Car batteries used in electric vehicles have a certain capacity, which gradually decreases with successive charging cycles. As a result, the range of the car also decreases. If the battery is used for several years, it may be necessary to replace the battery – you should know how to approach this task.

When should the batteries in an electric car be replaced?

One of the most important parameters describing car batteries (batteries) is capacity, or the ability of the cell to store an electrical charge. It is expressed in ampere-hours or kilowatt-hours, which describes the ability to supply power at a given amperage or power for a designated period of time. When it becomes insufficient for the proper operation of the car's electrical systems, the battery should be replaced with a new one.

An electric battery for a car – whether internal combustion or electric-powered – is a type of galvanic cell that has the ability to be recharged and used repeatedly. This is possible due to the reversible chemical reactions that take place in the electrolyte (a substance capable of conducting electricity) and at its contact with the electrodes. The operating characteristics of any battery can be divided into two basic parts. The first is charging, during which the battery is a receiver of electrical energy – in turn, this energy is converted into chemical energy. The second part is the extraction of energy from the battery, which occurs while the car is being driven. The battery then becomes a source of electricity through the reverse process, which is the conversion of chemical energy into electrical energy.

How often should a car battery be replaced?

The lithium-ion car battery is the most common solution offered by electric car manufacturers. Batteries of this type allow to drive a relatively large number of kilometers compared to other available technologies. This is primarily due to the high-energy density, which makes it possible to store a sizable charge per kilogram of a cell. However, the exact lifespan of electric batteries is difficult to determine – much in this regard depends on the manner and intensity of use of the vehicle in question, as well as the number of charging cycles. Most often, however, it is a period of 5-6 years. It is worth remembering that in most cases, the replacement of the battery is subject to warranty, if its capacity falls below 60-70% of the original value within a certain period of time.

Car battery replacement step by step

While replacing the battery in most slightly older internal combustion cars is a task you can do yourself, newer models and electric vehicles usually do not allow for this option. This is largely due to the much higher level of sophistication of the various systems, and in some cases the need for specialized equipment. For this reason, in many situations the best way to replace the battery will be to simply entrust this task to a specialist.

The entire process begins with placing the car in a safe place – that is, on a flat surface, away from any sources of fire. Next, the handbrake must be applied, the ignition must be turned off and the keys removed from the ignition. It is worth remembering that for different car models, disconnecting individual devices from the power supply can result in electronic problems. Disconnecting the battery itself starts with unscrewing the clamp from the negative terminal and then the positive terminal. After that, all the battery's protections must be removed and the battery must be removed from the vehicle. When it comes to installing a new battery, the order is reversed – the positive terminal is installed first, followed by the negative terminal. It is also important to tighten the clamps firmly enough to keep the battery stable.

Can the time between battery replacements be extended?

In recent years, there has been more and more talk about solid-state batteries, which could eliminate the commonly used lithium-ion batteries in the near future. Solid-state batteries are characterized by the presence of a solid electrolyte instead of a liquid.

The use of this type of battery effectively solves the problem of low capacity, which translates into a short vehicle range – it is also a way to reduce the degradation of the cell with multiple charging cycles.

