Although the era of lithium-ion batteries began only in the 1990s, they have already managed to revolutionize not only the small electronics segment, but also the transport and energy sector. The technology is evolving at an ever-increasing pace, and all indications are that modern lithium-ion batteries will soon be powering the development of many strategic areas of modern industry, with the automotive industry at the forefront.

The market for lithium-ion cells is growing rapidly, despite the supply crisis caused by coronavirus. It is forecast to reach a value of around $84 billion as early as 2025. Electric car manufacturers are responsible for nearly 40% of the demand, and it continues to grow. It is estimated that by 2040, about 70% of vehicles in use will be electric cars. This translates into five times more automotive market demand than current production capacity. Rapidly growing demand for lithium-ion batteries will in the long term mean an increase in their production and consequently a decrease in their prices, due to economies of scale. In the last ten years, lithium-ion batteries have already fallen by 90%, and everything indicates that this trend will continue in the future. This allows us to forecast that in a short period of time, the prices of electric cars will be equal to those of combustion engine cars.

Electric car price is going to decrease?

It is estimated that the cost of a lithium-ion battery currently accounts for about 35-40% of the price of an electric car, while some time ago its share was estimated at up to 80%. Experts predict that by the time the price of lithium-ion batteries reaches $100 per kilowatt hour, the cost of buying a combustion car and an electric car will be similar. As recently as 2020, it was $137 per kilowatt hour, meaning that this moment could happen soon, although it will likely be delayed somewhat due to the global increase in commodity prices due to the effects of the coronavirus pandemic. Indeed, the prices of metals needed to make car batteries have increased by about 40%, but this is a temporary trend. Manufacturers predict that in the future, optimization of mining, cell production and the electric vehicles themselves will reduce the average price of electric cars even by up to 56%.

What does the price of an electric car battery depend on?

