The new draft regulation prepared by the European Commission provides for a ban on the sale of vehicles with combustion engines from 2035. If it is adopted, in 14 years all new cars in Europe will be completely zero-emission, electric or hydrogen powered. This also means that the development of green automotive technologies and the expansion of the infrastructure for charging such vehicles will have to significantly accelerate.

The automotive industry has been preparing for years for the very restrictive limitations resulting from the environmental strategy adopted by the European Union. The objective for 2030 is to reduce CO2 emissions by at least 55% compared to 1990, and ultimately for the European Union to achieve climate neutrality in 2050. The automotive sector is not only producing combustion engine cars that meet increasingly stringent emission requirements, but is also increasing the proportion of electric and hybrid cars.

At the same time, fewer diesel cars are being produced due to the limits. Some manufacturers declare that they will no longer develop the next generation of diesels or even stop their production in the near future. What is more, cars with diesel engine have been banned from entering certain zones in Europe for some time now. All this translates into steadily falling sales of diesel cars and may mean their withdrawal from the offer of some manufacturers even before 2035.

Diesel or petrol, or perhaps alternative fuel?

The latest report published by the European Automobile Manufacturers' Association ACEA shows that in the second quarter of 2021 the share of diesel cars in total sales amounted to only 20%. The best performers in this respect are cars with petrol engines with 42%, followed by cars with alternative drive systems, i.e. various types of electric cars, which now constitute over 32% of the market. This means a gradual replacement of diesel engines by green technologies. This is not only the result of growing environmental awareness, but also of practical considerations.

In many European cities you can drive a diesel car only if it is new and has a special low-emission sticker. However, in some places, entry of such vehicles is completely prohibited, even if they meet the highest standards of emissions of particulates and nitrogen oxides Euro 6. The so-called blue zones have already been established, among others in Berlin and Paris. Moreover, by 2025 it will no longer be possible to enter the centre of Paris, Madrid or Athens. Further restrictions for diesels result from their high harmfulness to health and the environment, which particularly affects older generations of vehicles. A study by the ADAC organisation carried out a few years ago on 38 diesel cars showed that some exceeded the standards for nitrogen oxide emissions by up to 900%. These compounds can cause heart and respiratory diseases as well as cancer.

Electric and hydrogen cars instead of diesel

If the new draft regulation is approved by all EU countries, not only will diesel cars be definitively withdrawn from sale across Europe in 2035, but also petrol and even hybrid cars. This means that work on zero-emission technologies – batteries for electric cars and hydrogen cells – will have to be accelerated. Furthermore, it will be necessary to expand the network of charging points for alternative propulsion vehicles.

The new draft regulation imposes on Member States the obligation to provide charge stations every 60 km along motorways and hydrogen charging points every 150 km at the most, as well as to increase the density of this type of infrastructure in towns. It will also be necessary to extend the ranges of electric cars, which involves increasing their battery capacity on the one hand, and reducing their own weight, which will reduce their energy demand, on the other. New, lighter designs, however, require the use of innovative, ultra-light materials.

EPP expanded polypropylene 'powers' the green revolution

For some time now, car manufacturers have been looking for new production technologies and materials, which will make it possible to “slim down” the structure of vehicles, while maintaining the best possible parameters related to strength and, consequently, safety. In this context, the key role is played by modern EPP foams, which are widely used in the production of car body elements – both inside and outside.

Pressure-moulded EPP car parts are characterised by high resistance to mechanical damage and do not disintegrate into pieces, while also displaying the ability to return to their previous shape. Thanks to that, they are perfect as passive safety elements, as fillings for bumpers, headrests or rear seats. At the same time, they have excellent acoustic and thermal insulation properties, which means that they are used as headliners or door and floor fillings, effectively protecting the car interior against unfavourable weather conditions and noise.

