The automotive world is focusing on electromobility, but its development is facing problems and electric vehicles also have their drawbacks. That's why many manufacturers have not yet given up on internal combustion engines and are continuing to develop technologies to make them more efficient and minimize their environmental impact.

Under new EU regulations, the introduction of emission-intensive cars to the market will be gradually reduced. By 2030, manufacturers are required to reduce CO2 emissions of manufactured vehicles by 55% for passenger cars and 50% for light commercial vehicles. The Euro 7 standard announced in the European Union is expected to increase the cost of production of internal combustion cars after 2025, and a gradual reduction in average CO2 emissions to 0 g CO2/km by 2035 will mean that only environmentally friendly cars, such as those powered by hydrogen or electricity, can be registered in EU Member States. However, green internal combustion engines may prove to become a viable alternative.

Eco-friendly internal combustion engines – what are they and how do they work?

Eco-friendly internal combustion engines are units that have been designed or modified to reduce harmful emissions. This includes both traditional gasoline and diesel engines, soft hybrids and those using only alternative fuel sources. Modern internal combustion engines continue to evolve, with manufacturers introducing new technologies. One example is Mazda, which has developed a new six-cylinder gasoline unit and a large diesel engine in a soft hybrid system that meet stringent emission standards. Meanwhile, Porsche has offered a new six-cylinder boxer engine, which is expected to be introduced even before the company finally limits itself to electric drives only. Among the technologies using modern automotive fuels, the hydrogen engine seems especially interesting as a potential attractive alternative to both diesel and gasoline-powered cars. Manufacturers such as Toyota, China's GAC, Yamaha and Renault are currently working on a combustion hydrogen engine.

Why can the development of modern internal combustion engines be beneficial?

The development of green internal combustion engines is beneficial because it allows for a gradual transition to more environmentally friendly solutions without having to change the entire infrastructure. Currently, the biggest challenge for electromobility is the limited battery capacity and high price of electric cars. Although battery technology is constantly evolving, electric vehicles can still travel fewer miles and have longer charging times compared to traditional internal combustion or hydrogen cars. Various types of electric cars, such as extended-range hybrids, are a possible answer, but a full transition to electromobility requires extensive infrastructure, such as a sufficiently dense network of charging points and specialized service workshops. In addition, disposal of used batteries is still an unsolved problem. Due to their complex structure and rare earth content, they not only cause resource depletion, but remain also difficult to recycle. All this is causing a search for other types of fuels that are easy to obtain, process and will not cause harmful emissions to the environment. Hydrogen cell electric cars are also a problematic issue. They are expensive to produce and have a low efficiency of only 30-35%. For this reason, modern internal combustion engines that could run on environmentally friendly fuels seem to be a good off-the-shelf solution.

Types of green internal combustion engines – what modern low-emission fuels are used?

Modern low-emission fuels, such as biofuels and synthetic blends, allow significant reductions in harmful emissions. Hydrogen and ammonia engines offer almost zero emissions, so they could enter clean transportation zones, for example. Other solutions rely on advanced technologies to increase efficiency and reduce emissions, making them increasingly competitive with electric vehicles.

Hydrogen engines

Internal combustion engines using modern hydrogen fuels do not emit CO2, which is beneficial in terms of climate change. The products of combustion, in this case, are water vapor and small amounts of nitrogen oxides (NOx), which are admittedly harmful to the environment, but the use of appropriate filters offsets this problem. Low energy efficiency remains an issue, however. Hydrogen has a much lower energy density than fossil fuels (about 2-3 kWh/l compared to 11 kWh/l for diesel). This means that an internal combustion engine must burn much more hydrogen than fossil fuels, leading to low range or the need for larger fuel tanks. In a reciprocating engine, only about 30% of the fuel energy is used for propulsion. The rest is converted to heat and is removed from the system in that form. Manufacturers are working on more efficient use of hydrogen and modern hydrogen fuels. For example, in 2021, the Chinese brand GAC Motor has developed an engine that is expected to be more than 44% efficient, and has announced the development of a corresponding infrastructure.

Ammonia engines

The ammonia engine is an innovative solution that has the potential to revolutionize the automotive industry in the future. During combustion, ammonia (NH₃) does not emit carbon dioxide, but nevertheless leaves a subtle carbon footprint due to its low nitrogen oxide emissions. Instead, it is readily available and can be produced in large quantities. Unlike hydrogen, it can be stored in liquid form, making logistics much easier. Toyota and Guangzhou Automobile Group (GAC) have jointly developed a prototype ammonia engine that uses specially designed components. Precision injectors control the amount of ammonia delivered to the combustion chamber, while advanced systems reduce nitrogen oxide (NOx) emissions. It is worth mentioning, however, that ammonia itself is a toxic substance, which raises great doubts among potential users. Therefore, the use of this type of engine is at this point considered rather in the context of industrial solutions – for example, to power trucks, which today are a serious source of emissions.