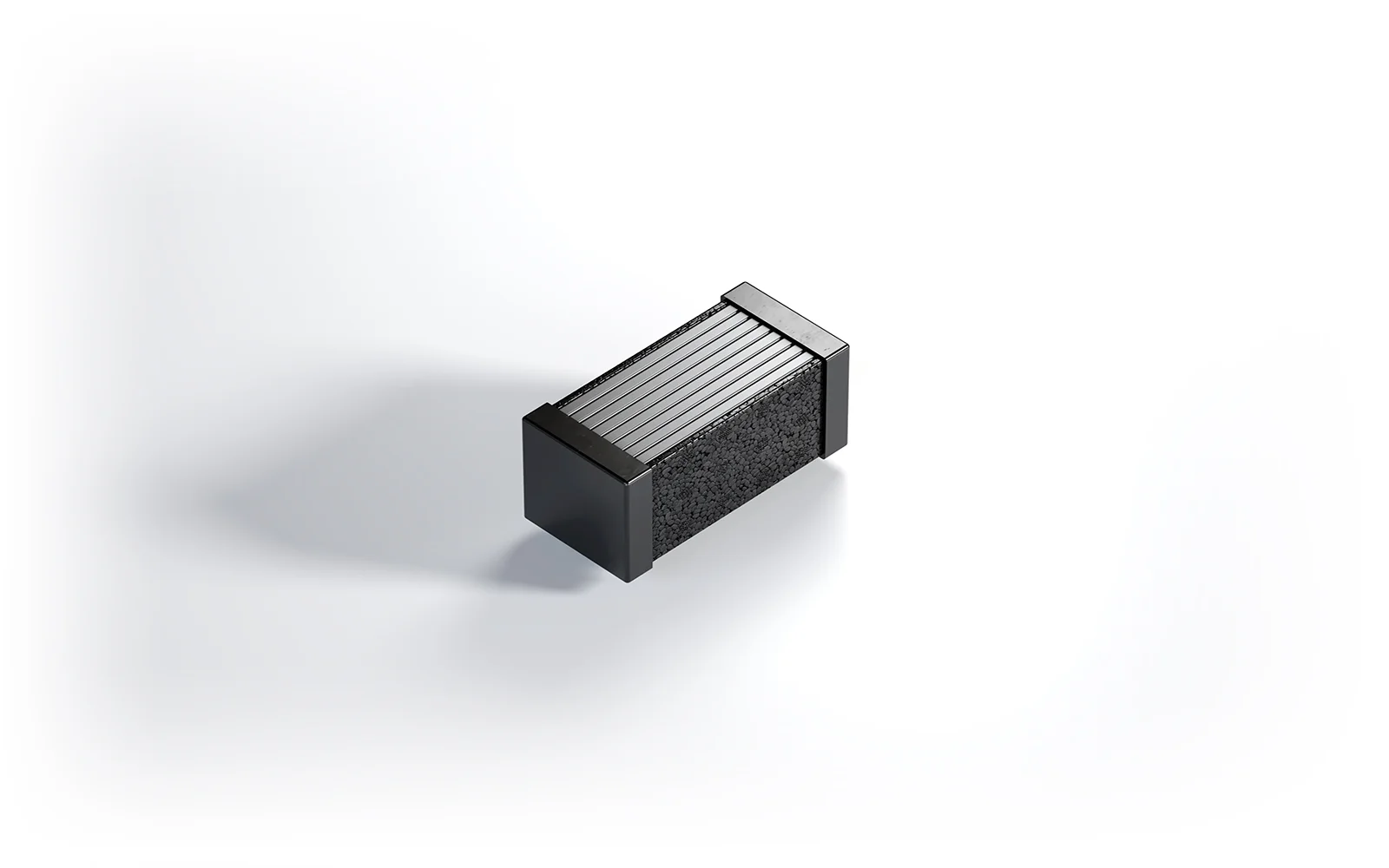

Today, the biggest impact on the cost of producing lithium-ion batteries comes from the rare earth raw materials needed to make them. As BloombergNEF reports, the high cost of mining the metals that make up the cathode, such as lithium, nickel, cobalt, and magnesium, makes it contribute as much as 51% to the price of the entire battery. The second largest component of the price of lithium-ion batteries are the “pure” production costs in factories, i.e. the costs of labour, manufacturing and depreciation of equipment. They account for as much as 24% of the total battery price, which is more than the cost of the anode (12%) and electrolyte (7%). Another 7% are production costs of battery components for electric cars, such as cell separators and casings. These elements are very important for proper functioning of the battery, as they prevent possible electric breakdown and protect the battery's sensitive elements from various types of damage. Regardless of the cost of extraction of raw materials, lithium-ion battery manufacturers have a great potential to develop, which is the efficiency of their production in their own factories. One technology that can increase the economics of casing production and cell insulation is foamed polypropylene (EPP), from which Knauf Industries produces durable battery packs using modern compression moulding technology.

Reliable battery protection for your electric car

Decisive for the durability and lifetime of an electric car battery is the way it is used and the conditions in which it has to work. The optimum operating temperature range is 20-25°C, so in addition to an effective cooling and heating system, manufacturers use insulating elements to provide thermal and electrical protection for the cells. Polypropylene foam (EPP) is ideal for this type of application. Complete battery insulation kits for electric cars manufactured from EPP are extremely lightweight, which means they don't add weight to the battery, while also being very durable and mechanically resistant. Due to its thermal insulation properties, EPP foam prevents the transmission of high temperatures between the cells, and is also resistant to fire and high temperatures. Furthermore, due to its very high breakdown voltage value, it minimises the risk of current flow between the cells in a car battery. Due to the fact that this material has a foam structure, it absorbs shocks perfectly and does not undergo permanent deformation, but returns to its previous shape, retaining all its properties. All this makes foamed polypropylene universally applicable in the production of lithium-ion batteries – battery cell separators, all kinds of heat insulating elements and connection and mounting rails, which successfully replace traditional solutions requiring the use of additional tools.