Electric cars are the key to diminish emission of the transport sector. It is possible that in the future they will also materialize the idea of the zero-emission transport. Electric motors feature the top efficiency. At present a substantial barrier influencing the limited access to electric cars are charging ports, which are still not so common. Hybrid drives could prove to be a good “transitional” alternative. What are other possibilities?

Electric cars differ in drive solutions or with the ways of replenishment of energy loss. We can distinguish a BEV (Battery Electric Vehicle), HEV (Hybrid Electric Vehicle), REEV (Range-Extended Electric Vehicle) and FCEV (Fuel Cell Electric Vehicle). The BEV is the “cleanest” kind of an electric car. It is driven with an electric motor only and features the top efficiency of energy utilization, which amounts as much as ab. 80%. To compare, in traditional combustion engines only 18 to 25% of energy generated during combustion of fuel is utilized. It is worth stressing that electric cars do not emit exhaust fumes. Moreover, assuming supplying with the current, which is not generated using fossil fuels they can be zero-emission in practice. However, their principal disadvantage is the necessity of regular battery charging and limited range of a vehicle. So, what are the perspectives and alternative solutions of the ecological transport ?

BEV cars – Energy effective but less practical?

The basic Energy source and the most expensive element in the BEV type cars is the battery. Nowadays, the lithium-ion batteries , which feature the largest energy density, find the widest application in the electric vehicles. This parameter refers to the amount of energy that can be stored in a mass or volume unit of a battery. It exerts the decisive influence on the number of kilometres, which can be covered by a car between the consecutive charges. Manufacturers are still working to improve this parameter. In spite of this, it still constitutes only 1/10 of the traditional fuel density.

Moreover, the parameters of efficiency and durability of batteries in electric cars from different manufacturers may differ from each other . Their durability depends largely on the conditions of exploitation and especially on the relevant temperature of operation. Energy loss in the BEV cars is compensated for, in a small part, by so-called regenerative braking. However, there is no doubt that the batteries, which supply the electric motor require regular charging. In relatively low availability of the car charging ports it can be problematic, not mentioning driving out of the city. Users of this kind of cars frequently point out to a long time of recharging too. An alternative may become hybrid drive cars, which get energy from other sources as well.

What are the advantages of HEV, PHEV, REEV and FCEEV cars?

In all of the hybrid cars the drive solution is a “tandem” of a combustion unit and an electric unit. They are divided into three subgroups. The first of them comprises soft hybrids, the so-called mHEV-s. in this case an electric motor does not drive a vehicle independently but plays the role of a starter and alternator. It supports a combustion engine, which transfers to lower consumption of the traditional fuel. The second group comprises full hybrids (HEV). In this solution an electric motor can drive a car independently, but for short time and at low speeds. In addition, it supports the combustion unit during acceleration. Both in the mHEV, as well as in the HEV the batteries are charged only during regenerative braking and driving with the neutral mode. It eliminates the problem with availability of charging car ports.

A possibility of charging the battery from the mains is available in the case of the plug-in type hybrids, i.e. the PHEV. Thanks to this solution you can cover even a few dozen of kilometres only on the electric motor drive. The next kind of a hybrid car is the REEV. In this case a combustion engine is used only as a supply source for the electric motor or for charging the battery. Due to this fact the unit is smaller, which also diminishes the overall weight of the car. The last category are cars with hydrogen fuel cells , which supply an electric motor, i.e. the FCEV. They feature a larger range than the BEV-s and can be charged much faster. The selection of a relevant hybrid depends on an individual way of car utilization and on personal needs.

Read more at: Hydrogen-powered cars – costs, emissions and market information

How to solve the problem of frequent charging of electric cars?

Due to the larger flexibility in exploitation issues the hybrids can be a certain alternative for cars driven with an electric unit only. However, they are much more complicated and less environment friendly. The electric units used in the BEV type vehicles are more durable, less expensive in maintenance and exploitation and quieter. Then how to solve the problem of frequent recharging – so uncomfortable for the users? The solutions that are still being worked on may include e.g. cordless charging based on the phenomenon of induction. In this case a car does not have to be connected to a charging car port, which would be much more comfortable for the users. Another comfortable option is exchanging of a flat battery with a charged one.

