Thanks to our extensive experience and advanced processing methods, we offer comprehensive solutions for the automotive industry based on lightweight, durable and fully recyclable plastics such as expanded polypropylene (EPP), expanded polystyrene (EPS) and RELOOPP® – an innovative material. Smart design, state-of-the-art processing technologies, as well as using secondary and renewable raw materials enables optimising production, reducing CO2 emissions and improving the energy efficiency of vehicles. Learn more about the materials that are shaping the future of sustainable mobility!

Modern plastics for the automotive industry

The automotive industry owes a lot to plastics. Thanks to their unique properties such as low weight, strength and energy damping characteristics, EPP and EPS automotive components quickly became a staple in passive safety systems. Innovative expanded plastics, such as EPP (expanded polypropylene) and EPS (expanded polystyrene) provide excellent thermal and acoustic insulation, but they also have a very important impact on today's sustainable automotive industry. The logical next step in the development of these materials is to develop even more sustainable variants that reduce the carbon footprint of production. These include RELOOPP® and NEOPS®.

Expanded polypropylene (EPP)

With air content of nearly 95%, the foamy structure of EPP makes it extremely lightweight, yet strong and resistant to repeated impacts. Its distinguishing feature is its ability to deform under stress and return to its original shape afterwards. Thanks to this, parts made out of EPP do not break into pieces under load or become permanently deformed. This property meant that EPP could revolutionise automotive production, in particular when it comes to passive safety devices and other key areas.

The excellent energy-absorbing properties of this material contributed to its widespread use in structural components, seats and battery covers. EPP car seats are not only extremely safe, but also comfortable for their users. The ease of forming the material means that it can be used to manufacture objects with any shape, which promotes the development of interior designs that provide better ergonomics and aesthetics. 100% recyclability is another key boon of EPP from the point of view of environmental protection and reducing resource consumption.

Check out all the advantage of EPP and discover our solutions!

Neopolen® – EPP reaches new heights

Neopolen® – a top-quality EPP material, consists mainly of closed air cells and thus provides excellent energy absorption, minimal weight and high thermal stability. As such, it offers reliable performance in a wide range of demanding applications, including those where high temperature resistance is required. With its high resistance to static and dynamic loads, as well as chemical and oil resistance, Neopolen® can be used in the engine bay and other places, where performance matters. The raw material is available in a wide range of densities from 20 to 100 g/l, a broad colour palette and special variants, which can provide reduced electrical and thermal conductivity – all to enable you to find the right material for every application.

Choose state-of-the-art solutions – find out more about Neopolen®

RELOOPP® – recycled EPP

RELOOPP® was developed by Knauf Industries in response to the need for more sustainable plastics and is an ideal alternative to conventional expanded polypropylene (EPP). It is made of 90% post-consumer EPP waste, which is then mechanically recycled and reformed into new material with great properties. Thanks to this process, RELOOPP® is a solution for the age of the circular economy, which reduces waste and the consumption of virgin raw materials, all while retaining all the properties of its brand new equivalent. This in turn makes it the best choice for manufacturing ultralight passive safety system components, car seat parts and packaging.

The introduction of RELOOPP® is Knauf Industries' contribution to the development of sustainable material solutions.

Expanded polystyrene (EPS)

