Actions of the European Union are consistently aimed at further improvement of road traffic safety, which is to be accomplished e.g. by regulations making use of definite active safety systems mandatory in all new cars. Experts point out that electric cars will also exert positive influence on reduction of the number of accidents.

As it is demonstrated by the statistics, the roads in the area of the European Union are currently the safest roads in the world. Per one million of its inhabitants there are only 49 fatalities in average when the world average figure amounts 174 fatalities per one million of the inhabitants of the globe. Within the two last decades the number of road accidents in Europe has been decreased by half, however, year to year this tendency has been slowed down. Moreover, the traffic accidents still constitute the largest percentage of all the fatal incidents, reaching even up to 46%. The largest number of such incidents occurs on intercity roads, even up to 55%. The second place is occupied by accidents in urban areas – 37%. Motor ways are the safest, where only 8% of such incidents occur. New safety systems in cars and regulations are continuously implemented, which in the opinion of their makers respond better to current social and demographic changes. They comprise aging of the society, appearance of new sources of distraction in the form of smartphones or navigation systems and also the increasing number of cyclists and pedestrians.

Not only new regulations concerning safety, but also electric cars

In 2019 regulations requesting application of as many as 30 new life saving technologies in all the new cars in the European Union were implemented, such as e.g. intelligent speed adjustment, warning against loss of concentration or detection of objects while driving back. Their task is to support a driver in safe driving a vehicle and react when there occur any risk of a collision. Experts, however, point out that the second important factor improving traffic safety will be a growing number of users of electric cars, which will transfer to the change of driving style to more economic and peaceful, especially on the intercity roads. It is influenced both by sheer utility aspects as well as the construction ones. Firstly the recharging infrastructure is poorly developed. It forces the drivers to learn new habits. Slower and smother driving avoiding sudden breaking and acceleration allows to extend the range of an electric car. It favours observance of permissible speed limits and easier legibility of driving for other road users. The average recharging time of a car is also significant. It can be even over 40 minutes, which in case of a longer journey makes a good occasion for the driver to take rest. In addition planning of a journey with an electric car imposes planning of the route so as recharging carports were on the way. First of all, though, the construction of an electric car favours increasing of the safety level.

How does the construction of an electric car influence the safety?

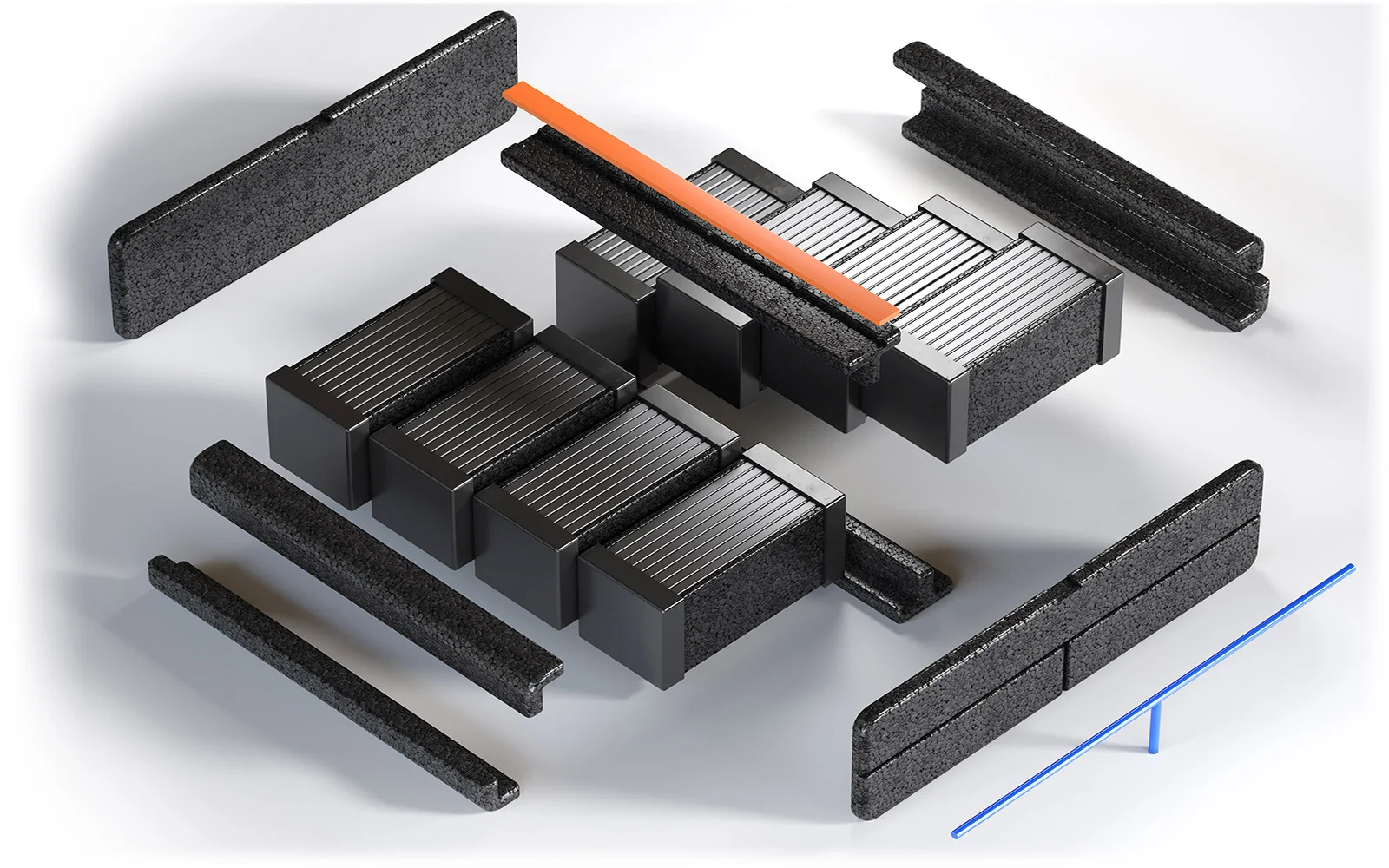

According to the automotive branch experts the electric cars protect against the results of an accident not only due to the fact of featuring the most modern technologies of the active safety systems, which are required by the European Union. The sturdy construction of an electric car considers a strengthened frame, which is objected to protect both batteries as well as passengers against side impacts. A battery module located in the floor constitutes an additional barrier suppressing forces appearing at the moment of a crash, and the lowered centre of gravity prevents turning the car upside down. It is worth mentioning that robust battery set casings are more frequently made form special expanded polypropylene (EPP), which is not only very strong but very light as well.

Parts form the EPP for electric cars as an element of passive safety system

Elements produced in the factories of Knauf Industries from the expanded polypropylene (EPP) for car battery sets perfectly suppress vibrations and impacts and do not durably deform. Thanks to their properties of thermal insulation they care for maintaining stable temperature of cell operation, thus extending their durability.

The modern EPP foams are used in the interiors of the newest class cars, also as a filling material for headrests, seats, roof lining and side panels as they are impact resistant and do not disintegrate. All of this makes that they constitute excellent completion of the passive safety systems. Moreover, the processing technologies used at the factories of Knauf Industries allow for precise balancing of the parameters of the parts made from expanded polypropylene (EPP), such as density, weight and mechanical strength. It creates completely new possibilities in the field of designing elements for electric cars.