Knauf Automotive

Hybrid cars

Hybrids: development, pros, and cons of hybrid cars

The development of hybrid cars is inextricably linked to the continuous improvement of the materials used in their construction, such as EPP and EPS. These innovative thermoplastics play an important role in shaping the safe and comfortable interiors of hybrid vehicles. Their unique properties, such as lightness, strength and insulation, contribute to improving energy efficiency, passive safety and passenger comfort.

Latest articles

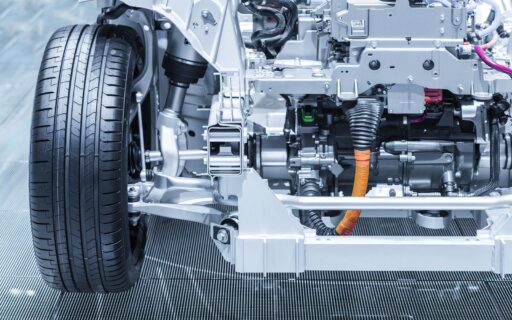

The development of hybrid cars

The concept of hybrid cars dates back a long time, but the first viable prototypes did not appear until the 1990s. Early designs combined an internal combustion engine with electric drive components, introducing innovative technological solutions such as energy recuperation during braking.

The turning point in the history of hybrids came in 1997, when Toyota launched the Prius model, the first mass-produced hybrid car. This pioneering vehicle became a milestone, ushering in mass production and the widespread adoption of this type of drive.

Over the past few decades, hybrid cars have undergone a significant evolution. Their popularity is steadily increasing, driven by tighter emissions regulations and rising fuel prices. Manufacturers are continually refining the technology with newer and newer features.

Types of hybrids

Today, three main types of hybrid cars can be distinguished:

- Full hybrids – use both an internal combustion engine and an electric motor, with the latter playing a supporting role.

- Mild hybrids – equipped with a light electric system that supports the internal combustion engine, but does not allow them to run solely on electricity.

- Plug-in hybrids (PHEVs) – have large batteries that can be recharged from a socket, allowing you to drive on electric power alone.

Find out: What is the future of HEVs (hybrid electric vehicles)?

Advantages of hybrid cars

The combination of electric and combustion engines operating in hybrid cars significantly reduces fuel requirements, especially in urban conditions. Plug-in hybrids additionally allow driving on electric drive alone over short distances.

Hybrid cars also emit less carbon dioxide compared to traditional combustion vehicles. This contributes to improving air quality in cities, making them greener. Hybrid owners can also expect tangible savings, especially in urban conditions where fuel consumption is lower. In addition, the running costs of these vehicles are lower due to less wear and tear on the brakes, among other factors.

Hybrid cars are also characterised by quieter operation of the electric motor, especially at start-up and in city traffic. This provides greater acoustic comfort and smoother acceleration.

Disadvantages of hybrid cars

The purchase price of a hybrid car is higher compared to its combustion counterpart. This implies a mark-up for opting for advanced hybrid technology. Furthermore, the battery capacity, especially in non-grid-charged hybrids, is limited. Furthermore, after several years of use, costly battery replacement may be necessary.

Another aspect is that hybrids are heavier than combustion cars due to the additional components such as the electric motor and batteries. This can have a negative impact on driving dynamics. The electric motor in hybrid cars has little impact on fuel consumption at high speeds. Therefore, hybrids show greater efficiency in urban conditions than on longer journeys.

Read also: Hybrid cars are becoming increasingly popular, but do they work well in winter?

The role of EPP and EPS in hybrid car construction

EPP (expanded polypropylene) is a lightweight and strong material that is used in the interior construction of hybrid vehicles, including dashboards, car seats and side door panels. The use of EPP helps to reduce the weight of the vehicle, which translates into improved fuel efficiency and increased electric range.

EPS (expanded polystyrene) is a foam material used to for spacers and inserts to fill voids in vehicle structures as well as for packaging for car batteries. The use of EPS also contributes to reducing vehicle weight. In addition, EPP and EPS have better insulating properties, improving acoustic comfort and thermal efficiency.

The challenge for hybrid car manufacturers is to ensure that the materials used, including EPP and EPS, are fully recyclable. Advances in fully recyclable materials are addressing the sustainability needs of the industry.