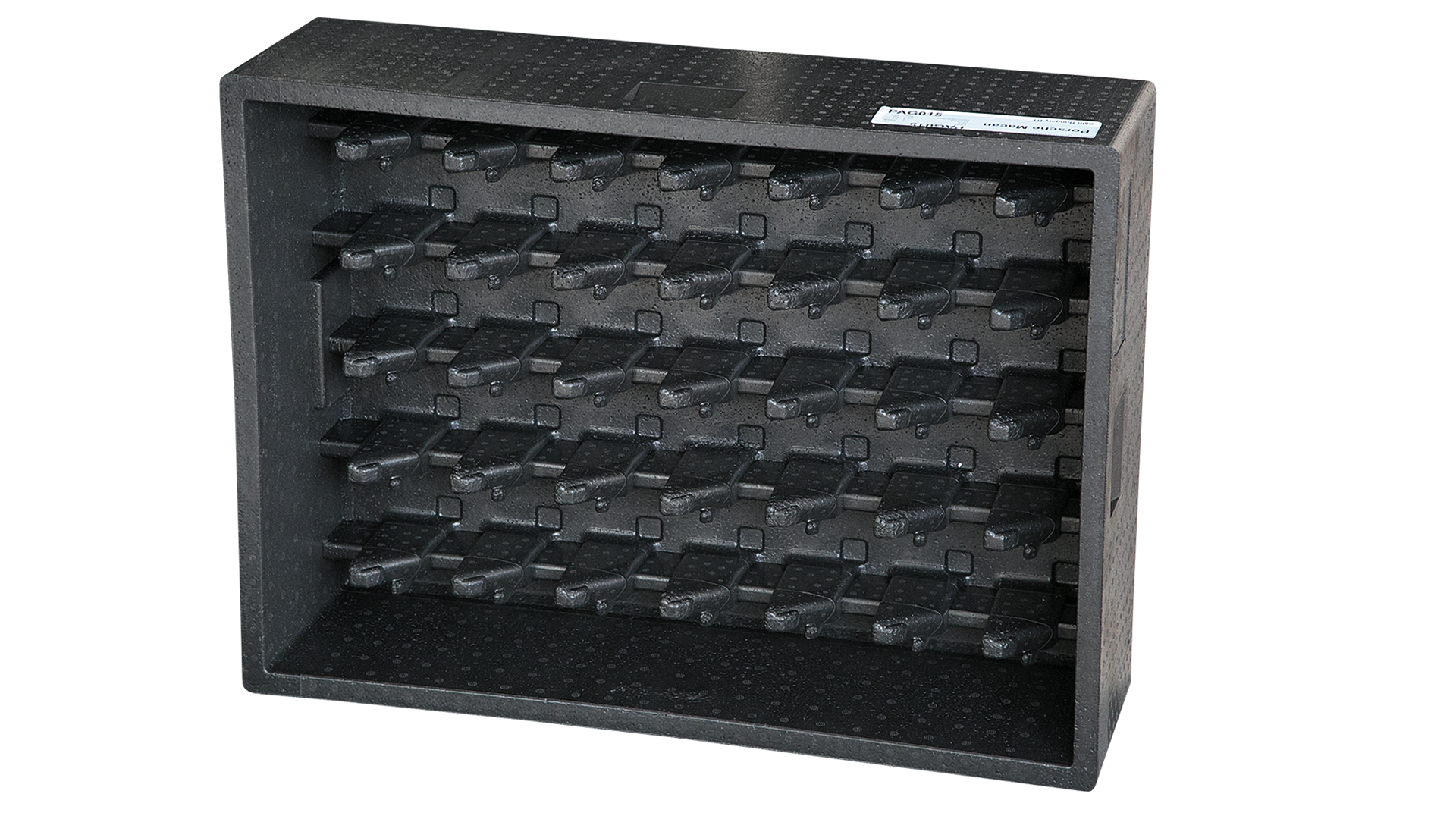

EPS is an extremely lightweight material that contains as much as 98% air, which makes it a perfect choice for applications where the main goal is to reduce the mass of the vehicle. Components made of EPS are characterised by excellent thermal and acoustic insulation properties coupled with great damping performance. This makes them particularly suitable for cushioning and component protection. EPS is widely used in the production of transport packaging for automotive parts, but also in vehicle design. Depending on its density, it can also work well as a floor, boot or car door filler.

NEOPS® – the next generation of EPS

NEOPS® is an innovative expanded material developed by Knauf Industries, which makes for an excellent alternative to conventional expanded polystyrene (EPS). The material, which is made out of Biomass Balance obtained from renewable raw materials, reduces carbon footprint by up to 30% and lowers the consumption of fossil fuels.

