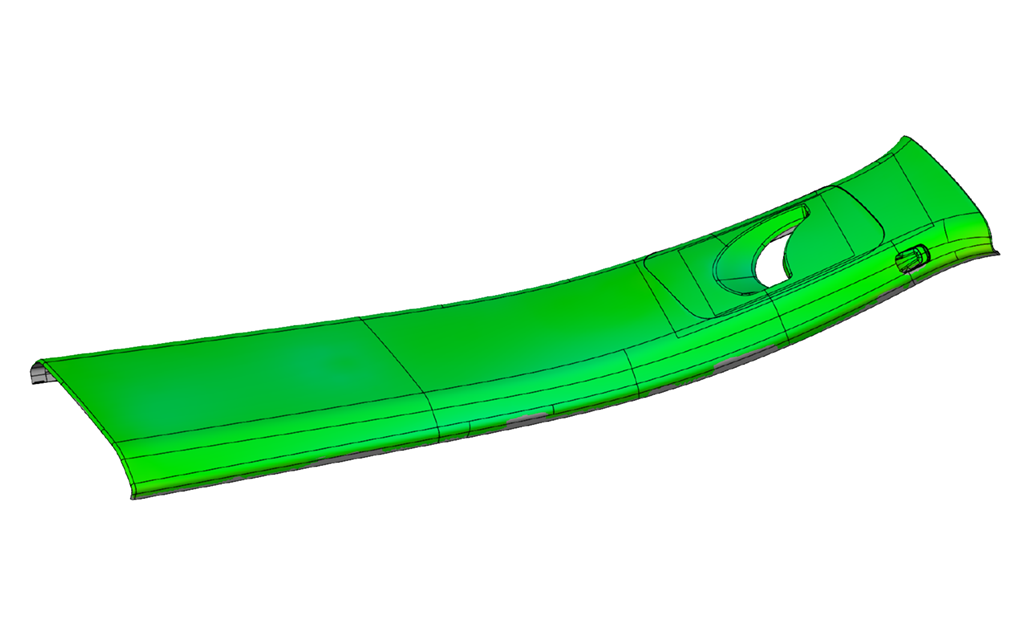

We recently opened a new measurement laboratory in our production plant located in Wrocław. Its core element is a 3D optical scanner, thanks to which we can provide our customers in the automotive industry with precise measurements of components we manufacture for them.

Another step into Industry 4.0

Components manufactured for the automotive industry must comply with the highest quality standards. Our scanner allows us to perform various measurement operations, from 3D scanning to full, automated quality control.

This way we can offer our clients:

1. The default implementation in internal quality control for all components manufactured in Knauf Industries factories.

2. A thoroughly new service for all customers who want to verify the compatibility of already manufactured components with design data.

A new service platform

This new 3D service allows us to offer you:

- immediate results of the conformity analysis;

- a quick application of the necessary corrections according to nominal parameters;

- advanced measurement services;

- faithful reproduction of the elements provided by the customer based on the digital model made in the laboratory.

The laboratory also offers a comprehensive support platform for approval processes of the new serial production parts (PPAP). It guarantees full compliance of the ordered product with the specification and the certainty that the approved series of products will have identical parameters each time.

Fully certified

The software we use in our facility has been certified by the Federal Institute of Metrology (PTB) in Germany and the National Institute of Standards and Technology (NIST) in the United States. As a result of comparative tests, it obtained category 1, which means that it shows the smallest deviations from the measurements.