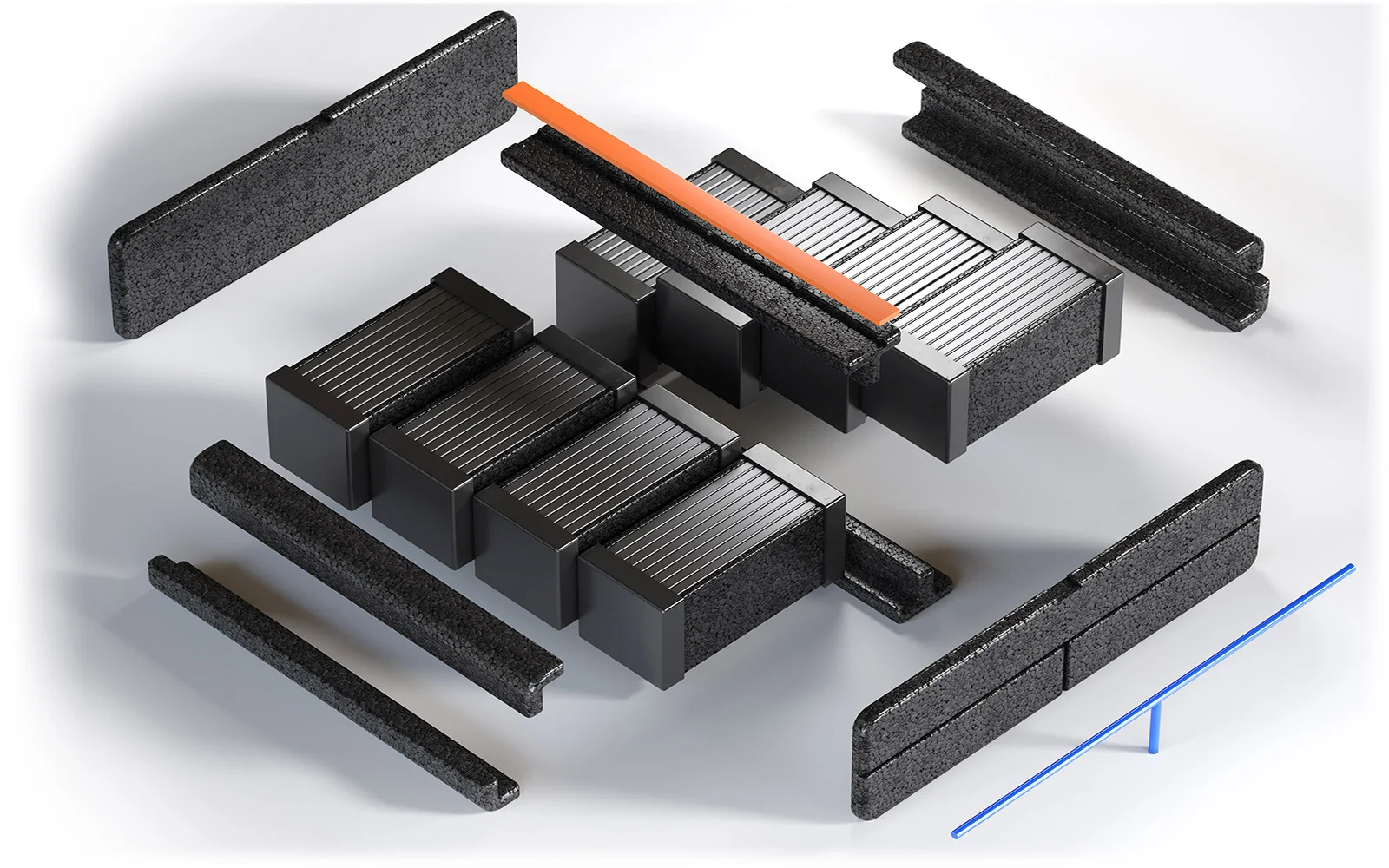

In order for a solid-state battery to provide optimal performance, it is necessary to support this technology with other solutions, not necessarily directly related to the cells themselves. We are primarily talking about the right automotive parts. In the automotive sector, EPP foam battery components and shock protection components are playing an increasingly important role. At present, they are commonly used in lithium-ion batteries, but they can also be adapted to work with solid-state batteries without too much trouble.

Car battery kit from Knauf Automotive

Adapting to the design challenges in the production of automobiles requires the right support. As Knauf Automotive, we can offer years of experience to support major electric and hybrid vehicle manufacturers with innovative designs. We are a designer and manufacturer of foamed plastic components with unique properties. Our solutions include such proposals as an car battery pack that provides side shock absorption, excellent impact absorption and thermal insulation. Feel free to contact us to learn more about our solutions and services for the automotive sector.