At the same time, NEOPS® retains all the advantages of conventional EPS, such as very low weight and high mechanical resistance, chemical neutrality and easy moulding. Thanks to these characteristics, it is perfect for insulation products, industrial and food packaging, as well as technical parts. Like EPS, it is fully recyclable, which makes it fully compatible with the principles of circular economy.

CELOOPS®

CELOOPS® is an innovative material developed by Knauf Industries, made entirely from post-consumer recycled plastic waste. CELOOPS® offers the same technical specifications as conventional EPS, including light weight, durability, shock absorption, and resistance to moisture and microbial growth. It is suitable for use in food packaging, industrial applications, and technical components. Additionally, CELOOPS® is recyclable through existing EPS recycling channels and the Knauf Circular® recovery program, supporting the transition to a more circular and sustainable plastics economy.

Key benefits of our materials

Our state-of-the-art expanded plastics not only meet the most stringent safety and food transport requirements but also promote sustainability.

Lightweight materials made of mostly air are an extremely effective solution for automotive projects, as they reduce the tare weight of vehicles and thus their energy requirements. Thanks to their damping and heat-insulating properties, interior parts made of EPP and EPS effectively protect passengers from the impact of accidents and improve comfort thanks to thermal performance and noise reduction. Exterior EPP car parts have a crucial impact on pedestrian safety. In addition, they are the perfect answer to sustainability needs of the OEMs and the requirements of circular economy, as they are 100% recyclable. On the other hand, their great mouldability makes them extremely cost effective. Flexible manufacturing processes enable the mass production of parts of any shape, which promotes the development of customised and innovative solutions.