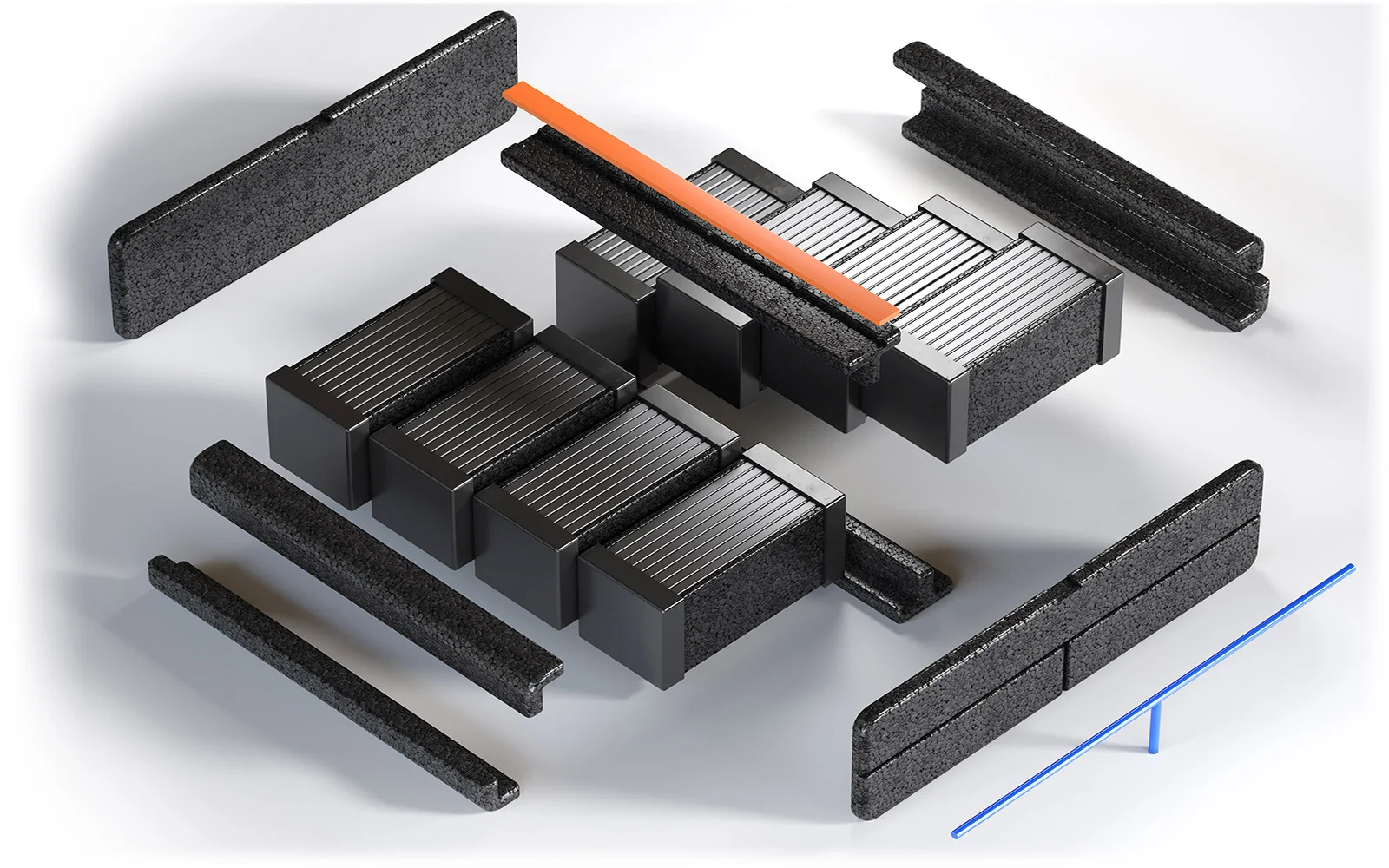

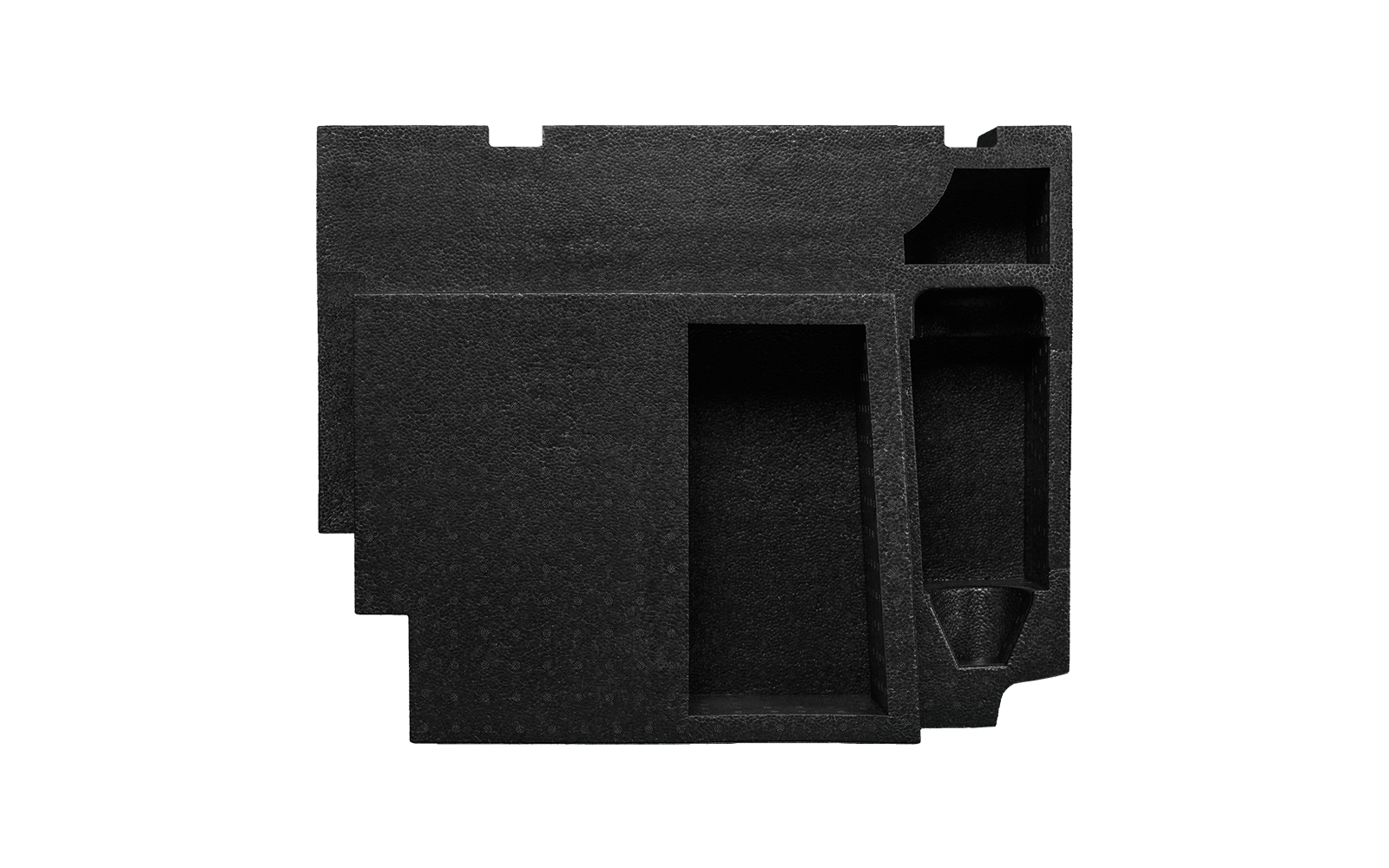

This, however, would require standardization of types, connections and battery dimensions, which is impracticable at present stage. Whereas the method available offhand is to lower the car’s own weight. It transfers directly to smaller energy consumption of its drive thus increasing the range. The car parts made from expanded polypropylene EPP allow for production of very light seats, bumpers, headrests or trunk elements. They are very durable and even up to 65% lighter than their counterparts made from hard plastic. Battery sets made from them feature also excellent heat properties, therefore ensuring excellent protection of batteries against extreme temperatures. Amortizing all shocks and impacts they extend battery cell durability and it also means extending of the durability of the electric car.