What is Double Action Technology?

DAT (Double Action Technology) is an innovative approach to mold EPP foam parts. It combines advanced engineering based on 3D printing with robust materials. The DAT tools are light, strong and improve the quality of the EPP surface. In addition, the DAT process requires much less energy than conventional technologies. DAT cuts the CO2 emissions by half.

Why choose DAT?

DAT is ideally suited to the requirement of sustainability in the automotive industry. This is because the moulds require less energy to heat up and to cool down. This translates into more efficient and more sustainable process, which is especially beneficial for high-volume production. DAT technology is also ideal wherever a perfect surface finish with no visible vent marks is important for functional or aesthetic reasons. Depending on the desired effect you can choose from technical anti-slip textures, natural textures such as leather, wood or stone. With DAT the creation of a thin, solid, pore-free layer of solid PP is possible in the foaming process. An additional advantage of this technology is the longer tool life compared to conventional aluminium moulds.

The secret to DAT efficiency

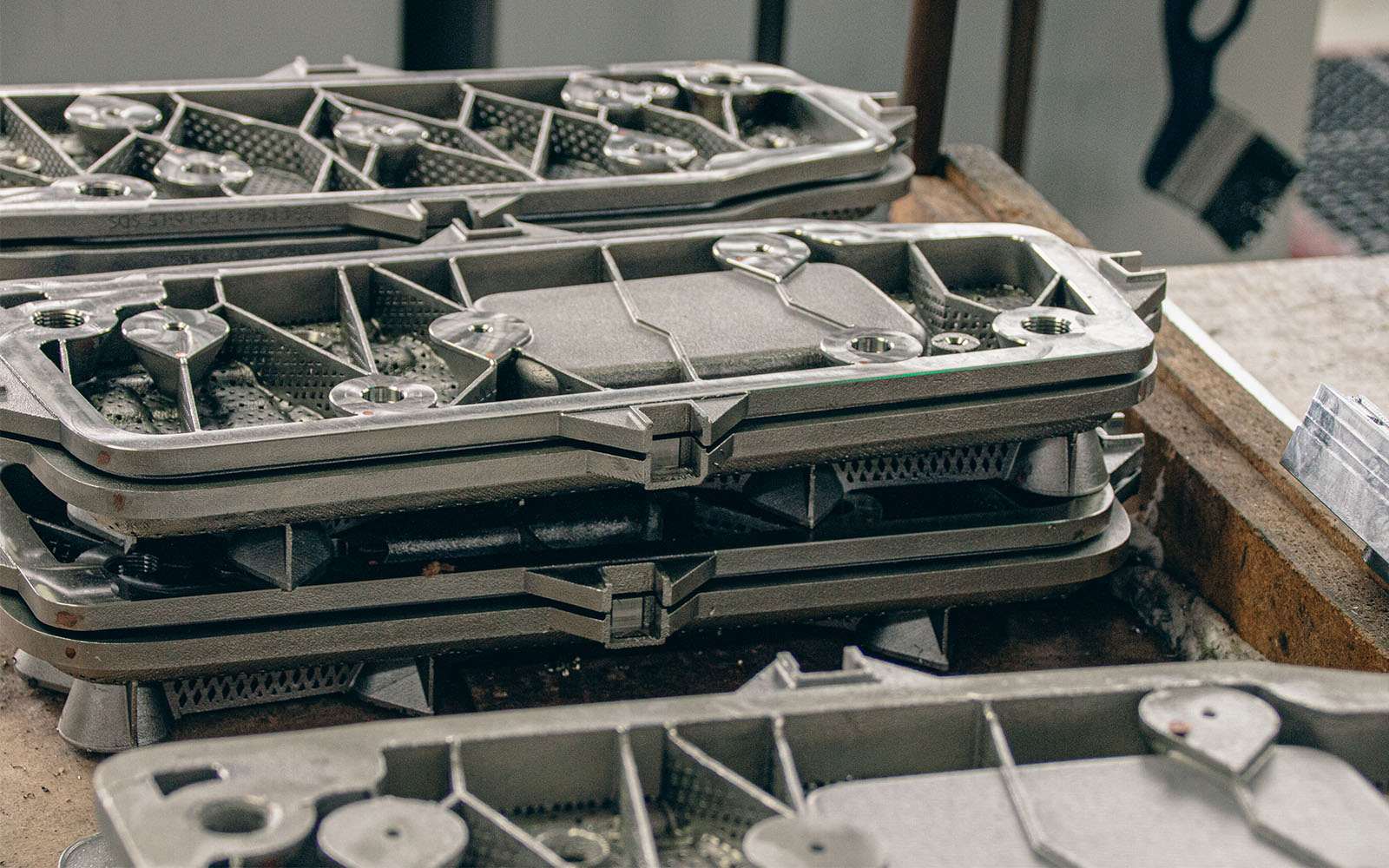

What determines the unique advantages of DAT technology? The secret lies in the innovative design of the moulds and better use of material properties. Thin-walled, hollow stainless steel is used instead of thick-walled aluminum for their manufacture. The moulds can only be manufactured with 3D printing, a novel technology which is mastered by the Knauf Team. DAT moulds have a special wall construction: A closed volume all along the surface can be used to flow cooling water or steam in it. This allows fast temperature changes of the mould in seconds while ensuring high homogeneity. With this concept, the cooling water stays inside the tool and comes never in direct contact with the EPP part. In addition, the DAT moulds feature special micro-nozzles. Due to their small diameter you have almost invisible marks on the EPP part.

Applications of DAT technology

DAT delivers the highest value for our customers in high-volume production or in visible parts that benefit especially from the beautiful surfaces. DAT is our preferred way to manufacture the challenging sun visors. But DAT can also be used to produce other automotive technical parts as well as trays for part tansportation. DAT enables local overheating of the EPP material, which, after cooling, results in a smooth “skin” without pores. Such a surface is watertight and easy to clean, making it successful in applications requiring hygiene and water resistance. This is why DAT technology is also ideally suited for challenging projects in the packaging industry.

DAT vs. traditional technologies

The main differences between DAT and traditional manufacturing:

- DAT saves 50% of CO2 in the moulding process

- DAT enables beautiful surfaces of the EPP part

- DAT makes the production process more efficient

See how DAT BENEFIts production

The production process of EPP parts with DAT technology is more cost-effective than with traditional methods. The tools are very durable and use less energy per EPP part therefore they are perfect for high-volume production.

DAT AT KNAUF INDUSTRIES

Knauf Industries' groundbreaking method of manufacturing EPP automotive components is currently protected by several patents, and the result of more than a decade of intensive development. The certification of our tool-making plant to DIN ISO 9001-2015 is a guarantee of the highest quality standards.

Frequently Asked Questions (FAQ)

What is DAT technology?

DAT stand for Double Action Technology. It is Knauf Industries' innovative method of processing EPP using special moulds produced by 3D printing. It reduces the carbon footprint of production of automotive parts and packaging.

What are the costs of implementing DAT technology?

The costs of implementing DAT technology depend on the dimensions and geometry of the components and are therefore determined on a case-by-case basis.

Will the DAT method be suitable for my production?

The DAT method works well for a wide range of projects, but is generally most beneficial for high-volume production of components with relatively flat geometries. You are welcome to contact your sales agent, who will prepare a detailed feasibility study with cost estimates. At Knauf, we always choose the most beneficial alternative for you – and DAT is often, but not always the best choice.