Biofuels and synthetic blends

Another solution to reduce the carbon footprint of traditional internal combustion vehicles are biofuels produced from renewable resources such as plants, organic waste or algae. This makes them a greener alternative to gasoline and diesel. They are divided into biocomponents (components of liquid motor fuels) and biogas (such as biomethane). Biofuels are already successfully used in internal combustion engines, and their production and combustion have a lower environmental impact than fossil fuels. Another category is synthetic fuels, i.e. hydrocarbons or their mixtures obtained from biomass or other renewable sources. Among these are GTL (Gas to Liquid), BTL (Biomass to Liquid), SynGas, produced by forest biomass gasification processes, or SynDiesel. These are chemically produced fuels and also generate lower emissions than traditional fossil fuels.

The future of internal combustion engines

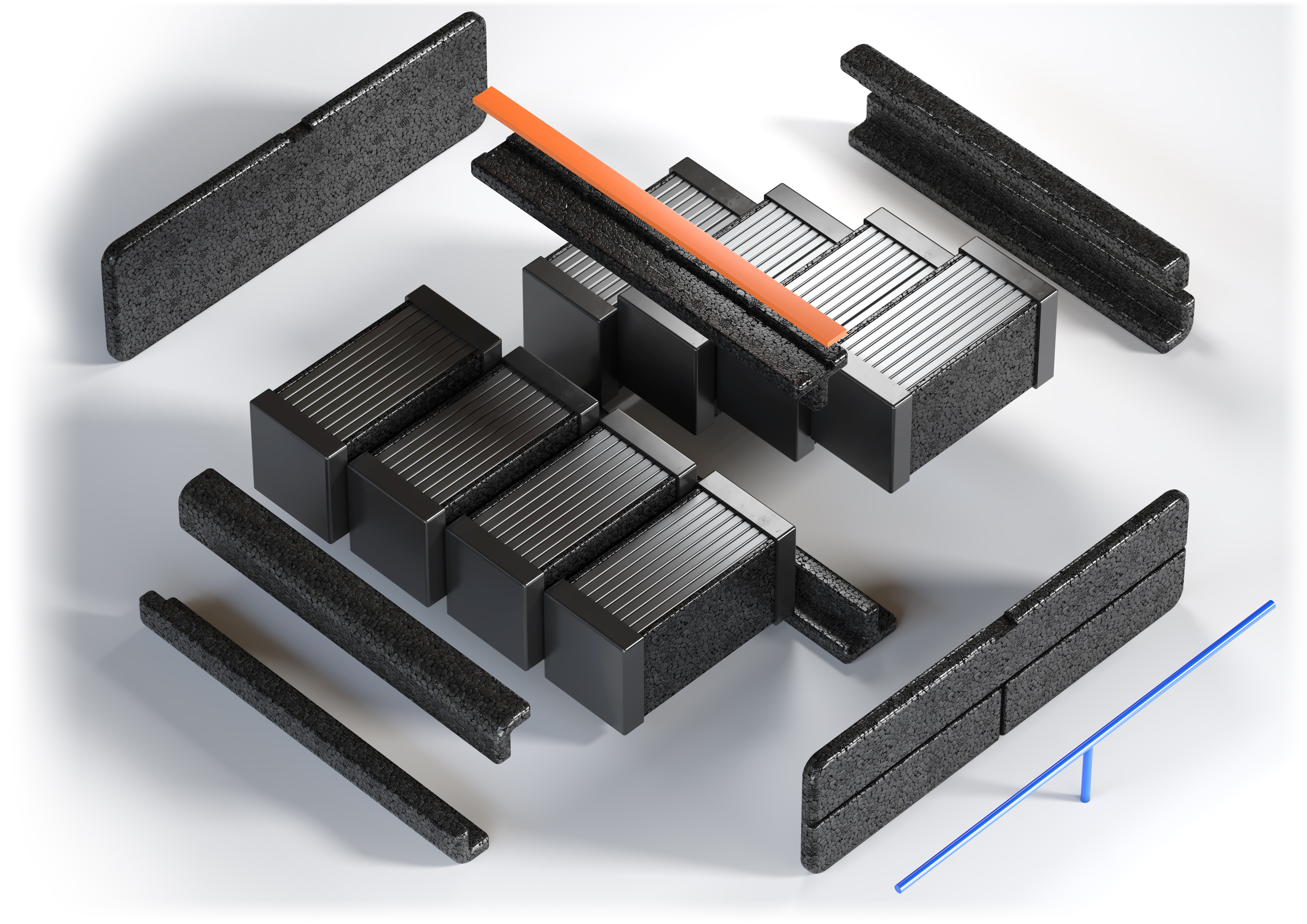

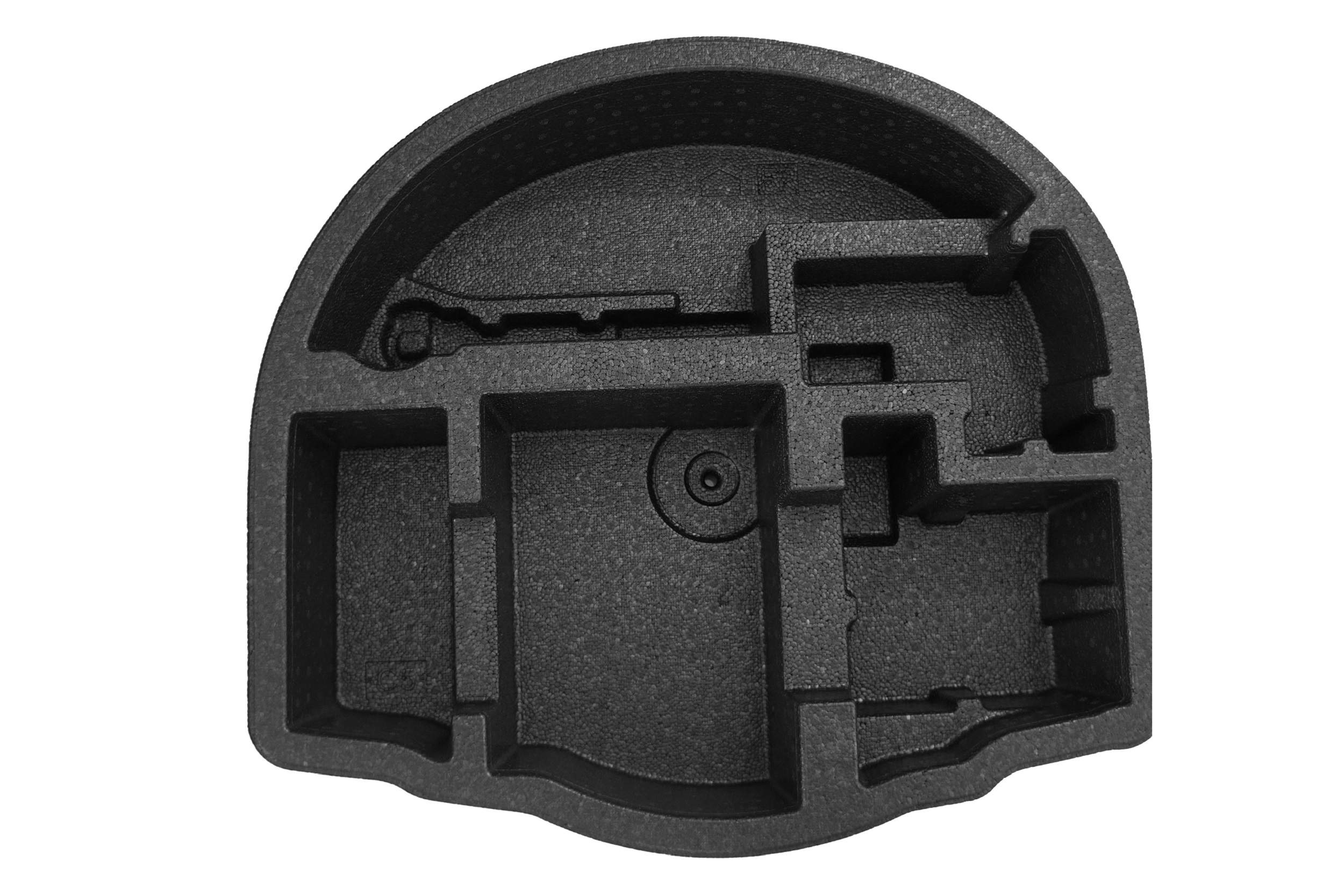

Internal combustion engines have gone through a fascinating evolutionary path, from simple designs to advanced technologies. Their impact on the development of civilization is undeniable. Despite the growing popularity of electric vehicles, some forecasts indicate that cars with gasoline or diesel engines will still be a popular choice for the next 10 years. Bosch, for example, predicts that two out of three registered cars in 2030 will run on gasoline or diesel. The ever-increasing downsizing, ever more accurate particulate filters, new materials and attempts to optimize existing series so that they can meet the strict EU requirements show that there is still plenty of room for innovation in this field – both within the engine design and the body of combustion cars. One of these is ultralight plastics, such as foamed polypropylene (EPP), for example. They make it possible to produce much lighter body parts compared to traditional hard plastic components. By lowering the vehicle's own weight, combustion can be reduced and targets required by stringent Euro standards can be achieved more easily. Many companies, including BMW, for example, have not yet set a date for phasing out the production of combustion units. This is further evidence that the technology may still have much to offer.