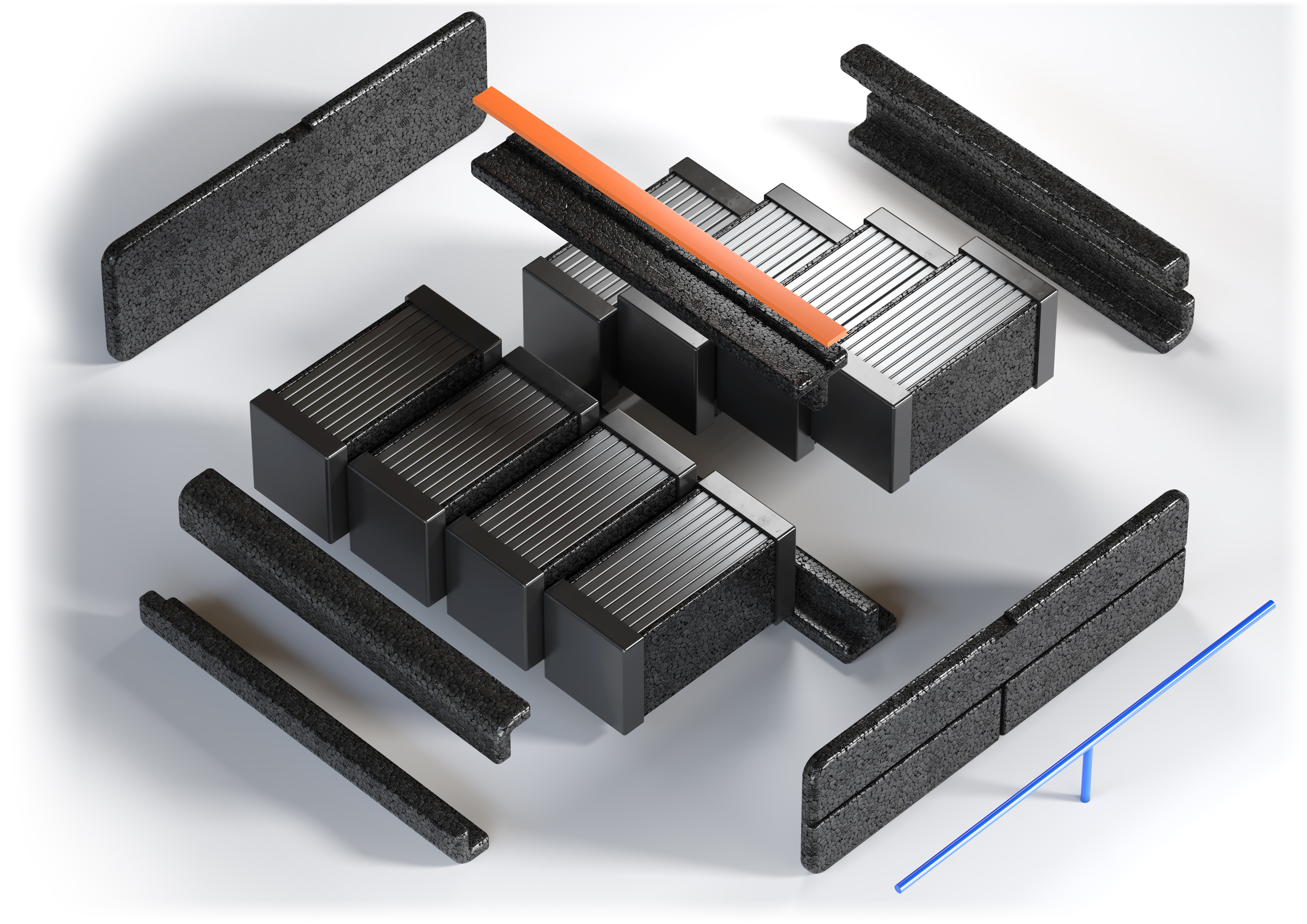

Like other components of the car, the EV battery needs to be properly protected. Road traffic is quite a demanding environment for lithium-ion batteries – they are exposed to all sorts of impacts and quite intensive use while driving. As a result, their capacity and performance can gradually decrease, which translates into a lower range of the car. It is therefore important to use components such as cell separators, which absorb shocks, or durable insulating elements.

Battery protection and its lifetime

Apart from the manufacturing itself, EV battery companies place great importance on developing new technologies to increase battery life and durability. Given the high production costs of batteries, it is important that they are efficient and exhibit reduced levels of deterioration even after long periods of use. One of the decisive factors in the life of a battery is how it is used – however, it is equally important that it is properly protected. At Knauf Automotive we offer solutions in this area, specializing, among other things, in systems for insulating car batteries and components that protect the battery against shocks.

Knauf Automotive relies on the lightweight and flexible foamed polypropylene (EPP) material as well as different specialty foams for its battery pack insulation components. It is used to manufacture complete battery insulation kits, which are not only lightweight, but also resistant to a variety of mechanical damage. Moreover, EPP foam has thermal insulating properties, which prevent the transmission of high temperatures between individual cells. It is also fire and heat resistant – these are other features that are important in the context of electric car batteries.