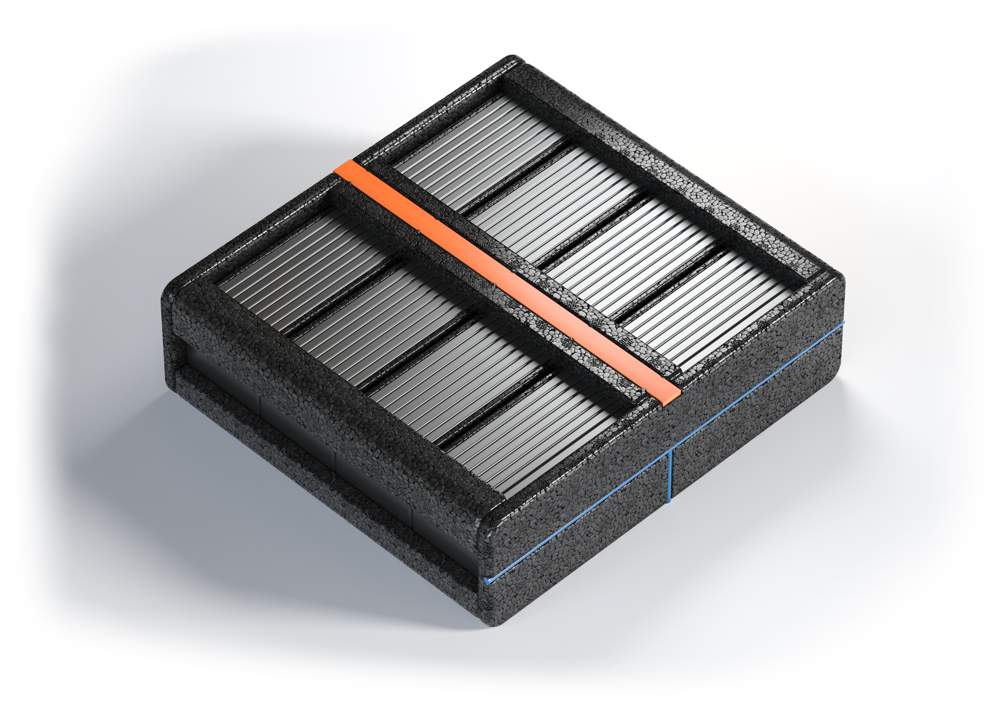

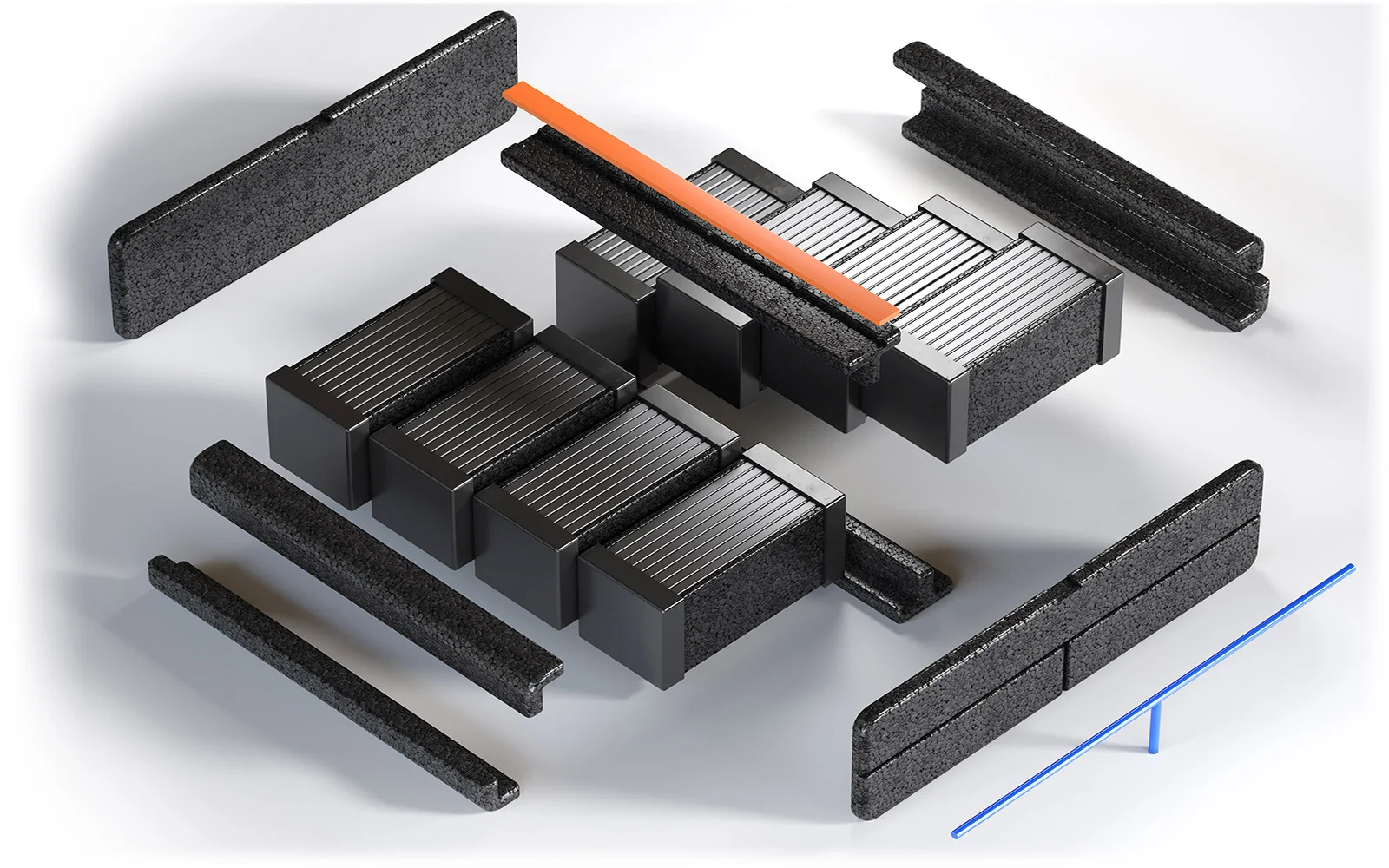

Recently, they have also been used to manufacture components for electric car batteries, where they act as insulators and fasteners. Their significant advantage over traditional plastics is their minimal weight and recyclability, which also meets the strict requirements imposed on car manufacturers by the European Union. It is also the optimum choice from an economic point of view – the method of pneumatic moulding of car parts in combination with the latest modelling technologies allows for easy start-up of mass production of even the most complex designs.