SURFACE TEXTURING OF EPP AUTOMOTIVE PARTS

The combination of extensive experience and digital technologies has made it possible to texture graphic forms on the surface of EPP material more accurately than ever before. This has made it an attractive alternative to traditional foam parts that require additional decorative finishing.

HIGH QUALITY OF TEXTURING PROCESS

The tools we have developed allow us to increase the quality and clarity of the texture, while applying it in a more environmentally friendly process than before. Grain effect patterns are created with precision down to the smallest detail, giving manufactured parts made from EPP a very fine, luxurious look. This means that purely technical EPP automotive parts gain a new aesthetic value. They can now successfully replace traditional foam solutions, which are usually painted, covered with fabric or other external coating. Not only can such “mono-material” parts be produced more easily and quickly, but they are also lighter and 100% recyclable.

36 UNIQUE DESIGNS – KNAUF INDUSTRIES' OWN TEXTURE COLLECTION FOR EPP AUTOMOTIVE PARTS

We consider custom textures as a kind of added value for the customer. Thanks to the available palette of designs in line with the latest trends, our know-how and technological support, he can now realize an individual project “from A to Z” in one place. The use of an aesthetically pleasing, high-quality material texture on EPP automotive parts means that they can achieve an attractive design. Parts produced entirely from a single material, such as EPP, are not only more environmentally friendly but also feature minimal weight. It's worth noting that reducing the weight of vehicles is a critical issue in the automotive industry today, as it helps reduce their emissions.

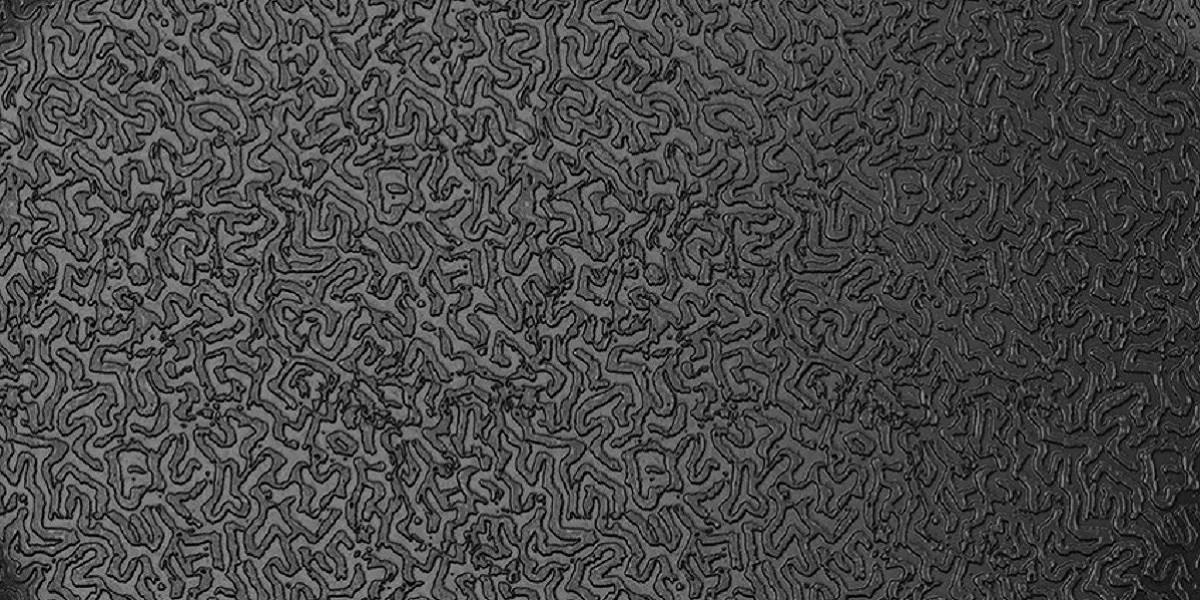

Knauf Industries' texture design is a reference to the unique properties of expanded polypropylene (EPP), which is produced using a process that uses little energy and water. The range currently includes four lines that are inspired by materials and forms found in nature. In addition, they have been designed to look visually appealing on the surfaces of EPP automotive parts. The Desert line is a selection of surfaces that resemble the texture of desert sand. The Fabric collection includes fabric textures woven from natural fibers. The Ceramic line is based on the aesthetics of natural stones and provides an interesting, distinctive aesthetic effect. The Flora line, on the other hand, is an example of sophisticated design based on floral forms. However, it is essential to remember that our new texture collection is much more than a fashionable design. It signifies even closer cooperation with the customer and a wider range of services than before.

CUSTOMIZED TEXTURED DESIGN PROCESS

Upon request, we can apply any texture to the parts. Before this happens, however, we make professional visualizations of the final EPP automotive parts using state-of-the-art digital tools. Using techniques such as high-resolution 3D rendering, we can precisely superimpose a texture visualization onto an already existing component. Based on a reality-compatible, life-size digital prototype, the customer can more easily make a choice of the optimal solution. Modern plastic processing technologies and IT solutions significantly expand the boundaries of creativity, we can easily and quickly apply any optimization at this stage, giving the project a completely different look.

We believe that design must go hand in hand with appropriate technical parameters. Material properties such as thermal insulation, mechanical strength or flexibility are of great importance in the automotive parts industry, which is why an already made prototype can be subjected to assembly tests and simulations – either on-site or in a certified external laboratory.

PROJECT IMPLEMENTATION FROM “A” TO “Z” FOR EPP AUTOMOTIVE PARTS – SUPPORT AT EVERY STAGE OF THE PROCESS

At Knauf Industries, we coordinate the process of creating molds based on provided documentation from the customer and carry out the production of foamed materials automotive parts. The parts, thanks to the appropriate design of production tools, can undergo precise texturing based on a pattern selected by the customer from a catalog. As a result, he does not have to buy the pattern externally or order its manufacture, which reduces the time and cost of the project.

WHY CHOOSE KNAUF AUTOMOTIVE EPP TEXTURING SERVICES?

Aesthetically pleasing textured EPP automotive parts can now be made more visible at the same time, while retaining the material's distinctive features, such as light weight and total recyclability. High-quality textured surfaces, moreover, make it possible to give plastic car parts unique qualities that can be perceived with more than one sense. They can not only be seen, but also touched.