Knauf INDUSTRIES

INNOVATIVE

The spirit of innovation

Welcome to our new initiative. Together with our top product and technology development experts, we have created a new space dedicated to innovation and development of cutting-edge technologies. Our main goal is to help our clients preserve their leading position in the competitive automotive market.

Our way to innovation

In response to our customers’ needs, we have set up a lab dedicated to innovation. The lab’s team will focus on the research of new solutions, business models and technologies in order to provide value for our customers. The concept of the lab is developed in our countries. Labs are working connected to cumulate the agility of local structure and the experience from a big company.

Innovative materials

To be ready to meet our customers’ expectations the moment they communicate them to us, we are constantly working on a high number of innovative materials.

Our current projects include biosourced foams, biodegradable foams, biomass balanced foams and specialty foams with thermal resistance, mechanical resistance or low COV content, as well as molded Airpop parts with guaranteed recycled content.

Time to market reduction

Thanks to our 3D scanners we can control the quality of our solutions from the initial stage to optimize the controls and provide faster feedback to our customers. We use numerical simulation software to reduce development time, as well as costs of testing and prototyping. In the final stage, we validate our solutions using 3D printing.

Added value

We use augmented reality and real rendering in our presentations, which allows us to show the product in a real environment and ensure that they’re comprehensive to all participants. Moreover, the new technology allows us to produce plastic foam parts that look more esthetic, which in turn gives our clients the possibility to target new markets, applications, and customers.

Efficiency improvement

Industry 4.0 is our reality. It is also the future of mass-scale manufacturing that can be already observed in the development of new smart factories around the world. That’s why we continuously train our employees in the implementation of new technologies.

circular economy

We understand how important it is for our clients to make eco-conscious decisions. We are able to provide bio-sourced and biodegradable foam solutions. We use eco-design to save materials and energy. The technology and process control we developed enables us to deliver to our automotive customers molded parts with a level of recycled foams guarantee. All our 42 factories are energy-efficient.

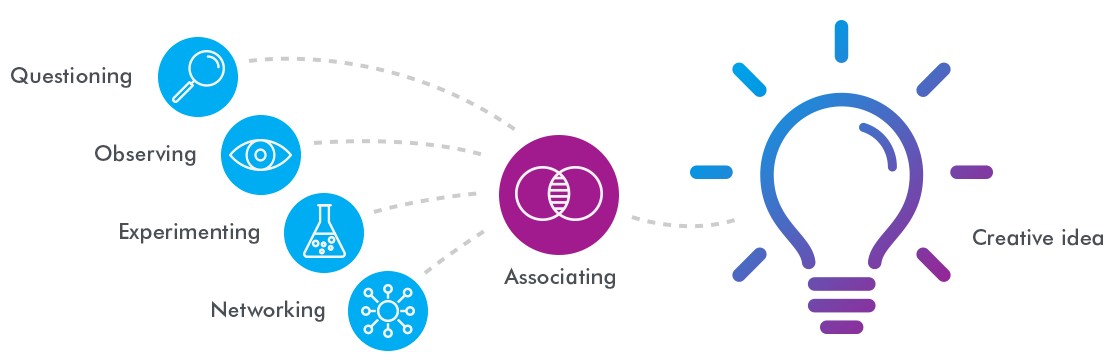

IDlab Innovator’s DNA

In our innovation process we invite our clients and suppliers to cooperate with our team in a Design Thinking model. This approach allows us to customize and test assumptions in an agile manner.