Our approach to innovation and recycling

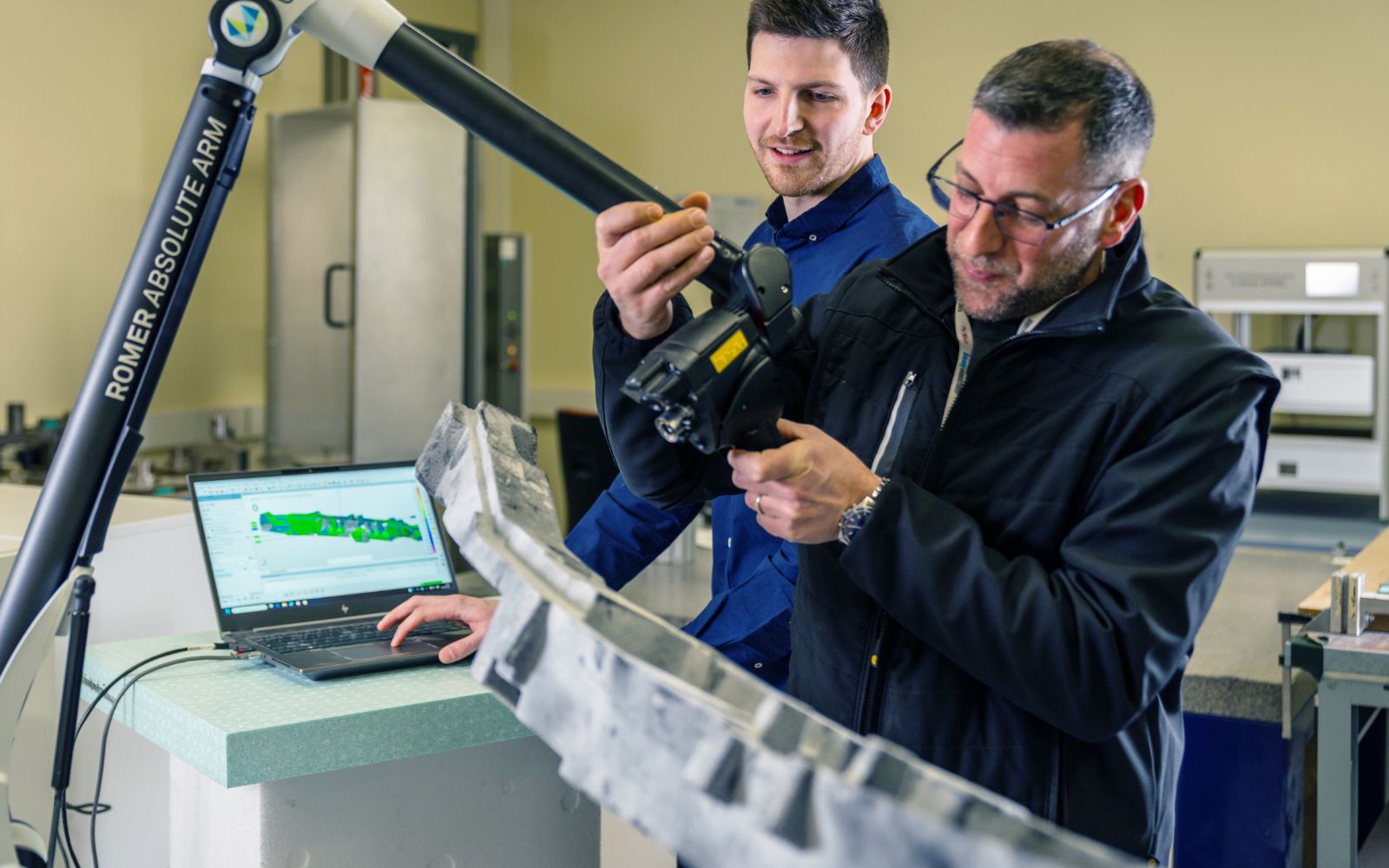

The history of the automotive industry is one of continuous progress, which is why our ID Lab Innovation Centre focuses on designing and manufacturing plastic components using innovative technologies. Thanks to close cooperation with experts and a modern approach to mechanical and chemical recycling, we are able to develop innovative solutions tailored to the needs of various industries, including the automotive sector and transport packaging manufacturers. In response to the need to lower industrial emissions, we are working on sustainable expanded plastics that lower the demand for virgin raw materials thanks to using renewable resources or manufacturing with biomass balance.

We use advanced techniques and tools, including 3D printing, 3D scanners and numerical simulation in our development work, which enables us to test new products and achieve even better results. As a result, we are able to effectively support our partners in the use of green materials and significantly shorten the process of bringing products to market, while improving their quality.

Examples of applications for innovative expanded plastics

Modern production technologies allow us to precisely control the parameters of our products in accordance with customer expectations or a specific application. Depending on their parameters in terms of density, hardness or compression and impact resistance, these materials can be used in the production of car bumpers, seats, vehicle interiors, extremely lightweight sun visors and protective transport packaging for fragile automotive components.

Compared to hard plastics, they stand out thanks to their excellent thermal and acoustic insulation, as well as their impact resistance, which enables combining them with parts that require increased cushioning. Some of them also perform well in extreme conditions. For instance, EPP can be made in a way that ensures better resistance to high temperatures and arcing, which makes it suitable for use in EV battery housings and hydrogen tank shells.

Plastics used in injection molding technology

In injection molding technology used for the production of automotive components, materials with high durability, temperature resistance, and design flexibility play a key role. At Knauf Industries we use a wide range of plastics, such as PP (polypropylene) and PP/EPDM, which offer good chemical resistance and flexibility—ideal for both exterior and interior automotive applications. ABS and PC/ABS combine mechanical strength with an aesthetic finish, making them well-suited for cockpit components and housings. PA6 GF30 (glass fiber reinforced polyamide) and PP GF30 are reinforced materials used where exceptional rigidity is required, such as in seat structures, brackets, or structural elements. Depending on customer requirements, we can also use materials such as PC, PC/PMMA, and PS (polystyrene), which is suitable for manufacturing simpler components with lower mechanical demands. The selection of the appropriate plastic depends on the function of the component, its location within the vehicle, and specific quality and environmental requirements.

