DFM ROLE AND DEFINITION. HOW TO DESIGN A PRODUCT FOR MANUFACTURING?

There are many mechanisms to streamline and facilitate production processes. However, few of them work as effectively as DFM. Proper technical analysis is the key to reducing production costs and creating thoughtful, efficient solutions, as well as reducing the environmental impact of operations.

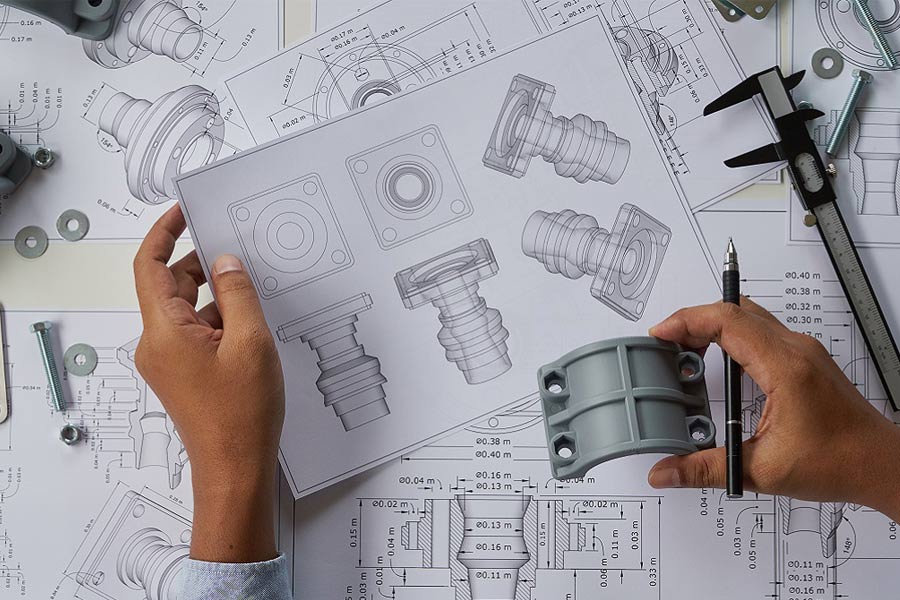

DFM, or Design for Manufacturing, is a term sometimes translated as design for manufacturing or design under manufacturing. It is a set of processes that are part of the technical analysis of a manufactured product. Complex DFx methodologies, including DFM and DFMA (Design for Manufacture and Assembly), are used at the stage of analyzing the technological feasibility of a design, which consists of a comprehensive study of various parameters aimed at verifying that a given design meets the real needs of the structure.

Design for manufacturing in the area of injection molded parts, as well as foamed plastics, includes tasks such as rheological analysis, kinematic analysis and heat balance analysis. The component is examined from many angles using professional software, usually CAD systems. Simulations of real-world conditions provide a considerable amount of data, and their appropriate use leads to an even better understanding of the features of the part and the potential for improving its production. However, this is not a simple process – so you need to properly prepare your technological background and have access to a considerable body of knowledge.

EFFICIENT DFM PROCESS: MULTIDISCIPLINARY APPROACH

DFM engineering requires, first of all, a great deal of knowledge, which, in the case of vehicle-mounted components, combines the physics aspect of driving with the characteristics of individual materials and the behavior of the parts in question under specific conditions. Conducting simulations to illustrate in a complete way the characteristics of a given product is a complex process. Correctly interpreting the results requires experts who have an excellent understanding of the issues involved in manufacturing automotive parts.

A considerable amount of data is required to design a component in the right way. Experts from different fields can exchange their experiences within the DFM to select the best manufacturing strategy for a component. With the right flow of data between specialists who deal with materials science, physics, chemistry and manufacturing itself, it is possible to delineate DFM strategies and designs to bring a product to market.

ADVANTAGES OF DFM: ADDED VALUE IN THE AUTOMOTIVE SECTOR

DFM is often treated as a process to make the production of a component much cheaper. At this stage, certain assumptions about the design of the part are verified, which sometimes turn out to be different from reality. Sometimes it is assumed that more expensive or more difficult-to-machine materials are used without sufficient translation into the production effect. When we identify the role of individual materials thanks to DFM, we have a chance to reduce production costs.

However, these are not all the benefits of the analysis- DFM makes it possible to find the best compositions of materials and technologies. This, in turn, leads to the creation of parts with even better performance, for example, more durable or better supporting driving physics. In addition, DFM has a huge impact on the manufacturing process itself; careful analysis significantly reduces the risks involved in manufacturing a component. We can verify that design assumptions are reflected in real-world conditions and that the part will actually behave as we assumed.

LOWER RISK OF UNEXPECTED DELAYS AND COSTS

Every modification and delay, as well as a possible redesign, are further costs. These can add up to sizable expenses, incurred without justification. To prevent them, it is enough to implement DFM into the production process – at an early enough stage.

If we skip DFM altogether or perform the analysis in an inadequate manner, there is a risk that the developed injection mold will not be suitable for proper use. In such a situation, we have two choices. The first is to try to modify the mold and make it function in the desired way. The second is to abandon the original mold in order to create a new solution that is free of the mistakes of its predecessor. When it is crucial to reduce the production time, however, both solutions can be a big obstacle. Such a situation should not happen – if we have the opportunity, we should definitely try to avoid it.

DFM IN MANUFACTURING: REDUCE PRODUCTION TIME AND COSTS WITH KNAUF AUTOMOTIVE

At Knauf Automotive, we strive to combine the virtues of Design for Manufacturing with the idea of reducing the time spent on implementing new solutions. When working with our customers, we are committed to generating as much added value as possible from our experience and technological background.

download case study of cooperation in one-stop-shop model

Thanks to appropriate production strategies and the advanced knowledge of our experts, we perform DFM at a very early production stage with extremely strict simulation conditions. We use the support of CAE (computer-aided engineering) programs to most effectively analyze the parameters of a component and optimize its production. Professional tools and qualified personnel are a combination that allows us to provide very comprehensive analyses that take into account virtually every element of a specific part's specification: shape, unique mechanical features, aesthetic aspects and production cost.