Plastics in the automotive industry – FAQ

What are the main benefits of using expanded plastics in the automotive sector?

Expanded plastics offer many advantages in automotive applications. They improve energy efficiency, safety and sustainability. They are much lighter than traditional materials such as metal, felt, rubber and hard plastics. This results in weight reduction and contributes to lower fuel consumption and CO2 emissions. At the same time, these materials are characterised by well-proven thermal insulation and noise reduction properties, which increase passenger comfort.

Due to the ease of moulding, expanded plastics enable manufacturers to achieve any complex shapes. Because of that, they can be used for manufacturing car bumpers, dashboards and component housings, which not only improve functionality and aesthetics, but also provide design freedom. The use of expanded materials in the automotive industry contributes to its sustainability. Many of them, such as RELOOPP®, can be manufactured from recycled raw materials, which aligns with circular economy principles. It is also worth noting that unlike metal parts, components made of expanded plastics are not susceptible to corrosion, contributing to extended lifespan of vehicles.

What is the difference between EPP and EPS? Which one is better for my automotive projects?

EPP (expanded polypropylene) and EPS (expanded polystyrene) are different in many aspects. EPP is not susceptible to permanent deformation and returns to its previous shape when the tension is relieved, which makes it the perfect choice for manufacturing cushioning components such as bumper dampers and headrest fillings. EPP is also highly resistant to high temperatures, which means that it can be used in the engine bay and near other heat sources. EPS, on the other hand, is more susceptible to permanent deformation and can crumble. That is why it is best suited to applications where lower load, impact and temperature resistance is required. As far as sustainability is concerned, both EPP and EPS can be recycled, but in the case of EPS the process is a bit more complicated. Despite its weaker mechanical properties, EPS is cheaper to process and more cost-effective, which can be a big advantage in some applications, such as the production of filling components or disposable packaging.

Are EPP, EPS, RELOOPP® CELOOPS and NEOPS® recyclable?

Yes, all these materials are fully recyclable, although the processes are different in each case. In the case of EPP (expanded polypropylene), the material is first crushed, then melted and reformed into new products. This process can be used to make materials such as RELOOPP® (EPP with recycled content) which is also fully recyclable. The recycling process for EPS (and its more sustainable alternatives – NEOPS® and CELOOPS) looks similar; however, air needs to be removed before the parts can be shredded. Despite being slightly more cumbersome, the process is fully refined and successfully used by many recyclers. The resulting high-quality raw material is reused for thermal insulation and packaging. The materials are designed with sustainability and circular economy in mind.

How does the use of lightweight plastics affect vehicle efficiency?

The use of lightweight expanded plastics can impact efficiency in a number of ways. The most important and apparent one concerns weight reduction. Lighter cars use less fuel. In the case of EVs, they can go farther on a single charge, thus lowering their operating cost. Expanded plastics also offer better thermal insulation properties than other conventional materials, which improves the efficiency of air conditioning and heating systems. Materials such as EPP and RELOOPP® are also strong and resistant to deformation, making them perfect for manufacturing components that absorb impact energy in the event of a collision, such as bumpers or headrests. What is more, sustainable plastics, such as CELOOPS and RELOOPP®, are made of recycled raw materials and NEOPS® based on mass balance principle which promotes circular economy and improves the environmental performance of cars.

Which automotive components can be made out of EPP and EPS?

Both EPP (expanded polypropylene) and EPS (expanded polystyrene) can be found in car designs; however, their different mechanical properties affect their areas of application. EPP has the so-called shape memory – it is resistant to deformation and repeated impacts, making it more versatile. Thanks to this property, it is used for making bumpers and crash-absorbing components such as headrests, armrests and door panels. It is also suitable for battery insulation systems in electric vehicles, due to its resistance to high temperatures and electrostatic properties. EPS, on the other hand, is lighter and slightly less impact resistant, making it suitable for less demanding applications such as dashboard infill panels and floor structures, insulation in air conditioning systems, as well as transport packaging for automotive components.